Date: 2026-01-19

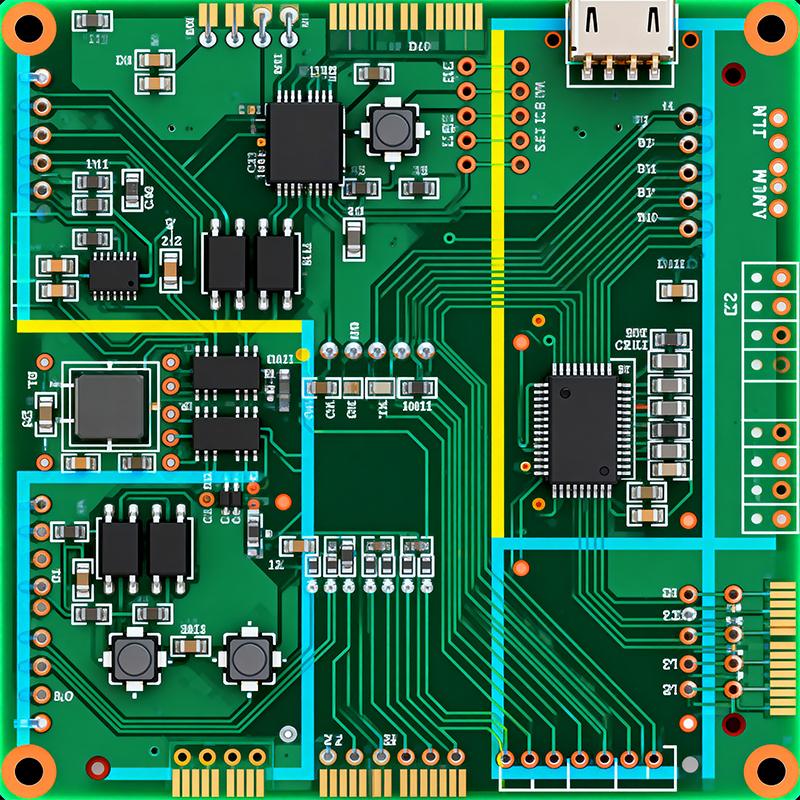

Inside every electronic device, a green circuit board acts as its "skeleton" and "nervous system." Today, the manufacturing of these boards is overwhelmingly centered on a technology called SMT. This article explains, in straightforward terms, what an SMT PCB is and why it is a fundamental cornerstone of modern electronics manufacturing.

SMT stands for Surface Mount Technology. An SMT PCB is a printed circuit board that uses this method to mount electronic components.

A simple analogy can help illustrate the difference:

Traditional Technology (Through-Hole): This is like drilling holes in a board, inserting components with long wire leads through them, and then soldering or fastening them on the other side.

SMT Technology (Surface Mount): This is like applying a special adhesive (solder paste) to the board's surface and then placing flat components with short leads or no leads directly onto it before curing.

This "mounting-on-the-surface" approach is the key reason why electronic products have become smaller and smarter.

SMT has become the absolute standard because it has fundamentally transformed electronics manufacturing. Its primary roles are:

1. Enabling Product Miniaturization and Light Weight

SMT components are typically one-tenth the size and weight of their through-hole counterparts, or even smaller. This has made portable devices like smartphones, Bluetooth earbuds, and smartwatches possible.

2. Increasing Production Efficiency and Consistency

SMT assembly is a highly automated process. High-speed pick-and-place machines can mount tens of thousands, even hundreds of thousands, of components per hour—far surpassing manual speed—while drastically reducing human error and ensuring consistency across production batches.

3. Improving Circuit Performance and Reliability

With shorter electrical paths, SMT components reduce parasitic inductance and capacitance. This makes them better suited for high-frequency, high-speed circuit designs (e.g., 5G, Wi-Fi 6). Furthermore, automated reflow soldering typically creates more uniform and reliable solder joints.

4. Reducing Overall Production Costs

While initial equipment investment is high, SMT allows for higher-density board designs (saving PCB material), and its automation significantly reduces labor costs. For large-scale production, this leads to a substantially lower cost per unit.

5. Supporting More Complex and Integrated Designs

As chip integration advances (e.g., BGA, QFN packages), only precise SMT processes can reliably solder them. SMT is the essential bridge that allows advanced chips to be used in final products.

Understanding its typical workflow clarifies the process:

Solder Paste Printing: A stencil is used to accurately print paste-like solder onto the PCB's contact pads.

Component Placement: Using nozzles, the pick-and-place machine positions various micro-components onto the pasted pads with extreme precision.

Reflow Soldering: The board passes through a reflow oven where the solder paste melts and then solidifies, permanently attaching the components.

Inspection and Testing: Automated Optical Inspection (AOI), X-ray inspection (for hidden joints like BGAs), and functional testing ensure there are no defects like missing, misaligned, or poorly soldered components.

For global electronics manufacturers, partnering with a professional SMT PCB assembler means:

Transforming designs into high-quality products rapidly.

Gaining access to a stable and reliable production supply chain to navigate market fluctuations.

Achieving the optimal balance between cost, quality, and delivery time.

Take Kaboer, a PCBA manufacturer with its own factory in Shenzhen, China, as an example. Their facility is equipped with modern SMT lines capable of handling boards from simple to highly complex. Shenzhen, being a global epicenter for electronics manufacturing, provides companies like Kaboer with a mature industrial ecosystem. This allows them to offer competitive manufacturing solutions to international clients while ensuring transparent communication and efficient process control from engineering support to production.

In summary, SMT PCB technology is the bedrock of modern electronics manufacturing. It is not merely a question of "how to build," but a critical factor that determines the possible form, functionality, and cost-effectiveness of an electronic product. From consumer electronics and automotive systems to medical devices and industrial controls, nearly every modern electronic device relies on this technology. For equipment manufacturers, understanding the value of SMT PCB and choosing a technically proficient, communicative manufacturing partner like Kaboer is a crucial step toward product success.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..