Date: 2026-01-16

When you search for "bare circuit board," you might be looking for a PCB supplier for a new product or trying to understand why the same design gets wildly different quotes from different factories. Perhaps you're selecting a PCB supplier for a critical project and want to know how to avoid pitfalls that affect yield. Whatever your specific need, understanding the basics of bare boards will help you make smarter decisions throughout the PCBA process.

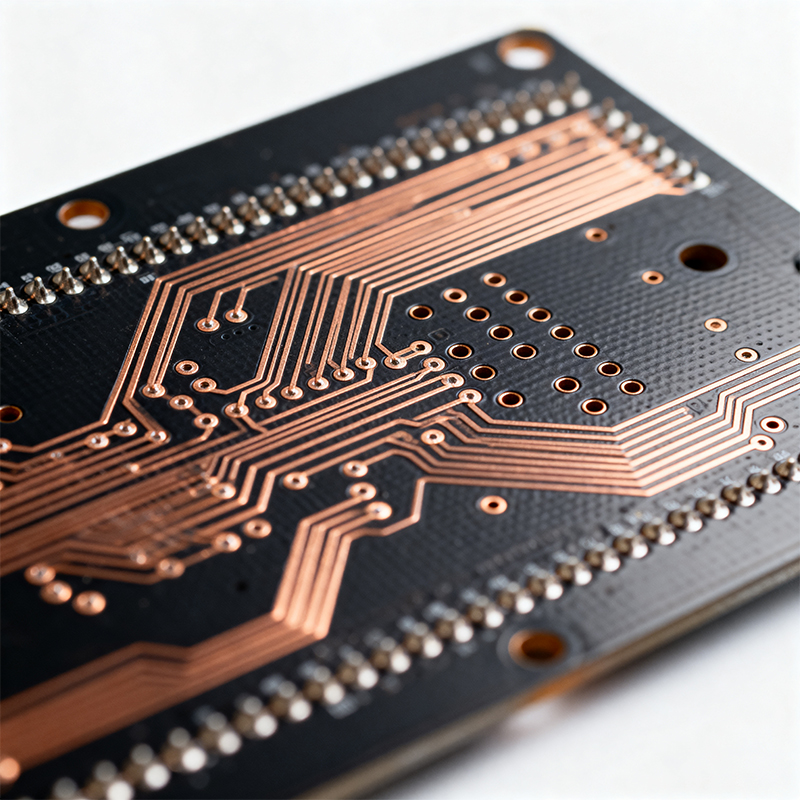

Simply put, a bare board is a printed circuit board that has completed all circuit fabrication but hasn't had any electronic components installed yet. Think of it like a wall before painting—the structure and electrical conduits are in place, but switches, outlets, and lights haven't been installed.

A complete bare board typically includes:

Insulating substrate (most commonly FR-4)

Circuit patterns formed by copper foil

Drilled holes (for component leads and interlayer connections)

Surface finish (protects copper and ensures solderability)

Silkscreen markings (component placement and orientation)

Solder mask (prevents solder shorts)

Design Validation Phase:

When a factory receives your Gerber files, the first step is a DFM (Design for Manufacturability) check. A responsible manufacturer will check if trace widths and spacings match their process capabilities, if pad designs are reasonable, if drill holes are too close to board edges, etc. Solving problems at this stage costs far less than discovering them on the production line.

Material Selection and Preparation:

Just as baking different pastries requires different flours, different applications need different substrates:

Standard consumer electronics typically use basic FR-4

High-frequency applications need low-loss materials (like Rogers, Taconic)

High-reliability products may require high-Tg (glass transition temperature) materials

Flexible circuits use polyimide film

Pattern Transfer Process:

This is the key step that "prints" the circuits. Factories use photolithography to transfer your circuit design onto copper-clad laminate. The process is somewhat like old film photography—through exposure and development, the design pattern is transferred to photosensitive material, then unwanted copper is etched away.

Drilling and Hole Metallization:

After drilling those tiny holes (some finer than a human hair), copper needs to be deposited on the hole walls to create electrical connections between layers. The quality of this step directly affects multilayer board reliability. Rough hole walls or insufficient copper thickness can lead to future failures.

Surface Finish Selection:

Different surface finishes suit different applications:

HASL: Lowest cost, but limited flatness

ENIG: Flat surface, good for fine-pitch components

Immersion Silver: Good electrical performance but may oxidize over time

OSP: Most environmentally friendly but has limited shelf life

Quality Testing and Verification:

Every bare board must be tested before shipping. Basic electrical testing ensures no opens or shorts. For complex or high-reliability products, additional tests like impedance testing or thermal shock testing may be needed.

Single-sided: Most basic type, only one copper layer, lowest cost

Double-sided: Copper on both sides, connected by vias, most common choice

Multilayer: Four layers or more, for complex circuit designs

Rigid boards: Most common type, maintain fixed shape

Flexible boards: Can bend, for space-constrained or wearable devices

Rigid-flex boards: Part rigid, part flexible, combining both advantages

Heavy copper boards: For high-current applications

High-frequency boards: For RF and high-speed digital circuits

Metal-core boards: For applications with extreme heat dissipation needs

Impedance control accuracy: Critical for high-speed signals, typically requiring ±10% control

Insulation resistance: Ensures no leakage between different nets

Voltage withstand capability: Prevents high-voltage breakdown

Dimensional accuracy: Especially hole positions and board edge accuracy, affecting assembly

Surface flatness: Affects soldering of fine-pitch components

Hole wall quality: Copper thickness and uniformity in holes

Thermal shock resistance: Ability to withstand reflow temperature changes

Chemical resistance: Resistance to flux and cleaner erosion

Peel strength: Bond strength between copper foil and substrate

A professional bare board specification should include:

Material Specifications:

Substrate type, brand, and model

Copper thickness (typically in ounces, e.g., 1oz = 35μm)

Solder mask and silkscreen ink types

Process Parameters:

Minimum trace width/clearance

Minimum hole size and annular ring

Layer-to-layer registration tolerance

Board thickness and tolerance

Surface Finish:

Finish type and thickness

Storage conditions and shelf life

Testing Standards:

Electrical test coverage (100% or sampling)

IPC standard class adopted (Class 1, 2, or 3)

Special test requirements (like impedance testing)

Answer: Price differences may come from:

Material quality differences (imported vs. domestic, well-known brands vs. generic)

Different process capabilities (affecting yield and final quality)

Different testing standard strictness

Factory operating costs and management efficiency

Class 1: General consumer electronics, allows more cosmetic imperfections

Class 2: Standard for most industrial, automotive, and communications equipment

Class 3: High-reliability products like medical, aerospace, military applications

This depends on the factory's focus. Prototype-focused factories may accept small orders of 5-10 pieces, while mass-production-focused factories may require at least 100 pieces or more. Some factories charge engineering fees or premiums for small orders.

Standard lead times are typically:

Single/double-sided: 5-10 working days

4-layer: 7-14 working days

Complex multilayer: 2-4 weeks

Expedited services are usually possible but increase costs and may affect quality

Review the factory's actual process capability chart

Request a facility tour or at least provide videos/photos

Ask what types of boards they specialize in producing

Understand their quality control processes

Ask about defective product handling procedures

Review testing equipment and personnel qualifications

Is initial communication professional and timely?

Do they proactively ask questions or suggest improvements?

Are their quotations detailed and transparent?

If possible, place a small sample order first

Check the sample's process details

Test key performance parameters

Choose standard materials when performance requirements permit

Avoid unnecessary special processes

Consider panel utilization to reduce material waste

Plan order quantities reasonably to balance MOQ and inventory

Choose standard lead times over expedited ones

Consider establishing long-term relationships with factories for better pricing

Choose appropriate test coverage based on product importance

For mature products, consider sampling rather than 100% testing

Discuss test cost optimization options with suppliers

More environmentally friendly halogen-free materials

Higher performance high-frequency materials

Better thermal conductivity materials

Finer trace widths and clearances (moving below 30μm)

More advanced drilling technologies (like laser drilling)

More environmentally friendly surface finishes

More automated inspection equipment

Data-driven process optimization

More traceable production processes

Involve suppliers early in the design: Consult on manufacturability suggestions before finishing layout to avoid many subsequent issues

Clarify your priorities: Is cost, quality, or lead time most important? Different priorities lead to different choices

Build long-term relationships: Establishing stable cooperation with trusted suppliers often brings better overall benefits than constantly searching for the lowest-priced supplier

Keep learning: PCB technology continues to evolve; stay informed about new technologies, materials, and processes

While bare boards are just one component of electronic products, they carry all electrical connections and form the foundation of product reliability. Investing time in understanding bare boards will pay off at every stage of product development.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..