Date: 2026-01-23

Look at a printed circuit board. Notice the pads where components will sit—they might be shiny silver, have a golden tint, or a dull gray finish. That's not raw copper. What you're seeing is the PCB surface finish, a critical final coating applied to the board.

Why is this thin layer so important? Because bare copper, while a great conductor, is terrible at surviving in the real world. Left exposed, it oxidizes and corrodes, becoming impossible to solder reliably. The surface finish acts as a protective jacket and a prepared welding surface all in one. It keeps the copper pristine during storage and provides the perfect foundation for strong solder joints during assembly.

Choosing the right finish is a key decision that balances cost, performance, and reliability.

This is the classic, most well-known finish. The board is dipped in molten solder (now almost always lead-free), and then hot air blasts across it to level the coating.

What it's like: Imagine dipping something in melted wax and then blowing off the excess. It gets the job done but can leave a slightly uneven, globby surface.

The Good: It's the most affordable option and provides excellent, robust solder joints. It's very forgiving and has a long shelf life.

The Catch: The surface isn't perfectly flat. For modern, ultra-small components with pins very close together (fine-pitch), that unevenness can cause assembly problems. The high heat of the process can also stress thinner boards.

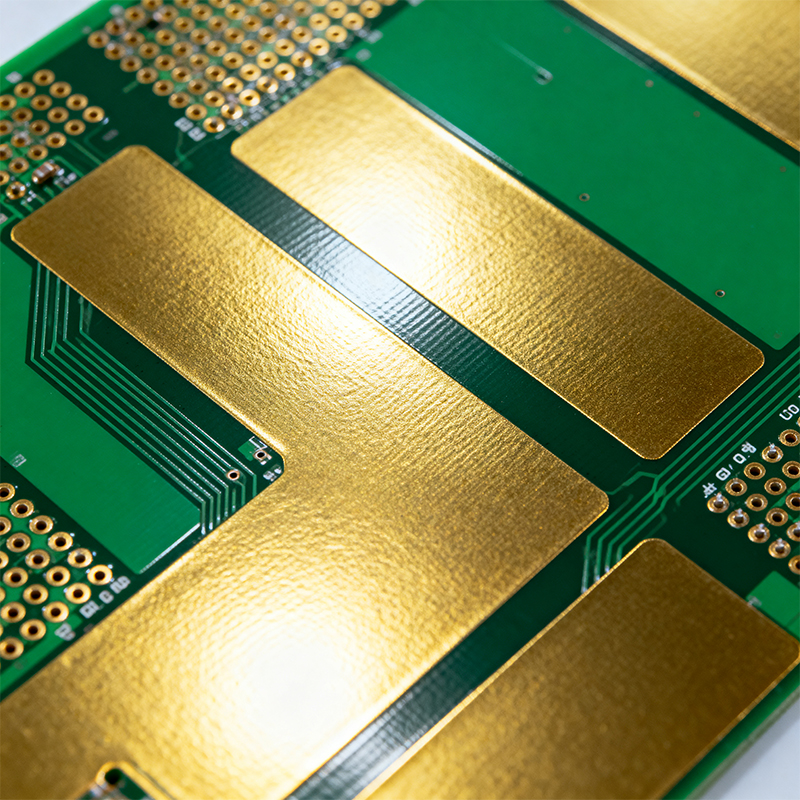

This is a two-layer, chemical coating. A layer of nickel is first deposited onto the copper, followed by a very thin layer of gold on top.

What it's like: A high-quality, gold-plated connector. It's flat, shiny, and looks professional.

The Good: It provides a perfectly flat surface, essential for today's tiny, complex chips. It has a very long shelf life, offers good electrical performance, and is ideal for contact points like edge connectors ("gold fingers").

The Catch: It's the most expensive common finish. The process must be tightly controlled, as a defect can lead to a "black pad" issue that weakens the solder joint.

OSP is a thin, water-based organic film that bonds to the copper, forming a protective layer.

What it's like: A clear, protective spray coating on metal. You can barely see it's there.

The Good: It's very flat and low-cost. It's also extremely environmentally friendly.

The Catch: The protective layer is fragile. It has a short shelf life, can be damaged by fingerprints, and is designed to be used once—it dissolves during soldering. This makes it great for fast, high-volume manufacturing but less suitable for boards that will be stored, handled extensively, or require rework.

These are two separate finishes with similar benefits. Both use a chemical process to deposit a thin, flat layer of pure metal (silver or tin) onto the copper.

What they're like: A smooth, electroplated coating. They offer a great balance between the flatness of ENIG and the lower cost of HASL.

The Good (Both): Very flat surface, good solderability, and a moderate price point.

Specific Notes:

Immersion Silver: Has fantastic performance for high-frequency signals but can tarnish (oxidize) if not stored properly.

Immersion Tin: Provides a great soldering surface but has a known (though manageable) risk of "tin whiskers"—tiny conductive hairs that can grow and cause shorts over many years in high-stress applications.

There's no single "best" finish. The right choice depends on your project:

What's on your board? If you have very small, dense components (like a fine-pitch BGA), you need a flat finish: choose ENIG, Immersion Silver, or Immersion Tin.

What's your budget? For the absolute lowest cost where perfect flatness isn't critical, HASL is the standard. For a balance of cost and flatness, look at OSP (for quick-turn production) or the immersion finishes.

How will the board be handled? If the boards will sit in storage, be manually handled, or need rework, avoid the fragile OSP. ENIG or HASL are more robust choices.

Any special needs? For high-frequency circuits, Immersion Silver or ENIG are superior. For wire bonding (a special assembly technique), ENIG is typically required.

The PCB surface finish is a small detail with a huge impact. It's the final, defining interface between your design and the physical world of manufacturing. Understanding these options helps you make an informed choice, ensuring your boards are not only functional but also reliable and cost-effective to build.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..