Date: 2026-01-19

Think about your favorite electronic gadget. Now imagine taking it apart. Inside, you’ll find a green (or sometimes black or blue) board that looks like a tiny, intricate city. That’s the Printed Circuit Board, or PCB. It’s the stage where all the electronic components come together to perform.

But not all stages are built the same. If you’re designing or sourcing electronics, knowing your PCB types is like knowing the difference between a Broadway theater, a movie set, and a pop-up street stage. Each serves a different purpose. Let’s walk through the lineup, and you’ll see why one type, the SMT PCB, is the undisputed superstar headlining almost every show today.

First, let’s pay respects to the veteran that started it all.

The Gist: Components have little wire legs (leads) that are poked through holes drilled in the bare board and soldered on the back.

The Analogy: It’s like building furniture with nuts and bolts. You put the bolt through a hole and fasten it tightly on the other side. It’s incredibly strong and hard to shake loose.

Best For: Prototypes where you might need to swap parts by hand, or products that will face serious physical shaking or heat (think some industrial machinery or high-power guitar amps).

The Catch: It’s slow. Drilling all those holes and manually inserting parts isn’t friendly for making 10,000 smartwatches. It also limits how small and packed your circuit can be.

This is the method that changed everything. When people talk about modern electronics manufacturing, this is what they mean.

The Gist: Components are like tiny, flat chips. They’re placed directly onto the surface of the board. A special solder paste holds them in place before everything goes into an oven that melts the paste, making a permanent connection.

The Analogy: Think of applying vinyl decals or using a high-tech sticker machine. It’s precise, fast, and sits flush to the surface.

Why It’s Everywhere: This is the key to miniaturization. No holes needed means components can be smaller and packed tighter. It’s fully automated—machines can place 100,000+ parts per hour with pinpoint accuracy. This makes your phone slim, your smartwatch possible, and keeps costs down for mass production.

The Bottom Line: An SMT PCB is the default choice. It’s not *a* type of board; for modern devices, it’s the type of board. The following categories are really about the board’s structure, which is then built using SMT.

Now, let’s talk about the stage itself. How complex does it need to be?

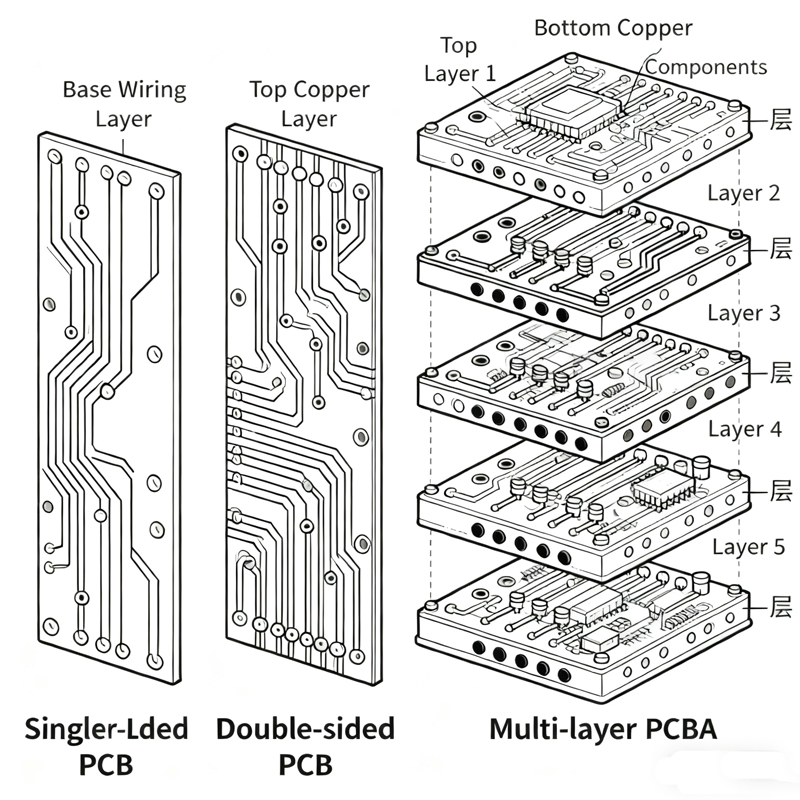

Single-Sided PCBs: The simplest stage.

All the circuitry lives on one side. It’s cheap, easy to make, and perfect for basic electronics like a remote control or a simple power supply.

Double-Sided PCBs: The efficiency upgrade.

Circuits run on both the top and bottom, connected by small metal-lined holes called vias. This doubles the real estate without doubling the board size. It’s the sweet spot for a huge range of consumer gadgets.

Multilayer PCBs: The blockbuster production.

Imagine a club sandwich of conductive layers (4, 6, 8, or even 64!), insulated from each other. This is for complex devices like smartphones, routers, and medical equipment. It allows for incredibly dense, high-speed, and interference-free circuitry. This is where advanced SMT capabilities are non-negotiable, as the components are minuscule and the margin for error is zero.

Finally, what’s the stage made of? Does it need to bend?

Rigid PCBs: Your standard, sturdy board. It’s the workhorse.

Flexible PCBs: Made of a bendable plastic film. They can twist and fold, fitting into crazy spaces like a camera hinge, a wearable device, or a car’s dashboard.

Rigid-Flex PCBs: The clever hybrid. It combines rigid boards (for mounting heavy components) with flexible connectors. This creates a 3D shape that saves space and weight, common in advanced laptops and medical scopes.

You can have a brilliant multilayer, rigid-flex design. But if your manufacturing partner’s SMT line isn’t up to snuff, it’s like handing a Stradivarius violin to a novice.

This is where a partner with deep, in-house expertise stands out. A company like Kaboer, which runs its own PCBA factory in Shenzhen, doesn’t just assemble boards; it masters the SMT process. For you, this means:

They speak the language. You can talk about 0201 components or 0.3mm pitch BGAs, and they get it.

They catch problems before you do. Using tools like real-time solder paste inspection and automated optical inspection is standard for them, saving you from costly field failures.

They navigate the supply chain. Being in Shenzhen gives them a front-row seat to the global component market, which is invaluable for managing cost and availability.

Choosing the right PCB type starts with your vision: How small? How complex? How durable? For over 90% of today’s answers, the path leads directly to SMT PCB technology.

The real magic happens when a clear design meets a manufacturing partner who can execute it flawlessly. It’s the difference between a sketch on a napkin and a product that works, reliably, in the hands of thousands of users. So, know your PCB lineup, but choose your manufacturing partner like you’re casting the lead role—because in many ways, you are.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..