Walk into an electronics factory, and you’ll hear a common question: "Should we use rigid-flex PCBs or flexible PCBs (FPCs)?" The answer isn’t "one is better"—it depends on the industry, the device’s job, and what matters most: cost, durability, space, or flexibility.

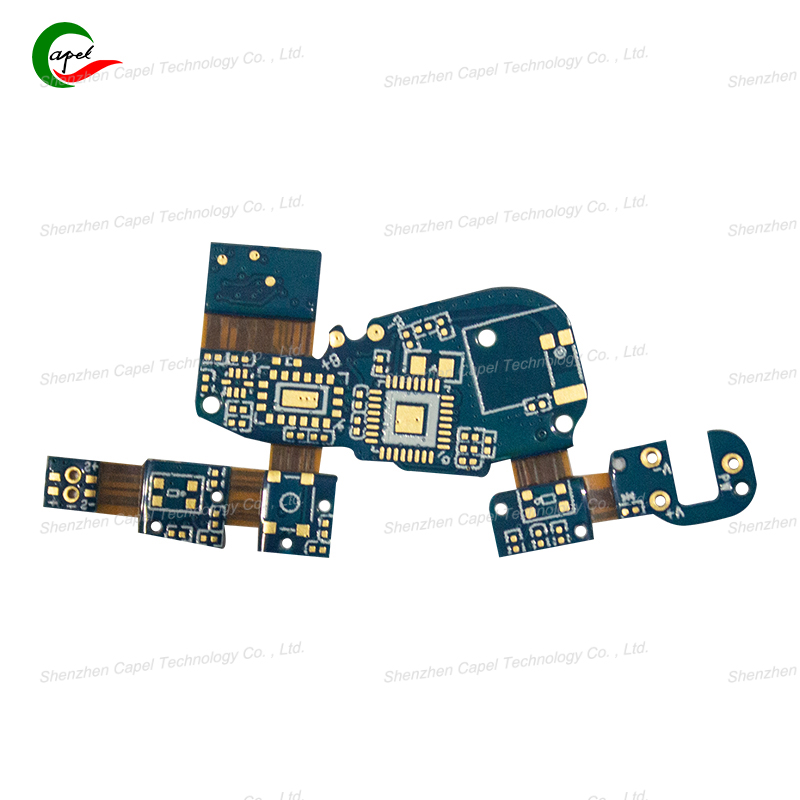

Rigid-flex PCBs mix rigid FR4 layers (for heavy components) and flexible polyimide layers (for bending). FPCs are fully flexible (no rigid parts). A foldable phone might need rigid-flex; a simple smartwatch sensor might need FPCs. Below, we break down how four key industries—automotive, consumer electronics, medical devices, and industrial machinery—choose between them, using real examples from Tesla, Apple, Medtronic, and Siemens.

Cars are harsh environments: high temperatures (-40°C to 125°C), constant vibration, and long lifespans (10+ years). Automotive engineers prioritize durability and reliability over cost—since a PCB failure can cause a breakdown.

- High-Stress Areas: Engine sensors, battery management systems (BMS), and infotainment systems need to handle vibration and heat. Rigid-flex’s rigid layers hold heavy chips (e.g., BMS microcontrollers), while flexible layers absorb vibration. Tesla uses rigid-flex PCBs in its Model Y’s BMS; vibration-related failures dropped by 65% vs. FPCs.

- Multi-Component Zones: Areas with multiple parts (e.g., dashboard displays) need rigid sections to mount components and flexible sections to route around other parts. Ford switched to rigid-flex in its F-150’s dashboard; assembly time cut by 30% (no need to wire multiple FPCs).

- Simple, Low-Stress Sensors: Door lock sensors, seat position sensors, or temperature sensors don’t need heavy components. FPCs are cheaper and thin enough to fit in tight spaces. Toyota uses FPCs in its Camry’s seat sensors; cost per unit is 40% lower than rigid-flex.

Consumer electronics (phones, earbuds, wearables) chase small size, light weight, and cost control. A $100 smartwatch can’t afford expensive rigid-flex—unless it needs to fold.

- Foldable Devices: Foldable phones (Samsung Galaxy Z Flip) or 2-in-1 laptops need to bend and hold powerful components (processors, displays). Rigid-flex’s mix of rigid (for chips) and flexible (for hinges) layers is the only option. Samsung’s foldable phones use rigid-flex; bending-related failures are 80% lower than if they used FPCs (which lack rigid mounting for heavy chips).

- Complex Wearables: High-end smartwatches (Apple Watch Ultra) with multiple sensors (GPS, heart rate, altimeter) need rigid sections for chips and flexible sections to fit around batteries. Apple switched to rigid-flex; sensor signal consistency improved by 50% (no loose FPC connections).

- Simple Wearables/Budget Phones: Basic fitness bands (Fitbit Inspire) or budget smartphones ($200+) only need simple connections (battery to screen). FPCs are thin, light, and cheap. Fitbit uses FPCs in its budget trackers; weight is 30% lower than rigid-flex, and cost per unit is $1.50 vs. $3.00 for rigid-flex.

- Tiny Gadgets: Wireless earbuds (AirPods) have no space for rigid layers. FPCs snake around batteries and speakers—Apple’s AirPods use FPCs; they fit in the 1.5cm-wide earbud, while rigid-flex would be too bulky.

Medical devices need sterilizability, biocompatibility, and reliability (a failure could harm patients). Cost is less important than safety—but simple devices still use FPCs.

- Implantable Devices: Pacemakers or insulin pumps need to bend with the body and hold long-lasting batteries/chips. Rigid-flex’s rigid layers protect components from body fluids, while flexible layers move with organs. Medtronic uses rigid-flex in its pacemakers; lifespan extended to 10 years (vs. 7 years with FPCs, which wear out faster).

- Complex Tools: Endoscopes (used to see inside the body) need to bend around organs and carry cameras/sensors. Rigid-flex’s rigid sections mount the camera, flexible sections bend—Olympus switched to rigid-flex; endoscope failure rates dropped by 70% (no FPC wire disconnections).

- External, Simple Monitors: Basic glucose monitors (OneTouch Verio) or blood pressure cuffs only need to connect a sensor to a display. FPCs are cheap, easy to sterilize, and thin enough to fit in the device. OneTouch uses FPCs; cost per unit is 50% lower than rigid-flex, and sterilization doesn’t damage the flexible layers.

Industrial machines (robots, factory conveyors) operate 24/7 in dusty, vibrating environments. They need long-term durability (5+ years) and resistance to dust/chemicals.

- Robotic Arms: Robotic arms bend 10,000+ times a day and need to mount motors/sensors. Rigid-flex’s rigid layers hold heavy components, flexible layers absorb vibration—Siemens uses rigid-flex in its robotic arms; maintenance costs cut by 40% (no FPC replacements every 2 years).

- Control Panels: Factory control panels have multiple buttons, screens, and sensors. Rigid-flex’s rigid sections mount the screen/chips, flexible sections route around buttons—Bosch switched to rigid-flex; panel failure rates dropped by 55% (no loose FPC wires).

- Light Sensors/Non-Moving Parts: Temperature sensors on conveyors or dust detectors don’t move or need heavy components. FPCs are cheap and easy to install. A German factory uses FPCs in its conveyor sensors; cost per unit is 35% lower than rigid-flex, and they last 5+ years (no vibration stress).

Rigid-flex PCBs and FPCs aren’t competitors—they’re tools for different jobs. The choice boils down to what the industry values most:

- Automotive: Durability first (rigid-flex for high-stress parts, FPCs for simple sensors).

- Consumer Electronics: Size/cost first (rigid-flex for complex foldables, FPCs for budget/small gadgets).

- Medical: Safety/reliability first (rigid-flex for implants, FPCs for simple monitors).

- Industrial: Longevity first (rigid-flex for moving parts, FPCs for static sensors).

A Tesla engineer wouldn’t use an FPC in a battery management system—just like a Fitbit engineer wouldn’t use rigid-flex in a budget tracker. The best choice is the one that solves the industry’s unique problem: whether it’s surviving a car’s engine heat, fitting in an earbud, or keeping a pacemaker running for 10 years.

At the end of the day, it’s not about "rigid-flex vs. FPC"—it’s about "right PCB for the right job."

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.