Date: 2025-12-25

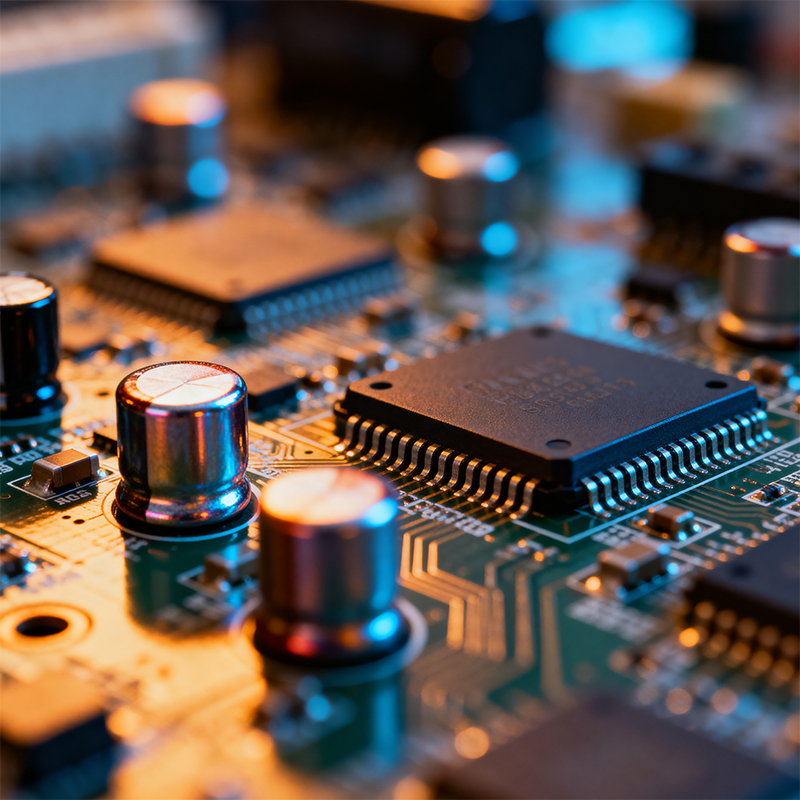

SMD Printed Circuit Board, often referred to as an SMD PCB, represents the standard in modern electronics manufacturing. It is a printed circuit board (PCB) specifically designed for the assembly of Surface Mount Devices (SMDs). Unlike traditional boards for through-hole components, an SMD PCB features flat, metallic pads (called solder pads) on its surface. These pads allow tiny, leadless electronic components to be placed and soldered directly onto the board, enabling the miniaturization, automation, and high performance of today's electronic devices.

This guide explains everything you need to know about SMD PCB technology.

At its core, an SMD PCB is defined by its compatibility with Surface Mount Technology (SMT). The key differentiator lies in the component assembly method. Let's compare it with the older Through-Hole Technology (THT):

| Feature | SMD PCB (Surface Mount Technology) | THT PCB (Through-Hole Technology) |

|---|---|---|

| Component Leads | Components have small metal tabs or are leadless. | Components have long wire leads. |

| Mounting Method | Components are placed and soldered onto the surface of the board. | Component leads are inserted into holes drilled through the board and soldered on the opposite side. |

| PCB Design | Features flat copper solder pads. No holes are needed for most components. | Requires a drilled hole for each component lead. |

| Board Space | Extremely efficient. Components can be placed on both sides of the board. | Less efficient. Drilling limits routing space and component density. |

| Automation | Fully automatable with high-speed pick-and-place machines. | Partial automation for insertion is possible, but often involves manual steps. |

| Typical Applications | Smartphones, laptops, wearables, and virtually all modern, compact electronics. | Power supplies, prototypes, or devices where mechanical strength is prioritized over size. |

An SMD PCB is a layered structure. From bottom to top, the key elements relevant to SMT assembly are:

Substrate (Base Layer): Typically made of fiberglass-reinforced epoxy (like FR-4), this rigid or flexible core gives the board its mechanical strength.

Copper Traces: Thin layers of copper are laminated and etched to form the electrical pathways connecting different points on the board.

Solder Mask: The iconic green (or other colored) layer that covers the copper traces. It insulates the traces and prevents solder bridges during assembly. Openings in this mask define the solder pads where components will sit.

Silkscreen: The white (or other color) lettering and symbols printed on top. It labels components (R1, C5, U3) and provides assembly guides, but plays no electrical role.

Surface Finish: A critical coating applied over the exposed copper solder pads. It protects the copper from oxidation and ensures a reliable solder joint. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Turning a bare SMD PCB into a functional assembly is a highly automated, precise sequence:

Solder Paste Printing: A stainless steel stencil is aligned over the PCB. Solder paste (a mixture of tiny solder balls and flux) is squeezed through the stencil openings onto the solder pads. Solder Paste Inspection (SPI) often follows to ensure correct volume and alignment.

Component Placement: A high-speed pick-and-place machine picks SMD components from reels, sticks, or trays using a vacuum nozzle. It then places them with extreme precision onto their pre-programmed locations on the solder-paste-coated pads.

Reflow Soldering: The populated PCB travels on a conveyor through a reflow oven. It passes through carefully controlled heating zones that melt the solder paste, forming permanent, reliable electrical and mechanical solder joints as it cools.

Inspection & Testing: Automated Optical Inspection (AOI) systems use cameras to scan the board for defects like missing components, misalignment, or solder bridging. For complex components like Ball Grid Arrays (BGAs), X-ray inspection is used to see hidden solder joints. Electrical tests (like ICT or Flying Probe) verify circuit functionality.

SMD PCB assembly dominates the industry due to compelling benefits:

Miniaturization: SMD components are much smaller than their through-hole counterparts, enabling smaller and lighter end products.

Higher Density & Performance: Components can be placed on both sides of the board with very fine spacing, allowing more complex functionality in less space. Shorter electrical paths also improve high-frequency signal performance.

Cost-Effectiveness at Scale: The process is highly automated, reducing labor costs. It also uses less raw material (no need to drill many holes) and enables faster production speeds.

Design Flexibility: SMT is compatible with advanced board types like High-Density Interconnect (HDI) and Flexible PCBs (FPC), which are crucial for cutting-edge applications like foldable phones and advanced automotive electronics.

SMD PCBs are the foundation of nearly every modern electronic sector:

Consumer Electronics: Smartphones, tablets, laptops, wearables.

Telecommunications: 5G infrastructure, network routers, base stations.

Automotive: Advanced Driver-Assistance Systems (ADAS), infotainment, powertrain controls.

Industrial & Medical: Automation controls, diagnostic equipment, monitoring devices.

The future of SMD PCBs is linked to ongoing trends:

Further Miniaturization: Components continue to shrink (e.g., from 0402 to 0201 metric sizes), pushing the limits of placement and soldering precision.

Advanced Materials: The use of flexible substrates and new composite materials supports innovative product forms and higher reliability.

Hybrid Electronics: Research is exploring the integration of printed electronics with traditional SMD components, opening new design possibilities for lightweight and sustainable electronics.

AI-Driven Manufacturing: Artificial intelligence is being integrated for improved design optimization, predictive quality control, and real-time process adjustments.

Q1: Are SMD and SMT the same thing?

A: No, they are related but distinct terms. SMD (Surface Mount Device) refers to the component itself (e.g., a resistor, capacitor, or chip). SMT (Surface Mount Technology) refers to the entire process and methodology of assembling those components onto a PCB.

Q2: What does a "double-sided SMD PCB" mean?

A: It means that SMD components are placed and soldered on both the top (primary side) and bottom (secondary side) of the circuit board. This is a standard technique to maximize space utilization.

Q3: Can an SMD PCB also have through-hole components?

A: Yes. Such boards are called mixed-technology PCBs. The SMD components are typically placed and reflow-soldered first, followed by the insertion and soldering (often via wave soldering) of the through-hole components.

Q4: What are the main challenges in SMD PCB assembly?

A: Key challenges include managing thermal profiles for diverse components, preventing tombstoning (one end of a component lifting), inspecting hidden solder joints (like under BGAs), and sourcing specialized components. Successful assembly requires precise design for manufacturability (DFM), high-quality materials, and strict process control.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..