The Daily Choice We See on the Production Floor

At our factory in Shenzhen, engineers often ask: “Should I use an SMD or Through Hole component here?” This isn't just a technical question—it's a decision that affects your product's performance, cost, and reliability.

Let’s set aside textbook definitions and look at both technologies from a practical manufacturing perspective.

A Practical Look from the Production Line

SMD (Surface Mount Device): Like Putting a Stamp on an Envelope

-

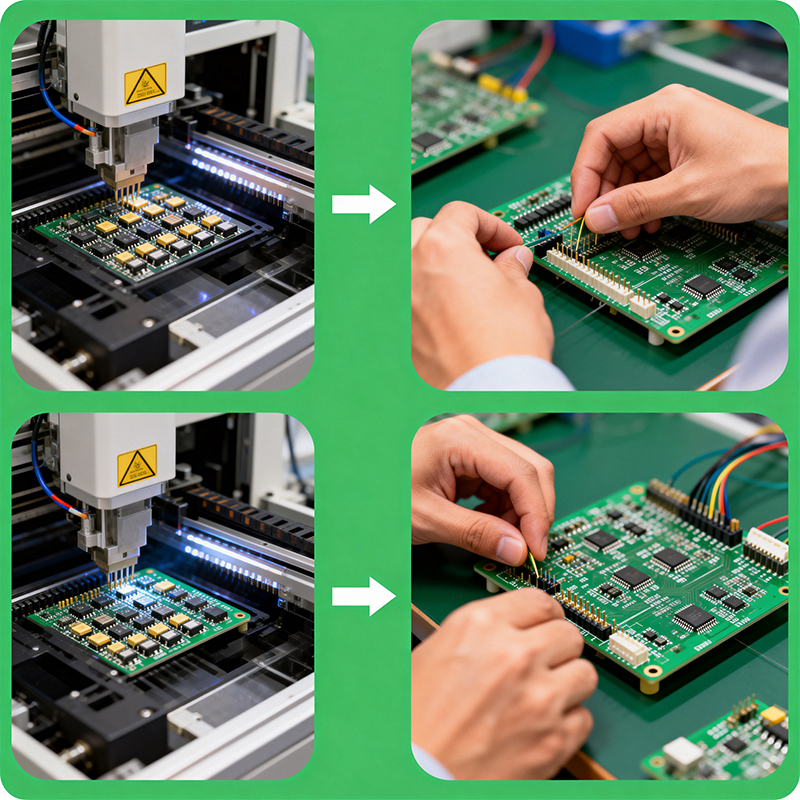

How it's done: Solder paste is printed onto the PCB through a stencil, components are "placed" onto the paste by a machine, then everything goes through a reflow oven.

-

The Good: Perfect for automation. It's fast, consistent, and allows for very small components (think inside a smartphone).

-

Things to Consider: Rework can be trickier, especially for chips like BGAs that solder underneath. It also demands a very flat PCB.

Through Hole: Like Fastening Parts with Screws

-

How it's done: Component leads go through holes in the PCB, then the board's underside is soldered, often by wave soldering or by hand.

-

The Good: Creates a very strong mechanical bond, great for parts under physical stress. Generally simpler to rework or replace.

-

Things to Consider: Often involves more manual or semi-automated steps and takes up more board space.

How to Actually Make the Choice

From our experience at Kaboer, here’s the common decision logic we see:

Lean towards SMD when your product needs:

-

Miniaturization: To be smaller and thinner, like in wearables.

-

High-Frequency Performance: SMD parts have smaller parasitic effects, better for signal integrity.

-

High-Volume Production: Large quantities where automation controls cost.

Consider Through Hole when your product needs:

-

Mechanical Durability: For connectors, switches, or anything that gets plugged, pushed, or pulled often.

-

High Power: Large resistors, transformers—through hole often handles heat better.

-

Easy Serviceability: For industrial or test equipment where easy repair matters.

More often than not, we see a mix of both.

This is the reality for most modern electronics. A mainboard might use SMD for core chips and tiny capacitors, but through hole for power connectors. The key is using the right component in the right place.

Practical Advice for Designers

-

Start with Your BOM: List all components. See which ones are only available in through-hole or only in SMD.

-

Check the Supply Chain: Some older components might only be available in through-hole now.

-

Talk to Your Manufacturer Early: Getting input from the production line during design can reveal small changes that make a big difference.

-

Don't Forget Test & Repair: Think about the product's lifecycle. Will it need servicing? Are test points accessible?

At Kaboer, we handle mixed-technology boards every day. The best designs are usually those that consider manufacturability—understanding what’s possible on the factory floor, then making the optimal choice.

If you're stuck choosing between package types, our advice is simple: start with how the product will be used in the real world, and work backwards from there. A great design not only works on paper but can also be built efficiently and reliably.

Kaboer's Shenzhen factory has deep experience with mixed SMD and Through Hole assembly. We believe understanding manufacturing leads to better design.