Date: 2025-12-25

Circuit board repair is a systematic process of diagnosing faults and restoring functionality to a printed circuit board assembly. While basic issues can sometimes be addressed with proper tools and techniques, complex repairs require professional expertise. This guide outlines the fundamental principles, common repair methods, and critical considerations for dealing with faulty PCBs in a manufacturing or professional setting.

Before any physical repair, conduct a thorough assessment:

Visual Inspection: Use magnification (microscope or loupe) to examine the entire board. Look for burn marks, cracked components, bulging capacitors, broken traces, cold solder joints, or signs of corrosion.

Understand the History: Note the symptoms of failure and the board's operating environment (e.g., power surge, liquid damage, physical shock).

Electrostatic Discharge (ESD) Safety: Always work on an ESD-safe mat and use a grounded wrist strap. PCBs contain sensitive components easily damaged by static electricity.

Power Isolation: Ensure the board is completely disconnected from any power source and that large capacitors are safely discharged.

Repair is impossible without accurate diagnosis. Follow this logical flow:

Power Supply Check: Use a multimeter to verify all voltage rails (e.g., 3.3V, 5V, 12V) are present and within specification. A faulty regulator or short circuit is a common culprit.

Continuity Testing: Check for open circuits (broken traces or vias) and short circuits (bridged solder, failed components). Use the multimeter's continuity or resistance mode.

Component-Level Testing:

Passive Components: Test resistors, capacitors, and inductors out of circuit (if possible) for correct values.

Diodes & Transistors: Use the multimeter's diode test function to check for opens/shorts.

Integrated Circuits (ICs): Direct IC testing is complex. Focus on verifying power and ground pins, checking for overheating, and inspecting solder joints. Logic analyzers or oscilloscopes may be needed for signal verification.

Thermal Imaging: A thermal camera can quickly identify components that are overheating (indicating failure) or unusually cold (indicating no power).

Once the fault is isolated, proceed with the appropriate repair method.

A. Reflowing/Resoldering Solder Joints

Use: Fix "cold solder joints" (dull, grainy, cracked connections) or minor bridges.

Method: Apply flux to the joint, then use a temperature-controlled soldering iron or hot air rework station to re-melt the solder, allowing it to flow properly. Remove excess solder with desoldering braid.

B. Replacing Faulty Components

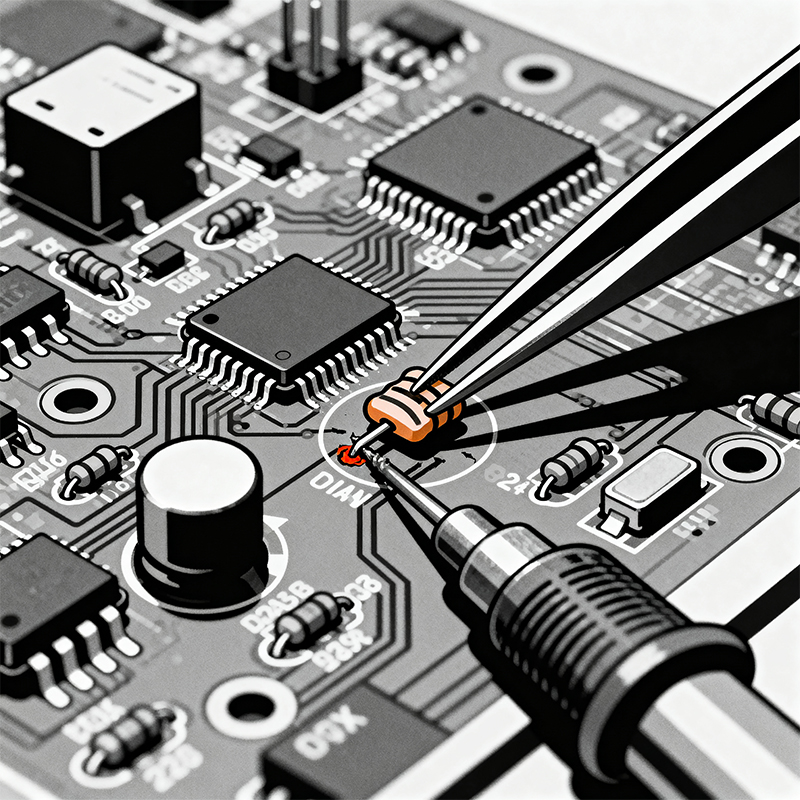

Desoldering: For SMD components, use a hot air gun with the correct nozzle to evenly heat all leads, then lift the component with tweezers. For through-hole parts, use a desoldering pump or vacuum tool to remove solder from the holes.

Resoldering: Clean the pads, apply new flux, place the new component (correct orientation!), and solder it in place. For SMDs, solder paste and hot air are often used.

C. Repairing Damaged Traces (PCB "Surgery")

For Scratched/Cut Traces: Gently scrape off the solder mask from both ends of the broken trace. Tin the exposed copper. Use a thin enameled wire to bridge the gap, soldering it to each tinned point. Secure the wire and insulate it with conformal coating or epoxy.

For Damaged Pads/Vias: If a pad is lifted, a "via repair kit" or a small wire can be used to recreate the connection to the next logical point in the circuit.

D. Cleaning Corrosion

Use: For water or flux damage.

Method: Clean with isopropyl alcohol (IPA) and a soft brush. For severe corrosion, specialized cleaning solutions may be required. Corroded traces may need repair afterward.

A repair is not complete until functionality is verified.

Visual Re-inspection: Check your work under magnification.

Continuity/Power Check Again: Re-test for shorts and verify power rails.

Basic Functional Test: If possible, power the board in a controlled manner (e.g., using a current-limited power supply) and check for basic operation and abnormal heating.

Full Functional Test: The ultimate test is to return the board to its original application or test fixture to ensure it performs all functions correctly.

Board Layers: Repairing inner-layer traces on multi-layer boards is extremely difficult and often not feasible.

Component Availability: Finding exact replacements for obsolete or proprietary components can be a major hurdle.

Economic Viability: Weigh the cost of repair time and parts against the cost of a replacement board or module.

Time & Skill: Complex repairs require advanced skills, expensive tools (microscope, rework station), and significant time.

Seek a professional PCB repair service when:

The board has multi-layer damage.

The fault is intermittent or not easily diagnosed.

You lack the specialized tools or micro-soldering skills.

The board is high-value or mission-critical.

Q1: Can you repair a circuit board with a broken line?

A: Yes, trace repair is a common procedure. As described above, a broken trace can be bridged with a small wire. The success depends on the trace's location, size, and accessibility.

Q2: What is the most common reason for circuit board failure?

A: Thermal stress and power surges are leading causes. This manifests as cracked solder joints, failed electrolytic capacitors (from drying out or overheating), and overvoltage damage to semiconductors.

Q3: What tools are essential for basic circuit board repair?

A: A minimum kit includes: a temperature-controlled soldering iron, quality solder and flux, desoldering braid/pump, a multimeter, tweezers, magnification, and isopropyl alcohol for cleaning.

Q4: Is it worth repairing a circuit board?

A: It depends on the board's value, replacement cost, and failure cause. Simple fixes like replacing a cracked connector or a blown fuse are highly worthwhile. For complex IC failures on low-cost boards, replacement is often more economical.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..