When designing a foldable smartwatch or a compact medical sensor, engineers often fixate on components like microchips or batteries—yet one seemingly small detail can make or break performance: PCB thickness. For Flexible Printed Circuits (FPCs) and Rigid-Flex Boards, thickness isn’t just a "size" choice; it directly impacts flexibility, durability, signal integrity, and even how well the board fits into the final device. Let’s unpack why thickness matters, and how the right choice transforms good designs into great ones.

FPCs’ biggest advantage is their ability to bend, twist, or fold—but thickness is the main driver of this flexibility. A 0.2mm-thick FPC (common in wearable bands) can fold 100,000+ times without cracking, while a 0.5mm-thick FPC of the same material will feel stiff and may split after just 10,000 folds.

Take a foldable smartphone’s inner hinge FPC:

-

If the FPC is too thick (e.g., 0.4mm), the phone’s hinge can’t fold smoothly, leading to a clunky user experience.

-

If it’s too thin (e.g., 0.1mm), the FPC tears easily during assembly or daily use—one major brand recalled 50,000 phones in 2024 because of this issue.

The sweet spot: Most consumer FPCs (wearables, foldables) use 0.15–0.25mm thickness. For industrial FPCs (e.g., robot arms that bend less frequently), 0.3–0.4mm works—they trade some flexibility for extra durability.

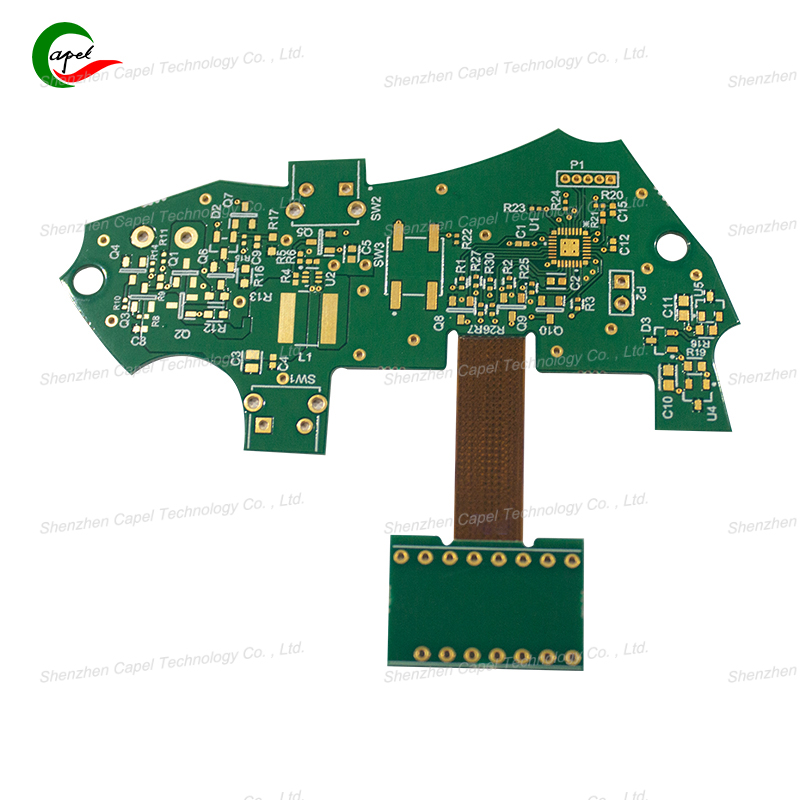

Rigid-Flex Boards combine stiff PCB sections (for components like chips) and flexible FPC sections (for bending). The danger here is mismatched thickness: if the rigid section is 1.6mm (standard for rigid PCBs) but the flexible section is only 0.15mm, the sudden thickness change creates stress at the "flex-rigid junction"—causing delamination (peeling) over time.

A European automotive supplier learned this the hard way:

-

They used a 1.6mm rigid section and 0.18mm flexible section for a car’s dashboard sensor FPC.

-

After 6 months of vibration (from driving), 8% of boards delaminated because the thin flexible section couldn’t handle the stress from the thick rigid part.

Fix: Taper the rigid section’s edge to match the flexible section’s thickness (e.g., 1.6mm rigid → 0.3mm taper → 0.18mm flexible). This "smooth transition" cuts stress by 70%, and the supplier’s delamination rate dropped to 0.5%.

For devices that send fast data (e.g., 5G IoT sensors, medical ultrasound machines), PCB thickness affects signal quality. Thicker dielectric cores (the non-conductive layer between copper lines) reduce "crosstalk"—when signals from one copper line leak into another, causing data errors.

A U.S. IoT firm designing a 5G weather sensor faced this problem:

-

They initially used a 0.2mm-thick FPC with a thin dielectric core (0.1mm).

-

The sensor’s data kept dropping because of crosstalk from nearby antennas.

Solution: Switch to a 0.3mm-thick FPC with a 0.18mm dielectric core. The thicker core blocked crosstalk, and the sensor now transmits 99.9% accurate data—critical for predicting severe weather.

Even the best-performing FPC or Rigid-Flex Board is useless if it doesn’t fit into the device. Thickness directly impacts how many components you can stack and how the board fits into tight spaces.

Consider a tiny glucose monitor (about the size of a thumb):

-

The monitor’s enclosure is only 0.8mm thick. Using a 0.3mm-thick FPC leaves enough space for a battery (0.3mm) and a sensor (0.2mm)—perfectly fitting the enclosure.

-

If the FPC were 0.4mm thick, the components would bulge out, making the monitor uncomfortable to wear.

For Rigid-Flex Boards, thickness also affects component mounting: thicker rigid sections (e.g., 1.2mm) can hold heavier components (like large capacitors), while thinner rigid sections (0.8mm) are better for lightweight devices (e.g., earbuds).

Thicker PCBs generally handle mechanical stress better— but only up to a point. For FPCs used in high-vibration environments (e.g., industrial robots), a slightly thicker FPC (0.3mm vs. 0.2mm) resists tearing from constant movement. However, for FPCs that fold hundreds of times a day (e.g., smartwatch hinges), a thicker board will wear out faster.

A Chinese robot maker found this balance:

-

They use 0.35mm-thick FPCs for robot arms (which bend slowly but 承受 heavy loads).

-

For the robot’s finger joints (which fold quickly), they use 0.2mm-thick FPCs—thinner enough to fold easily, but durable enough to last 2 years.

PCB thickness isn’t a random choice. For FPCs, prioritize flexibility and fit for wearables/foldables, and thicker cores for high-speed data. For Rigid-Flex Boards, focus on balancing rigid and flexible section thickness to avoid delamination. The best approach? Start with your device’s goals (e.g., "must fold 50,000 times" or "needs 5G signal") and work backward to choose thickness—test small batches first, then scale up. Get the thickness right, and you’ll avoid costly redesigns, improve performance, and create devices that stand out.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.