Date: 2025-10-09

I've been taking apart and testing rigid-flex PCBs since they started appearing in consumer devices. One question I hear constantly from product designers and concerned consumers alike: "Will these flexible sections eventually stretch out and get loose?"

After running thousands of bend tests and analyzing field returns, here's what I can tell you: A well-designed rigid-flex PCB won't get loose in normal use. But I've seen plenty that do - and here's why.

The Engineering Behind Why Good Flex Sections Don't Quit

The flexible parts in quality rigid-flex PCBs are surprisingly durable. Here's what makes them last:

Polyimide Has Incredible Memory

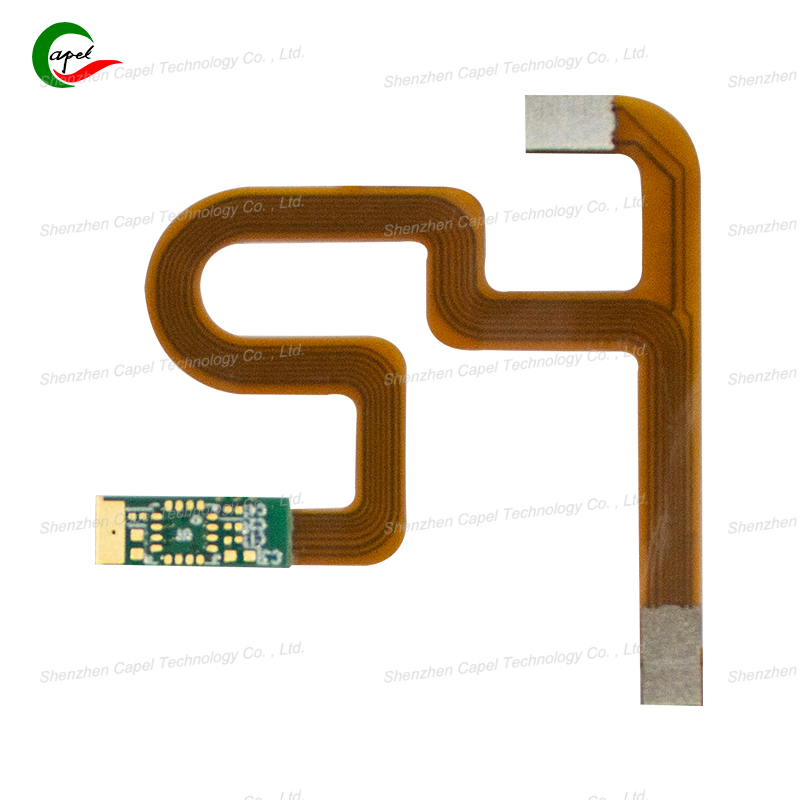

We're not talking about cheap plastic here. The polyimide used in flex circuits is specifically engineered to return to its original shape after bending - think more like a spring than a rubber band.

In our lab, we've tested hinge flex circuits through 200,000+ bend cycles (that's about 5-7 years of normal use for a foldable phone) and measured less than 0.1% permanent deformation. The material essentially "remembers" its flat state.

The Copper Isn't Just Glued On

I've seen cheap flex circuits where the copper peels like old wallpaper. Quality rigid-flex PCBs use laminated copper that becomes part of the material structure. We actually etch the circuit patterns after lamination, so the copper is integral to the substrate rather than just sitting on top.

Reinforcement Where It Matters

Most people don't realize that the "flexible" section often includes strategic stiffeners. We might add thin polyimide or stainless steel layers in areas that need extra support. It's like adding a backbone to a rope - you maintain flexibility while preventing stretching.

When Things Actually Do Go Loose (And Why)

I've definitely seen my share of failed flex circuits. They typically fail for one of these reasons:

Cutting Corners on Materials

The difference between industrial-grade and commercial-grade polyimide is massive. We tested a budget tablet's flex circuit that used thinner, lower-quality polyimide. After just 20,000 cycles, the hinge had developed 1.5mm of slack - enough to make the screen feel wobbly.

Ignoring the Bend Radius

Every flex circuit has a minimum bend radius - usually 3-6 times the thickness. I've seen devices fail because someone decided to make the hinge a millimeter tighter to save space. The result? Stressed copper traces and polyimide that never fully recovers.

Environmental Abuse

Polyimide can handle a lot, but I've seen flex circuits in automotive applications fail when exposed to sustained temperatures above 150°C. The material gets "tired" - technically speaking, the polymer chains start to relax and lose their elasticity.

How to Spot Trouble Before It's Too Late

You don't need fancy equipment to identify a flex circuit going bad:

The wobble test: If your foldable device has more play than it used to, that's often the flex section stretching

The crease check: Permanent creases in the flexible area are like wrinkles in fabric - they indicate the material has been over-stressed

Intermittent issues: If your device works fine when open but glitches during folding, the flex circuit is probably failing

Making Your Flex Circuits Last

From both a design and user perspective, here's what actually works:

Respect the Bend

Don't force devices beyond their natural folding motion. I've seen people twist foldable phones like they're wringing out a towel - that's instant death for any flex circuit.

Mind the Heat

I tell everyone: if it's too hot for your hand, it's too hot for your flex circuits. The dashboard of a car on a summer day can hit 70°C - that won't instantly destroy polyimide, but it will accelerate aging.

Choose Quality

The difference between a $2 and a $4 flex circuit might be the difference between 20,000 and 200,000 bend cycles. I always recommend working with manufacturers who provide full material certifications and bend test data.

The Bottom Line

After examining hundreds of failed and successful flex circuits, here's what matters: quality materials, proper design, and reasonable use. A well-engineered rigid-flex PCB in a properly designed device will outlive most other components.

The flexible sections won't get loose under normal conditions - the physics simply don't support that happening. But like any engineered component, they have limits. Push beyond those limits, and yes, you'll eventually have problems.

The good news? Most major manufacturers have learned these lessons the hard way. The rigid-flex PCBs in today's foldables and laptops are significantly more durable than what we saw just three years ago.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..