If you’ve used a foldable phone or wireless earbuds, you’ve relied on a tiny yet critical component you’ll never see: a flexible PCB connector. It’s what ensures smooth transmission of electricity and signals—even when the device bends, twists, or fits into tight spaces. Without it, a flexible printed circuit (FPC) is just a sheet of plastic and copper; with it, your favorite bendable devices can actually function as intended.

Below, we’ll break down what a flexible PCB connector is, how it works, why it matters, and what makes a quality one—no complex jargon, just clear explanations.

Think of a flexible PCB connector as a "bridge" between a flexible circuit board and other device components—such as screens, batteries, or sensors. Unlike soldered joints (common on rigid PCBs, which easily crack when bent), these connectors are specifically designed to handle movement.

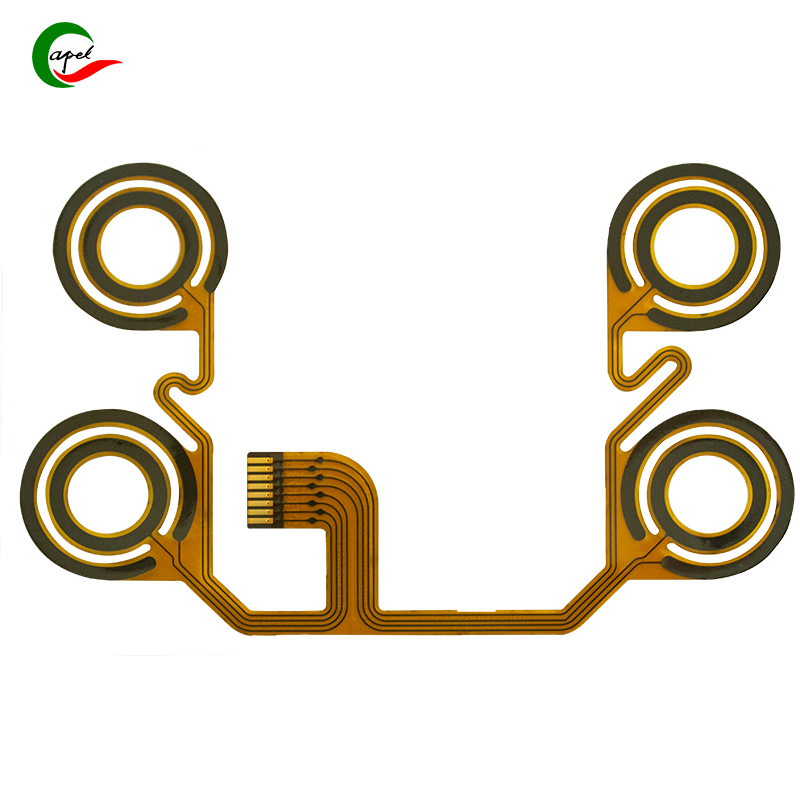

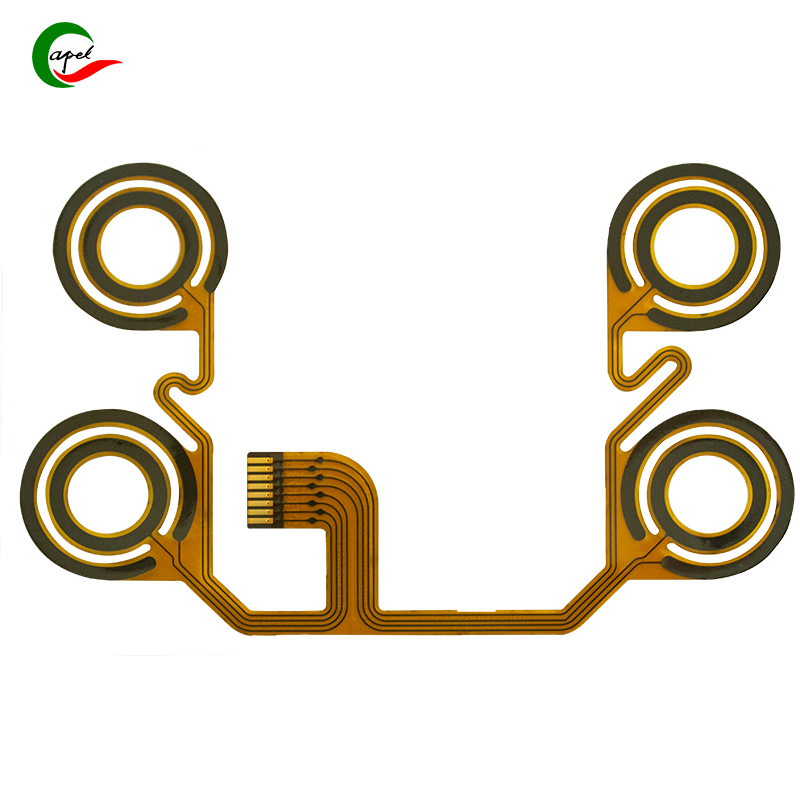

They are typically small—some no larger than a grain of rice—and made primarily from two materials:

-

Metal contacts: Used to transmit electricity and signals (usually copper alloy, chosen for its durability and conductivity).

-

Heat-resistant plastic housing: Holds the metal contacts in place, protects them from damage, and allows the connector to bend without breaking as the device moves.

Its core purpose? To maintain a stable connection, even when the flexible circuit board moves with the device.

The design of a flexible PCB connector balances two needs: maintaining a secure connection and adapting to bending. The principle is straightforward:

-

"Gripping" the flexible PCB: Most connectors use tiny metal pins or flat contacts that press firmly against the copper pads on the flexible PCB. This creates a tight electrical connection without the need for soldering (though some high-power devices add soldering for extra stability).

-

Flexing with the device: The plastic housing is not rigid—it can bend slightly along with the flexible PCB. This means it won’t crack or loosen when the device folds (like the hinge of a foldable phone) or twists (like a smartwatch on your wrist).

-

Withstanding daily wear: The housing shields the metal contacts from dust, moisture, and scratches. Whether your earbuds get sweaty or your fitness tracker collects dirt, the connector stays protected—and the connection remains stable.

Reliable bendable devices simply can’t exist without flexible PCB connectors. Their importance lies in three key areas:

-

Uninterrupted connection during movement: A foldable phone may bend hundreds of times a day. A soldered joint would break within days, but a flexible PCB connector maintains a steady link—ensuring your screen doesn’t suddenly go black and your touch controls keep working when you use the device.

-

Fitting into tight spaces: Devices like wireless earbuds or smartwatch sensors have barely any room for bulky components. These connectors are compact enough to fit into narrow gaps, where rigid connectors (or messy wires) would never work.

-

Simplifying repairs: If a flexible PCB needs replacement (e.g., due to a faulty earbud component), technicians can simply pull out the old board and plug in a new one via the connector—no desoldering required (which risks damaging other parts of the device).

Not all flexible PCB connectors are equally reliable. A good one must have three key traits:

-

Durability: It should withstand over 10,000 bends without losing contact. Cheap connectors may work for a few weeks but will loosen or fail when you need the device most.

-

Stable conductivity: The metal contacts should not rust or lose their ability to transmit signals over time. Quality connectors usually use copper alloy contacts—they resist corrosion and maintain consistent performance long-term.

-

Proper clamping force: It needs to grip the flexible PCB tightly enough to stay connected, but not so tightly that it tears the delicate PCB when removal is needed. A well-designed connector balances "firmness" and "gentleness."

Flexible PCB connectors are small, unnoticeable, and easy to overlook. But without them, your foldable phone, wireless earbuds, and smartwatches wouldn’t work. Even the tiniest components play a vital role in ensuring high-quality devices operate as they should.