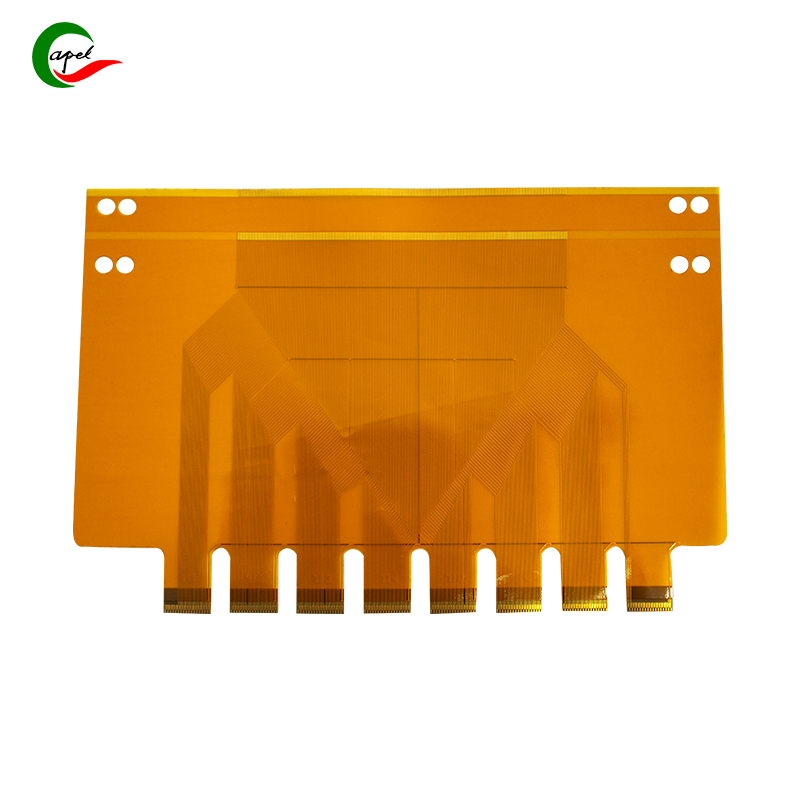

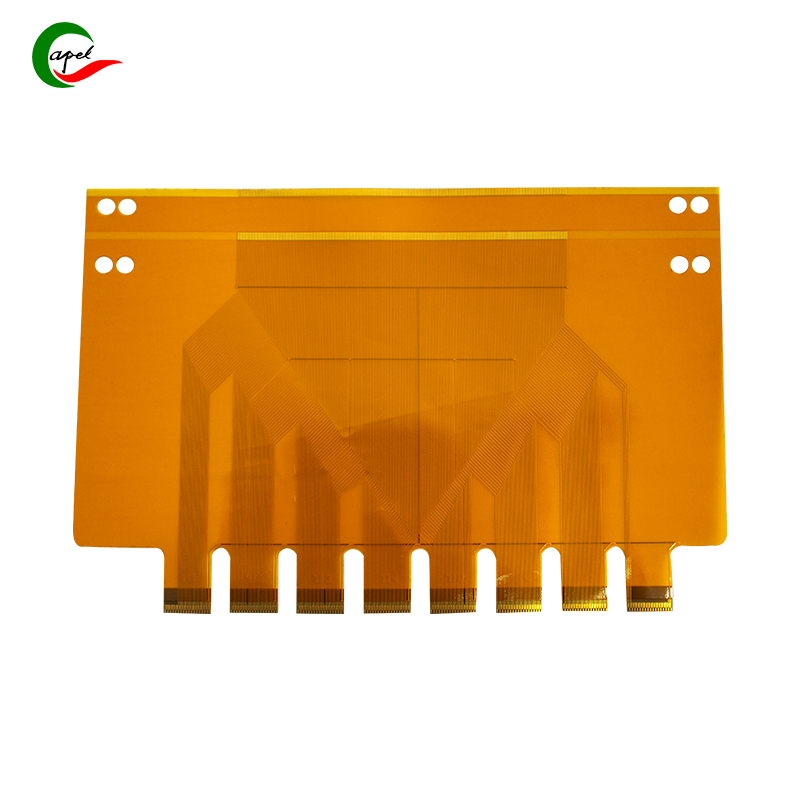

Capel Flexible PCB: Craft Flexible Solutions That Bring Your Gadget Designs to Life

Date: 2025-09-13

Every great gadget starts with a design that pushes boundaries—whether it’s a sleeker wearable, a more durable industrial sensor, or a foldable device that feels natural to use. But turning that vision into reality often hits a wall: finding a flexible PCB that’s tough enough, precise enough, and ready when you need it.

At Capel, we’ve spent 16 years focusing on one thing: making flexible PCBs that don’t just fit your design—they elevate it. This isn’t about selling components; it’s about partnering with you to turn your ideas into tangible, reliable products.

A flexible PCB only matters if it holds up to how people actually use your device—bending, moving, and enduring daily wear. We design ours to last:

-

Premium materials you can trust: We use high-grade polyimide (PI) that handles 10,000+ bends without cracking, paired with ultra-thin yet strong copper foil (as thin as 0.01mm) that stays conductive even after repeated flexing. Every material is chosen for long-term reliability, not just short-term cost savings.

-

Robust protection for every scenario: Each board gets a thick, durable coverlay—no flimsy films here—to shield copper from scratches, moisture, and dust. Whether your device lives in a sweaty wristband, a dusty workshop, or a compact earbud, the PCB stays protected.

-

Rigorous testing for consistency: Every batch goes through checks for flexibility, conductivity, and heat resistance. We don’t ship a board unless it meets our standards—so you get the same reliable performance across every unit.

Your gadget is unique, so your flexible PCB should be too. We start with your specs, not ours:

-

Any shape, any size: Need a tiny, narrow strip for a wireless earbud? A wide, curved board for a foldable display? A multi-layer flex that fits into a tight car sensor? We cut, shape, and layer to match your design’s exact dimensions—no compromising on how your device should look or work.

-

Adapted to your environment: Building a medical device that needs biocompatible materials? A drone part that withstands extreme temperatures? We adjust materials (like heat-resistant PI for 260°C+ use) to fit where your device will operate.

-

True flexibility, no compromises: Our boards bend exactly how your design needs—tight radii, repeated folds, whatever you require. No “semi-flex” limitations that force you to rethink your device’s movement.

We know your timeline is tight—launch dates, prototype deadlines, and production schedules don’t wait. Our process is built for speed:

-

Fast turnarounds, no corners cut: Get prototypes in 5 days and mass production in 10 days (for most orders). We keep key materials in stock, so you don’t wait weeks for PI or copper to arrive.

-

Transparent timelines from day one: We give you a realistic delivery date upfront, and we stick to it. No last-minute delays or vague updates—you’ll always know when your PCBs will be ready.

-

Free pre-production design checks: Our engineers review your Gerber files within 24 hours to spot issues (like a bend radius that’s too tight) before production starts. Fixing small problems early saves you time, money, and frustration later.

You shouldn’t have to explain technical details to get the right PCB. Our team has decades of hands-on experience with flexible circuits, so we understand your challenges:

-

We listen first: Tell us about your design goals, pain points, and what your device needs to do. We’ll help you pick the right materials, layers, and specs—no pushing unnecessary add-ons.

-

A dedicated point of contact: You’ll work with one person who knows your project inside out. They’ll update you on progress, answer questions in plain language, and solve issues fast—no chasing multiple reps.

Your gadget deserves a flexible PCB that’s as innovative as your idea. At Capel, we don’t just make boards—we make sure your device works as well as you imagined, when you need it.

Contact us today for a free quote and design review. Let’s build the flexible solution that brings your gadget to life.