Date: 2025-10-09

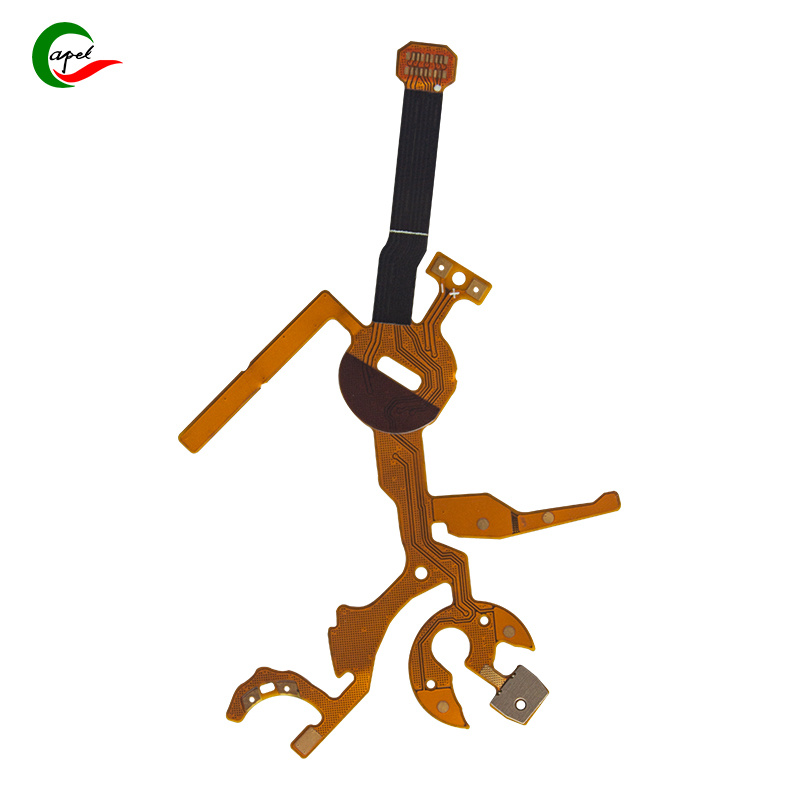

If you're designing anything that bends - from smartwatch sensors to foldable phone hinges - you've probably wondered about flexible PCBs. More importantly, you've likely asked: "Will these floppy circuits actually deliver clean, reliable signals?"

Having designed and tested hundreds of flex PCB implementations across consumer electronics and industrial applications, I can give you the straight answer: Yes, they perform exceptionally well - when you understand how to work with them.

Let me break down what really matters for signal integrity in flexible PCBs, based on real testing and hard lessons learned.

What Really Drives Flexible PCB Signal Performance

I've seen too many engineers blame "the flex PCB" when signals degrade, when the real culprits are almost always these three factors:

1. Copper Quality Isn't Just a Spec Sheet Item

The copper on your flex PCB is the highway for your signals. Not all copper is created equal.

Good copper has 99.9% purity with electro-deposited treatment that creates a smooth, uniform surface. This gives you consistent impedance and minimal signal loss, even when the board is dynamically flexing.

Bad copper has impurities and surface roughness that scatter signals like a bumpy road slows cars. I've measured insertion losses that were 30% higher in budget flex PCBs just due to poor copper quality.

Real example: We tested audio performance in wireless earbuds. The version with high-quality copper maintained clean audio at -95 dB THD+N, while the budget version struggled at -78 dB with audible artifacts during movement.

2. Layout Matters More Than You Think

I can't stress this enough: how you route signals on a flex PCB makes or breaks performance.

The worst mistakes I see:

Acute angle bends that cause impedance discontinuities

Inconsistent trace widths that create reflection points

Poor spacing that leads to crosstalk

The fix? We always use curved traces instead of right angles, maintain minimum 0.2mm trace width for critical signals, and implement proper spacing rules. For a recent foldable phone project, our curved hinge routing maintained 10 Gbps data rates through 200,000 bend cycles.

3. Shielding Isn't Optional - It's Essential

Flex PCBs are thin and often run close to noisy components. Without proper shielding, they become antennas for interference.

We typically use:

Copper shielding layers laminated directly into the stackup

Silver-filled conductive epoxy for critical areas

Selective EMI suppression films for weight-sensitive applications

I learned this lesson the hard way on a medical monitor project. The unshielded flex PCB picked up noise from the power supply, creating false readings. Adding a simple copper shield layer solved it completely.

Where Flexible PCBs Actually Shine

Flexible PCBs aren't just "good enough" - in many cases, they're actually superior:

Moving Systems Beat Rigid Boards Every Time

Think about a foldable phone hinge. A rigid PCB would fracture. Wires would fatigue. But a properly designed flex PCB? It maintains signal integrity through thousands of bends. We've tested hinge flex circuits carrying 12 Gbps display data through 300,000 cycles with less than 0.5 dB additional loss.

Space-Constrained Designs Need the Integration

When you're working with smart rings or medical patches, every millimeter counts. Flex PCBs let you place components optimally with shortest possible signal paths. This often results in better performance than trying to connect multiple rigid boards with cables.

Harsh Environments Favor Flexibility

Vibration kills rigid boards and loosens connectors. I've seen flex PCBs in automotive applications survive vibration tests that destroyed traditional wiring harnesses. The secret? The polyimide substrate naturally dampens vibrations that would crack solder joints on rigid boards.

When You Should Be Concerned

Flexible PCBs have their limits, and it's crucial to recognize them:

Extreme High-Frequency Applications

Above 50 GHz, the dielectric properties of standard polyimide become problematic. The material has higher loss tangent than specialized RF substrates. For satellite and millimeter-wave radar applications, we typically use PTFE-based flex materials or hybrid designs.

Cut-Rate Manufacturing

I've seen "bargain" flex PCBs that should never have left the factory. Poor layer registration, inconsistent copper, and inadequate testing. If your supplier can't provide impedance control data and bend-test results, walk away.

The Reality Check

After years of testing and deployment, here's what I tell every design team:

Flexible PCBs will handle your high-speed data, sensor signals, and power delivery just fine - if you respect their characteristics. The performance is in your hands through good design choices and quality manufacturing.

Don't overthink it. Focus on proper stackup design, work with reputable suppliers, and implement basic shielding. Your flex PCB will likely outperform your expectations.

The biggest mistake I see? Engineers treating flex PCBs like "floppy rigid boards." They're not. They're a different technology that requires different thinking. Master that thinking, and you'll get signal performance that rigid boards can't match in dynamic applications.

Remember: A well-designed flex PCB isn't a compromise - it's often the optimal solution for today's bendable, wearable, and foldable electronics.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..