Why is the Testing Stage So Critical on a PCBA Production Line?

Picture this: You’ve designed a great product, and the PCBA boards are manufactured. If you assembled them directly into final products and found that 2 out of 10 units didn’t work, what would you do? Disassemble, troubleshoot, replace components, retest… Your costs would skyrocket, and your project timeline would be severely delayed.

This is why professional PCBA manufacturers treat testing as a non-negotiable part of the process. It’s not about “finding faults” for the sake of it. It’s about identifying and resolving issues at the earliest possible stage and the lowest possible cost, preventing defective boards from moving down the line and causing much greater losses.

Simply put, testing is your quality insurance and cost control valve.

What Are These Common Tests on a PCBA Line Actually Checking?

1. Flying Probe / In-Circuit Test

This is often the first electrical test. Its goal is straightforward: to check if all the intended connections on the PCB are made (continuity), if there are any unintended connections (shorts), or missing connections (opens).

-

How it works: Precise probes make contact with test points on the board, rapidly checking the connectivity of networks, much like tracing a circuit diagram.

-

When it’s used: Typically performed after SMT assembly and before functional testing. It quickly catches basic process defects like solder bridges or poor connections.

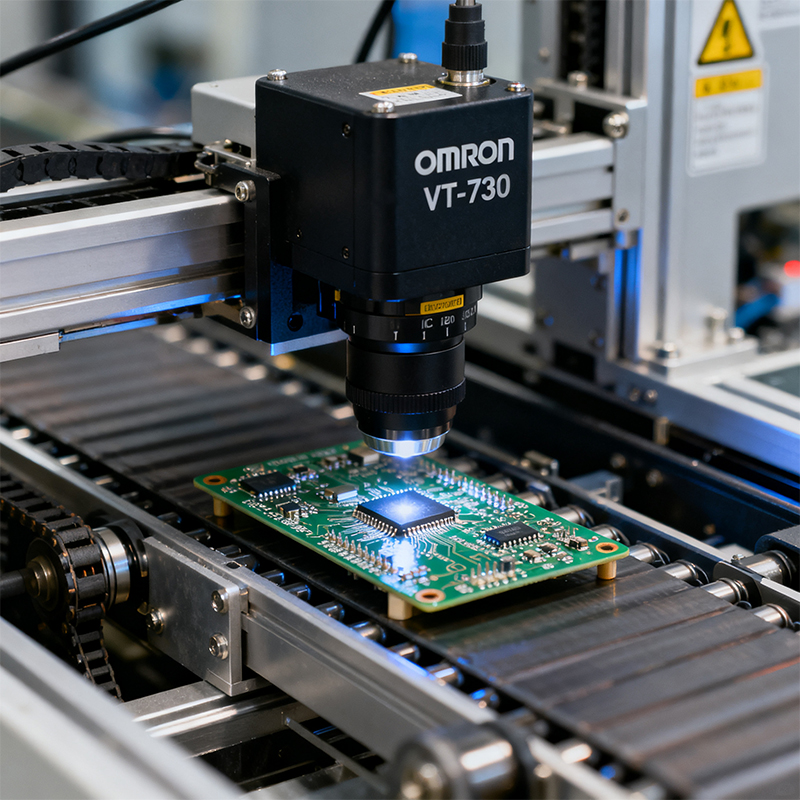

2. AOI Inspection

This is the “eagle eye” on the production line. It doesn’t test electrical performance but takes high-resolution “photos” of the PCBA and compares them to a standard image.

-

What it looks for: Checks for component errors (wrong part, reversed polarity), misalignment, missing parts, and assesses solder joint shape and solder paste volume.

-

Why it matters: Catches visual defects that human eyes might miss due to fatigue, especially critical as components get smaller and inspection becomes more challenging.

3. X-Ray Inspection

For things the eye can’t see, you need X-rays. A prime example is the area under a BGA-packaged chip, where the solder joints are completely hidden by the component body.

-

What it looks for: Primarily inspects the quality of hidden solder joints for issues like voids, bridges, or insufficient solder.

-

Typical use: Often a mandatory check for BGAs, QFNs, and other hidden-joint components in high-reliability applications like automotive or medical electronics.

4. Functional Test

This is the test that most closely mimics the real-world operation of your product. In simple terms, it involves powering up the PCBA, connecting necessary interfaces, simulating its actual working environment, and verifying it performs its intended functions.

-

What it tests: For example, for a Bluetooth speaker motherboard, a functional test would check: Does it power on correctly? Can the Bluetooth be discovered and paired? Is the audio output normal during playback? Do the buttons work?

-

Core value: It validates the system-level functionality of the PCBA as a whole. It’s the final confidence check before delivery.

5. Programming & Burn-in / Aging Test

-

Programming: Also called “burning” or “flashing,” this is where the software (firmware) is loaded into the main controller chip on the production line. It ensures every board leaves the factory with the “correct brain.”

-

Burn-in / Aging Test: Sometimes called “soaking.” The PCBA is powered on and operated in a controlled temperature environment for a set duration (e.g., 8, 24, or more hours). The goal is to “stress” the board during early operation to identify and screen out units with latent defects that might fail early in the customer’s hands (“infant mortality”).

With So Many Tests, How Do I Choose for My Project?

There’s no one-size-fits-all answer. The strategy depends on:

-

Product Complexity: A simple LED driver board might only need basic continuity testing, while a complex communication module might require a full suite of ICT, AOI, X-Ray, and FCT.

-

Application Field: Consumer electronics may prioritize cost and speed. Products for automotive, medical, or industrial control demand极高的 reliability, which dictates more comprehensive and stringent testing.

-

Volume and Cost Considerations: Bed-of-nails test fixtures have an upfront cost, making them more suitable for high-volume production. Flying probe tests require no fixture and are better for low-volume, high-mix scenarios.

A good PCBA manufacturing partner won’t apply the same test template to every customer. Instead, they should work with you to develop a rational and efficient test strategy based on your product’s characteristics, budget, and risk tolerance. The goal is to find the optimal balance between quality, cost, and delivery time.

At Kaboer’s factory in Shenzhen, testing is a standard, integral part of our production flow. We believe that every bit of effort invested in testing upfront saves our clients significant trouble and risk down the line.

We hope this overview helps demystify PCBA testing.

If you have questions about a test strategy for a specific product, we’re here to discuss. The Kaboer team can provide more targeted Design for Manufacturing (DFM) and test feasibility analysis based on your specific design.