Date: 2025-12-08

Getting a new electronic product off the ground? Whether you're a startup founder with a brilliant idea or an engineer at an established company, the journey from concept to a finished, working device can feel complex. One of the most critical steps in that journey is Printed Circuit Board Assembly, or PCBA. But what exactly is it, and why should you care about who handles it for you?

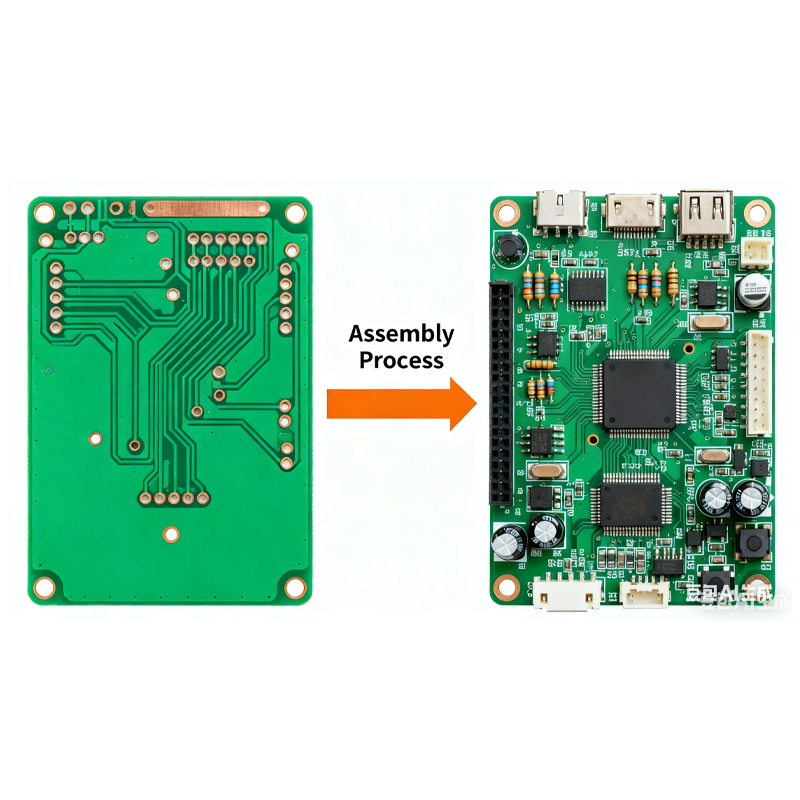

Think of your product's electronic system like a human body. The Printed Circuit Board (PCB) is the skeleton—it's the bare green board that provides structure and pathways (the copper traces) for signals to travel. Printed Circuit Board Assembly (PCBA) is the complete, functioning system. It's what happens when that skeleton is populated with all its vital organs: the microchips (the brain), resistors and capacitors (supporting systems), and connectors (the senses and limbs). Without a reliable PCBA process, your product simply won't work as intended.

At Kaboer, we specialize in turning your designs into robust, high-quality assembled circuit boards. We know that choosing the right PCBA partner isn't just a procurement decision; it's a strategic choice for your product's quality, timeline, and ultimate success.

PCBA is the invisible engine inside nearly every modern device. If your product needs to think, communicate, power on, or sense its environment, it needs a reliably assembled circuit board.

Consumer Tech You Love: The seamless function of your smartphone, smartwatch, wireless earbuds, and gaming consoles all hinge on advanced, miniaturized PCBA.

Innovations Changing Industries: From life-saving portable medical monitors and diagnostic equipment to the advanced driver-assistance systems (ADAS) and battery management in electric vehicles, reliability in PCBA is non-negotiable.

The Infrastructure of Modern Life: The routers that give you Wi-Fi, the servers hosting data, 5G towers, and industrial automation robots all depend on durable, custom PCB assemblies.

The Cutting Edge: IoT sensors, AI hardware, drones, and aerospace technology are pushing the limits of what PCBA can do, requiring expertise in advanced materials and ultra-precise assembly.

Choosing Kaboer for your Printed Circuit Board Assembly means choosing a partner invested in smoothing your path to market. We move beyond being just a vendor to become an extension of your team. Here’s how we make your life easier:

1. We Handle the Heavy Lifting, So You Can Focus on Innovation.

Managing PCBA in-house means juggling PCB fabrication, global component sourcing, specialized equipment, and a mountain of logistics. We consolidate all that into one clear, accountable process. You share your vision and design files, and we manage the rest—from sourcing genuine components (even in tough supply markets) to rigorous testing and on-time delivery. This turns a major capital expenditure into a predictable operational cost.

2. We Catch Problems Before They Cost You Time and Money.

Our engineering support begins early. Before any board is built, we offer a Design for Manufacturability (DFM) review. It's like having a seasoned guide check your map before a big hike. Our engineers look at your design to spot potential assembly issues, suggest component alternatives during shortages, and optimize layouts for reliability. This proactive step is one of the biggest values we provide, preventing headaches down the line.

3. We Build Quality In, Not Inspect It Out.

Trust is everything. We build it through a multi-layered inspection process that goes far beyond a simple visual check:

Automated Optical Inspection (AOI): High-resolution cameras scan every board for missing or misaligned components.

X-ray Inspection: For critical components like BGAs where solder joints are hidden underneath, we use X-rays to ensure perfect, invisible connections.

Functional Testing: Finally, we power up your board and test it to ensure it performs exactly as your design specified.

4. We Scale When You're Ready.

Whether you need 5 prototype units in a week to secure funding or 50,000 units for a global launch, our systems are built for agility. Our quick-turn prototype service gets you working samples fast, and our production lines seamlessly ramp up to volume manufacturing without sacrificing the quality you validated in the prototypes.

The complexity of Printed Circuit Board Assembly shouldn't be the barrier between your idea and the market. With the right partner, it becomes a streamlined, reliable step in your journey.

At Kaboer, we combine technical expertise with a commitment to clear communication and partnership. We're here to answer your questions, provide transparent quotes, and deliver assembled boards that give you confidence.

Stop wrestling with manufacturing complexities. Let's talk about how we can bring your next product to life with reliability and precision.

Contact Kaboer today for a free, no-obligation consultation on your PCBA project.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..