Date: 2025-10-23

I'll never forget testing our first 28GHz prototype - the signal losses were so bad we thought our equipment was broken. After days of troubleshooting, we discovered the rigid PCB materials were killing our performance. That frustrating experience started our journey into flexible PCB solutions for high-frequency applications.

The Reality of High-Frequency Signal Challenges

At millimeter-wave frequencies, traditional PCB materials behave like trying to run through mud. We measured one 5G module losing 0.8dB per centimeter at 28GHz - catastrophic for compact devices.

The impedance stability issues were equally troubling. Real-world thermal cycling caused impedance shifts up to ±12% in rigid boards, far beyond the acceptable ±5% margin.

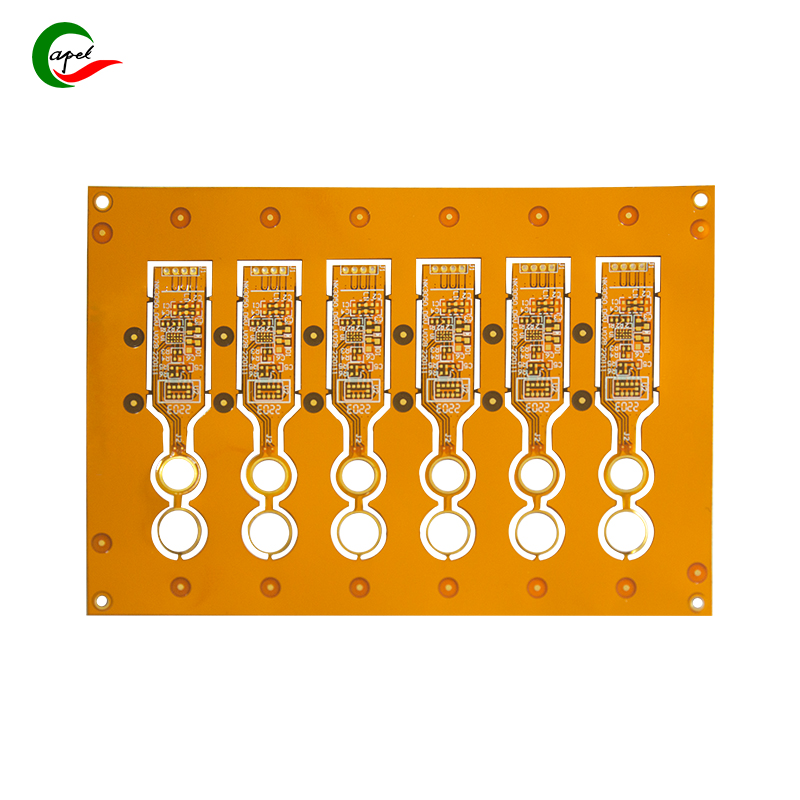

Why Flexible PCBs Became Our Solution

The material breakthrough came when we tested LCP-based flexible circuits. The difference was night and day - we saw 60-70% lower signal loss compared to FR-4 at 28GHz frequencies.

But the real advantage emerged during environmental testing. The natural flexibility of these materials maintained impedance stability within ±3% through thermal cycling and mechanical stress.

Practical Implementation Insights

Through multiple 5G and radar projects, we've developed some key practices:

Material selection is critical. LCP works best above 24GHz, while fluorinated PI handles 1-24GHz applications well. We avoid standard PI for critical high-frequency paths.

Design techniques matter. We use EM simulation to optimize trace geometry, replace sharp corners with gradual curves, and maintain proper spacing between signal types.

Manufacturing precision is non-negotiable. Laser processing ensures consistent traces, while controlled soldering protects sensitive materials.

Real-World Results

The performance improvements have been substantial:

65% reduction in signal loss for 5G smartphones

40% better EMI performance in radar systems

25% improvement in detection accuracy for automotive radar

One automotive radar project achieved these gains while reducing module size by 30%.

The Bottom Line

Flexible PCBs have become essential for pushing high-frequency performance boundaries. The combination of low-loss materials, stable electrical characteristics, and form-factor flexibility enables designs that simply aren't possible with traditional approaches.

For engineering teams working on cutting-edge high-frequency applications, mastering flexible PCB technology is no longer optional - it's a competitive necessity.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..