Date: 2026-01-05

If you're searching these terms, you're probably wondering: “For the parts on my board, which way should I go?” Especially for things like connectors, big capacitors, or anything that gets plugged and unplugged a lot.

Don't overthink it. In our Shenzhen factory, where we see hundreds of different boards every day, it boils down to one thing: what your thing is supposed to do.

Surface Mount — Like Using Double-Sided Tape

How it works: A machine “spreads” solder paste through a stencil. Another machine uses tiny nozzles to pick and place components (some smaller than a sesame seed) onto the paste. Then, into the “oven” (reflow soldering) it goes.

The Good: Saves space, super fast, very consistent. Think smartphones, earbuds, smartwatches — it’s all SMD.

The Not-So-Good: Parts are stuck to the surface. Reworking or replacing them can be tricky, especially chips with hundreds of hidden solder balls underneath. The board also needs to be pretty flat.

Through Hole — Like Hammering a Nail

How it works: You poke the component’s “legs” (leads) through holes in the PCB. Then you either run it over a “wave” of molten solder or hand-solder it.

The Good: It’s strong! You can pull, push, and plug without worrying about it coming loose. Usually handles heat better too.

The Not-So-Good: Takes up more real estate, more labor (or semi-auto), and isn't great for tiny parts.

You’ll get the idea quickly:

Scenario 1: The Power Jack

Your worry: Users plug and unplug the charger every day. Will the solder pads rip off?

Our advice: Go through hole, no question. Those leads go through the board and anchor it like a nail in a wall. The stress is inside the board, so it can take the abuse.

Scenario 2: The Main Brain Chip (like an MCU)

Your worry: It needs lots of pins, but the board is small and costs matter.

Our advice: Surface mount, definitely. Modern chips come in flat packs (QFP, BGA) with dozens or hundreds of pins. Through-hole isn't even an option here.

Scenario 3: The Big, Heavy Electrolytic Capacitor

Your worry: This board will vibrate in a car or machine. Will the solder joints on this heavy part crack?

Our advice: Lean towards through hole. The leads can absorb stress, and the joints are robust. If you must use a surface-mount version, you'll need special reinforcement.

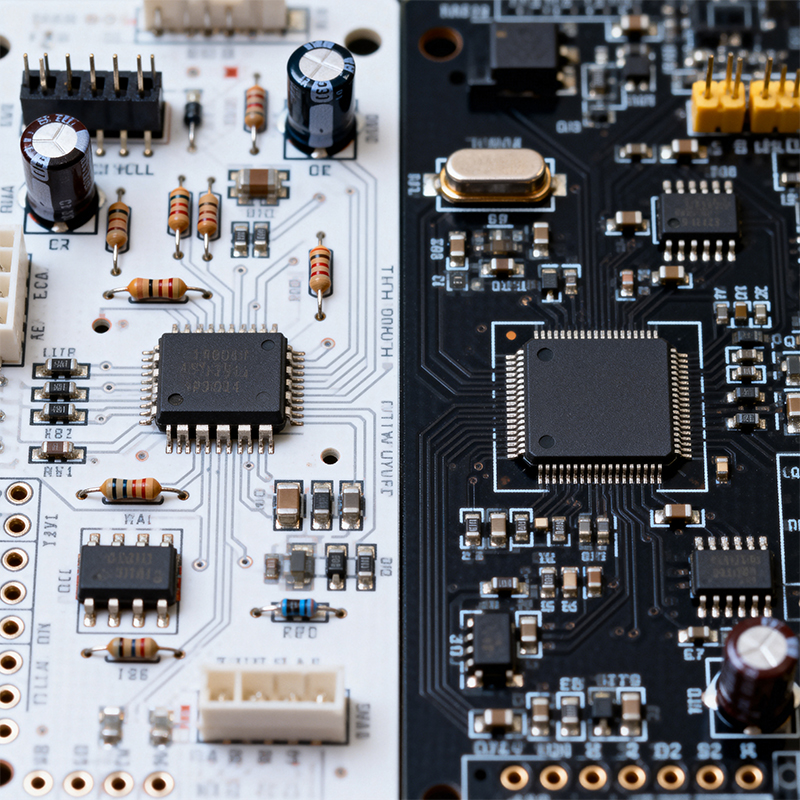

So in reality, most boards are hybrids: the brains and tiny parts (ICs, resistors) are surface mount; the muscle and interfaces (power ports, USB sockets, big inductors, test points) are through hole. One isn't killing the other; they just have different jobs.

Ask “Is it repairable?” first: If you're building industrial gear meant to last a decade in the field, using more through-hole parts means a technician with a simple soldering iron can fix it.

Don't fight the supply chain: Some older or specialized parts might only be available in through-hole versions anymore. Check availability before you finalize the design.

Beware the “shadow effect”: If you mix through-hole on one side and SMD on the other, production gets complex (sometimes requiring two oven passes). Try to group through-hole parts on the same side if possible.

The most important tip: Send your design to your manufacturer early. At Kaboer, we review client files all the time. We might say, “You placed this through-hole inductor 3mm from a surface-mount chip? During wave soldering, the inductor will block the solder, and the chip pins might not solder properly.” A change at the design stage saves a mountain of hassle and cost later.

Choosing between through hole and surface mount isn't a test. There's no single right answer. It's a balancing act based on what your product is (is it going in a phone or a bulldozer?), your budget, and how many you're making.

We hope this plain talk helps make your design more robust and your production smoother.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..