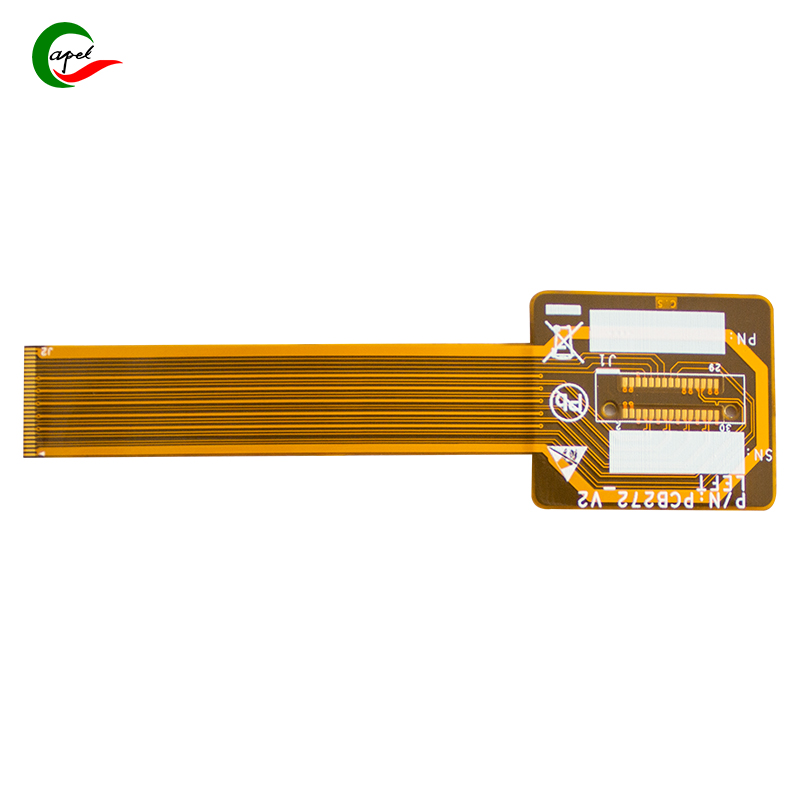

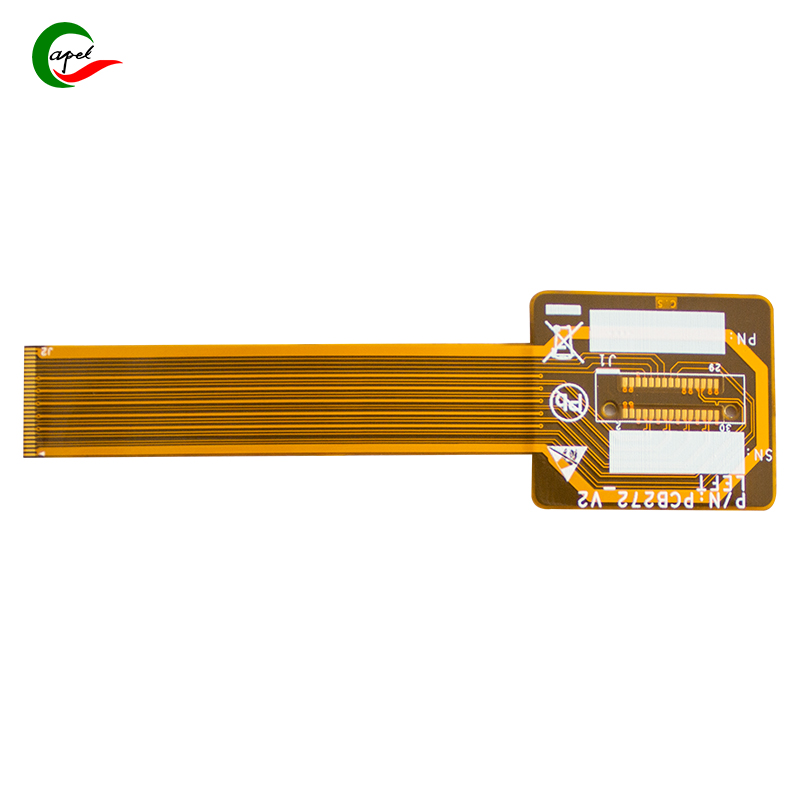

What Is a Flexible Circuit Board? A Clear Breakdown of Its Uses, Materials, Manufacturing & Cost

Date: 2025-09-13

When you think of circuit boards, you probably picture that stiff green board inside a remote control—but flexible circuit boards (FPC for short) are a whole different “style.” They can bend, fold, and fit into spaces smaller than your fingernail, and without them, gadgets we can’t live without—like foldable phones and wireless earbuds—wouldn’t exist.

Below, we’ll break down flexible circuit boards in plain language: what they do, what they’re made of, how they’re produced, and how much they cost. No engineering background required.

At its core, a flexible circuit board still “connects parts and transmits signals”—but it shines in scenarios where rigid circuit boards fail. Think of it as a “versatile flexible bridge” for electronics:

-

Fits into tiny spaces: The inside of a wireless earbud, the edge of a smartwatch dial, or the telescoping part of a camera lens—these spots are too small for rigid boards to “stand.” But flexible circuit boards, thin as a sheet of paper, can wrap around components or tuck into tight gaps. They also replace messy wires, letting gadgets stay small and sleek.

-

Handles repeated movement: A foldable phone gets folded hundreds of times a day—if the circuit board in the hinge were rigid, it would snap instantly. Flexible circuit boards can bend 10,000+ times without breaking, keeping both screens connected. Fitness trackers also rely on them to stay connected as your wrist moves.

-

Cuts down on weight: They’re 70% lighter than rigid circuit boards—a big deal for devices that “fear heaviness,” like drones and smartwatches. Every gram saved improves 手感 (hand feel) and even extends battery life a little.

-

Withstands small knocks: Old devices had fragile wires that broke if dropped. Flexible circuit boards are tough and resilient—even if you accidentally drop your earbuds, the internal circuits are unlikely to fail.

The “superpower” of flexible circuit boards lies in three key layers—remove any one, and it won’t work:

-

Base layer (Polyimide/PI): This is its “flexible skeleton.” It looks like thin plastic, but it’s surprisingly durable. Think of it as “electronic tape”—thin, flexible, and able to fold over 10,000 times. It also resists high temperatures (up to 260°C/500°F), so it won’t melt even when your phone heats up while charging.

-

Conductive layer (Copper foil): This acts as the circuit board’s “invisible wires,” stuck to the polyimide to carry electricity and signals. To keep the board flexible, the copper is ultra-thin—some as thin as 0.01mm (thinner than a human hair!). Only high-power devices (like car parts) use thicker copper foil.

-

Protective layer (Coverlay): A clear, thin film that sticks to the copper foil to “protect it.” It prevents scratches, rust, and accidental contact between the copper and other parts (which would cause a short circuit and break the device). Without this layer, a single speck of dust could ruin the entire circuit.

Flexible circuit boards are trickier to make than rigid ones—they need extra precision to stay thin and flexible. But the core process boils down to 4 simple steps:

-

Design & template printing: Engineers use software to draw the circuit layout (where the copper “wires” go and which parts attach where). They then print this design onto a “photographic film”—like a transparent stencil for the copper.

-

Coating & UV exposure: The polyimide base is coated with a light-sensitive chemical called “photoresist.” The photographic film is laid on top, and the board is exposed to UV light. This hardens the photoresist in areas where copper needs to stay, while leaving it soft where copper should be removed.

-

Etching & protective covering: The board is dipped in a chemical solution that “eats away” the soft photoresist and the copper underneath. What’s left? The exact copper circuit from the design. Next, a coverlay is added and heated to stick firmly to the polyimide, protecting the copper.

-

Cutting & testing: The board is cut into its final shape—like a small strip for earbuds or a curved piece for a phone hinge. Machines then test it for broken wires or short circuits. Only passing boards are sent to factories to have components soldered on.

Flexible circuit boards are pricier than rigid ones, but the cost varies based on three key factors:

-

Size & complexity: Small, simple boards (like those in earbuds) cost $1–$5 each when ordered in bulk (1,000+ units). Complex ones—like the multi-layered boards in foldable phone hinges—can cost $10–$30 each, as they use more copper and require precise cutting.

-

Order quantity: Need 10 prototypes for a new gadget? You’ll pay $10–$50 per board (factories charge setup fees for small batches). But order 10,000 units for mass production, and the price drops to $2–$8 each—setup costs are spread out across more units.

-

Material quality & testing needs: Basic materials are cheap, but high-temperature polyimide (for car parts) or thick copper (for high-power devices) increases costs by 30%–60%. Medical devices use even more expensive flexible boards—they require strict testing, sometimes doubling the base price.

Flexible circuit boards may be thin, but they’re the “heart” of small, sophisticated gadgets. Without them, foldable phones would break after a few folds, and wireless earbuds couldn’t fit in your ear. Their materials make them flexible yet tough; their precise manufacturing ensures they work reliably; and while they cost more than rigid boards, the better user experience they deliver is well worth it. Next time you fold your phone or put on your wireless earbuds, remember: that tiny flexible board inside is what makes it all possible.