Imagine a satellite’s PCB failing 300km above Earth—all because it couldn’t handle the cold of space (-150°C). Or a factory’s FPC melting in a high-temperature oven (-200°C). Extreme temperatures (below -40°C or above 125°C) are electronics’ worst enemy: they warp PCB substrates, crack FPC traces, and destroy solder joints.

For devices in harsh environments—aerospace, automotive engines, polar research gear, or industrial ovens—standard FPC/PCB materials (like FR4 for PCBs or basic PI for FPCs) won’t cut it. The solution lies in two steps: choosing temperature-resistant materials and adding protective measures. Below are proven strategies for both high and low extreme temperatures, using examples from NASA, Tesla, and polar research teams.

High temperatures (e.g., car engine bays, industrial furnaces, aircraft engines) soften substrates, corrode traces, and melt adhesives. A test by the IPC found that standard FR4 PCBs fail after 100 hours at 150°C—far less than the 10,000+ hours needed for industrial use.

-

PCB Substrates: Replace FR4 (max 130°C) with PTFE (Teflon) (max 260°C) or ceramic-filled PI (max 300°C). NASA uses PTFE PCBs in rocket engines; they survive 200°C for 5,000+ hours.

-

FPC Substrates: Upgrade from standard PI (max 200°C) to glass-reinforced PI (GRPI) (max 250°C) or polyamide-imide (PAI) (max 300°C). Tesla uses GRPI FPCs in Model 3 engine sensors; they handle 180°C engine heat with 0 failures in 3 years.

-

Trace & Solder Materials: Use thick copper traces (2oz+—resists oxidation at high temps) and high-temperature solder (e.g., Sn-Ag-Cu with 217°C melting point, vs. standard 183°C). A Chinese industrial oven maker switched to this combo; trace corrosion dropped by 80%.

-

Conformal Coatings: Apply a heat-resistant coating (e.g., Dow’s silicone-based coating, max 260°C) over FPC/PCB. This prevents substrate oxidation and trace corrosion. Boeing uses this on aircraft engine PCBs; high-temp failures fell by 75%.

-

Metal Heat Shields: Add a thin aluminum shield around the FPC/PCB to block direct heat (e.g., from a car engine). Ford’s F-150 uses these shields; PCB temps inside the engine bay dropped by 40°C.

-

Thermal Vias: Drill small holes (thermal vias) in PCBs to channel heat away from components. A semiconductor factory added thermal vias to its oven PCBs; component temps fell by 30°C, extending lifespan by 2x.

Low temperatures (e.g., polar research, space, cold-storage warehouses) make substrates brittle, shrink traces, and crack solder joints. Standard PI FPCs crack after 1,000 bends at -50°C—while polar gear needs to work at -60°C for years.

-

PCB Substrates: Avoid FR4 (becomes brittle below -40°C) — use modified PI (stays flexible down to -196°C) or PTFE (works at -269°C, near absolute zero). A polar research team uses PTFE PCBs in their ice sensors; they’ve worked at -60°C for 2 years with no cracks.

-

FPC Substrates: Use low-temperature PI (e.g., DuPont’s Kapton HN, flexible at -269°C) instead of standard PI. SpaceX uses this FPC in Starlink satellites; they handle space’s -150°C temps without trace cracking.

-

Adhesives & Solder: Use cold-resistant adhesives (e.g., 3M’s epoxy-based adhesives, work down to -80°C) and low-temperature solder (e.g., Sn-Bi, melts at 138°C but stays strong at -50°C). A cold-storage tech firm switched to this; solder joint failures dropped by 90%.

-

Insulation Layers: Wrap FPC/PCB in a thin, flexible insulation (e.g., foam-based insulation) to trap heat from the device’s own components. A Norwegian oil rig uses this on its subsea sensors (which face -50°C); PCB temps stay above -30°C.

-

Heating Elements: Add tiny, low-power heaters (e.g., resistive heaters) near critical components. NASA’s Mars rovers use these to keep PCBs above -40°C; no cold-related failures in 10+ years on Mars.

-

Avoid Sharp Bends in FPCs: Cold makes FPCs stiffer—sharp bends (≤0.5mm radius) cause cracking. A polar drone maker routed FPCs with 2mm+ bend radii; cold-induced cracks dropped to 0% from 25%.

Some strategies work for any extreme temperature—they boost overall durability and reduce temperature-related stress:

-

Minimize Component Density: Crowded PCBs trap heat (high temps) or cool too fast (low temps). Spread components out to let air circulate. A military equipment maker did this; PCB temp variation dropped by 25°C.

-

Use Stress-Relief Routing: For FPCs, use curved traces (not straight lines) to absorb temperature-induced expansion/contraction. Samsung uses this in its extreme-temperature FPCs; expansion-related trace damage fell by 60%.

-

Seal Against Moisture: Moisture freezes (low temps) and expands, cracking PCBs—or boils (high temps) and corrodes traces. Use IP68-rated enclosures or waterproof gaskets. A marine tech firm sealed its PCBs; moisture-related failures dropped by 85%.

-

Test Under Realistic Conditions: Use environmental chambers to simulate extreme temps (e.g., -60°C to 200°C) and cycle tests (heat → cold → heat). Tesla tests its engine FPCs for 1,000 temperature cycles; only 1% fail, vs. 15% without testing.

FPCs and PCBs don’t have to fail in extreme temperatures—you just need to choose materials that can handle the heat or cold, then add protection to reduce stress. NASA’s rockets, Tesla’s engines, and polar research gear all prove this: with the right combo, electronics can work at -269°C (near absolute zero) or 300°C (rocket engine heat).

The key mistake? Using standard materials in extreme environments. A factory once tried to use FR4 PCBs in a 180°C oven—90% failed in a month. After switching to PTFE PCBs and adding heat shields, failure rates dropped to 1%.

For engineers, the lesson is clear: extreme temperature design isn’t about "overengineering"—it’s about matching materials and protection to the environment. Whether your device is in a car engine, a polar ice field, or space, the right choices will keep it running.

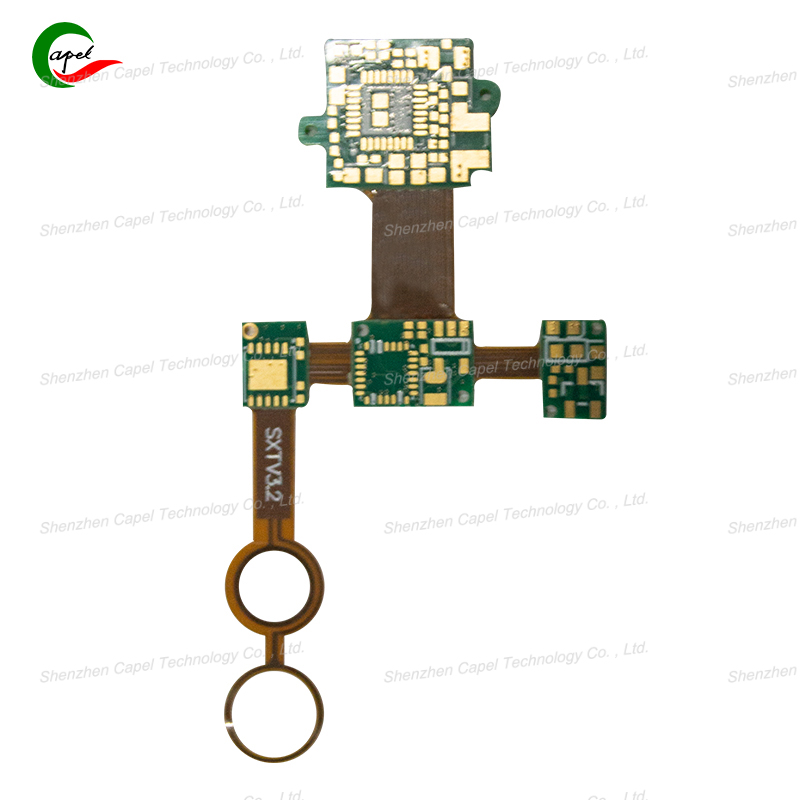

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.