Date: 2026-01-16

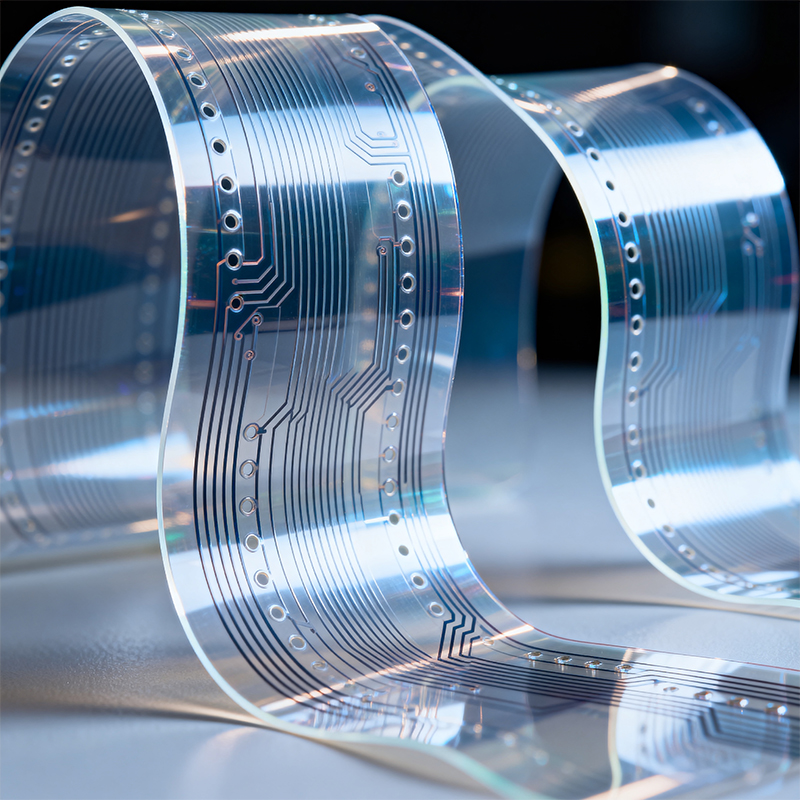

You might be looking for a solution to make circuits "disappear" inside your device. Whether it's for cool LED lighting effects, unique industrial design, or certain functions that must transmit light, traditional green or black circuit boards just won't work. That's when "transparent circuit boards" become an exciting yet confusing option—they sound like future tech, but also raise concerns about cost, reliability, and manufacturing difficulty.

Let's clarify what transparent circuit boards really are and whether they're right for your next project.

First, let's be clear: transparent circuit boards aren't just regular boards with the green solder mask removed. That would only expose the copper traces, which aren't transparent at all. Real transparent circuit boards use completely different material systems. There are three main technical approaches:

This is like "drawing" circuits on a piece of glass. The most common transparent conductive material is ITO (Indium Tin Oxide)—the same material on your smartphone touchscreen. Circuits are patterned onto glass through photolithography or laser etching.

Advantages:

Extremely high transparency (can exceed 90%)

Perfectly flat surface

Good stability and high-temperature resistance

Disadvantages:

Glass is fragile and requires careful handling

Multilayer boards are difficult or impossible

Higher cost

Typical Applications: Integrated lighting for high-end display cases, backlit automotive console panels, special instrument windows for laboratories.

Using transparent plastics like PMMA (acrylic) or PC (polycarbonate) as substrates, with circuits "printed" using silver nanowires, conductive polymers, or special transparent conductive inks.

Advantages:

Lightweight with some flexibility

Can be formed into curved shapes

Relatively controllable cost

Disadvantages:

Poor heat resistance requires low-temperature soldering

Potential aging issues with long-term use

Conductivity inferior to traditional copper traces

Typical Applications: Smart home control panels, decorative circuits for wearables, interactive display installations.

This is the most practical and common approach. Use transparent materials only in areas that need transparency, while the rest uses traditional PCB technology, then combine both.

Advantages:

Balances functionality, cost, and reliability

Leverages mature PCB processes

Offers greater design freedom

Disadvantages:

Visible joints between materials may affect aesthetics

Requires precise assembly techniques

Typical Applications: Instrument panels with transparent viewing windows, switch panels with integrated indicator lights.

Before diving into technical details, clarify your real needs:

Is transparency a functional requirement or an aesthetic one?

If functional (e.g., must see through for observation), transparency is a hard requirement

If aesthetic (e.g., making circuits part of the design), there may be many alternatives

What kind of electrical signals need to be carried?

Just simple power and low-speed signals? Transparent materials might suffice

Need to transmit high-speed data or RF signals? This could be challenging

What's the operating environment?

Indoor, mild conditions? Most materials can handle this

High temperature, humidity, or outdoor use? Material and process selection requires caution

What's your expected production volume?

Small batch prototypes? Consider manual fabrication or outsourcing

Mass production? Must evaluate supply chain and costs carefully

What's your budget?

Transparent circuit boards typically cost 3-10 times more than traditional PCBs. Does this fit your project budget?

Transparent conductive materials have much higher resistivity than copper. ITO typically has sheet resistance of 10-100 ohms/square, while copper foil's is negligible. This means:

Not suitable for high-current applications

Significant signal attenuation over longer distances

Limited high-frequency performance

Solutions:

Keep transparent trace lengths as short as possible

Increase trace width to reduce resistance

Use fine copper wires embedded in transparent layers for critical sections (hybrid design)

Soldering components onto glass or plastic requires special processes:

For glass substrates:

Use low-temperature solder (like indium-based alloys)

Employ conductive adhesives

May need special fixtures to prevent thermal stress cracking

For plastic substrates:

Strictly control soldering temperature and duration

Consider using connectors instead of direct soldering

May require pre-embedded solder pads

Transparent materials can be more fragile or prone to aging:

Glass is impact-sensitive

Plastics are susceptible to scratching and UV damage

Transparent conductive layers may degrade from bending or moisture

Solutions:

Add protective coatings (like hard coatings)

Incorporate mechanical support in the design

Conduct rigorous environmental testing

Transparent circuit boards are harder to test and repair:

Traditional test probes may slip or damage surfaces

Heating during repair may affect transparent materials

Fault points are harder to locate visually

Recommendations:

Design in additional test points

Prepare specialized test fixtures

Consider modular design for easier replacement

Understanding cost breakdown can help optimize your design:

Material Costs (40-60%):

Specialty glass or optical-grade plastics

ITO targets or specialty conductive inks

Specialized adhesives and protective coatings

Processing Costs (30-50%):

Cleanroom environment requirements

Precision laser processing or photolithography equipment

Special lamination and curing processes

Equipment amortization for low volumes

Design & Engineering Costs (10-20%):

Special DFM (Design for Manufacturability) analysis

Process development and validation

Test program development

Cost Reduction Possibilities:

Reduce transparent area size

Use hybrid designs

Choose more mature technology paths

Collaborate early with suppliers to optimize processes

If your main goal is aesthetic effect, consider these alternatives:

1. Semi-Transparent Effects

Traditional PCBs with light-colored or semi-transparent solder mask, combined with careful layout, can create a "hint of circuitry" aesthetic, costing only 10-20% more.

2. Selective Windows

Create openings in specific areas of traditional PCBs (like around LEDs) to expose the copper below, then cover with transparent or translucent housings for similar effects.

3. 3D Printed Circuits

For some non-critical applications, 3D printed transparent structures with embedded conductive traces offer another innovative approach.

We've handled some transparent circuit board projects and have gained practical insights:

About Technology Selection:

For most clients, we typically recommend starting with "hybrid designs." For example, a smart mirror project only needed transparent circuits along the edges for LED drivers. We suggested using traditional PCB for the main body and only glass substrates for the lighting sections, reducing costs by 60%.

About Supplier Management:

The supply chain for transparent circuit boards is completely different from traditional PCBs. We recommend clients audit at least two material suppliers and ensure they have stable quality control and backup sources.

About Design Iterations:

Transparent circuit board designs often require more iterations. One client's project went through 7 design revisions from concept to mass production. Allowing sufficient development time and budget is crucial.

About Quality Control:

We've established specialized inspection standards for transparent boards, including light transmittance tests, conductive layer adhesion tests, and targeted environmental reliability tests. This upfront investment prevents batch issues later.

If you decide to proceed, we recommend these steps:

Proof of Concept Phase (1-2 weeks)

Create the simplest functional sample

Test basic electrical and optical performance

Assess process feasibility

Design Optimization Phase (2-4 weeks)

Discuss design options in depth with manufacturers

Create prototypes close to the final version

Conduct comprehensive reliability testing

Small Batch Trial Production (3-6 weeks)

Produce 50-100 trial units

Verify production process stability

Gather real-world usage feedback

Mass Production Preparation (4-8 weeks)

Optimize production processes

Establish quality control systems

Prepare for volume manufacturing

Transparent circuit boards represent a fascinating technological field that can make products stand out. But they're not a universal solution—they're better suited for products where transparency is core to the value proposition, not just for "looking cool."

If you're considering this direction, the most important things are an open mind and a practical attitude. Start by clarifying requirements, understand the pros and cons of various options, and validate feasibility step by step. Sometimes, the simplest solution turns out to be the most effective.

Whether your project ultimately uses transparent circuit boards or not, understanding this technology's possibilities and limitations will make you a better product designer and decision-maker.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..