Date: 2025-10-25

If you've ever had a vehicle module fail in the field only to find a grainy, dull solder joint as the culprit, you know the stakes. In automotive electronics—from ADAS to powertrain controllers—cold solder joints aren't just a nuisance; they are a critical liability. These weak, incomplete connections often form during high-temperature lead-free reflow and can lead to intermittent failures or sudden system shutdowns.

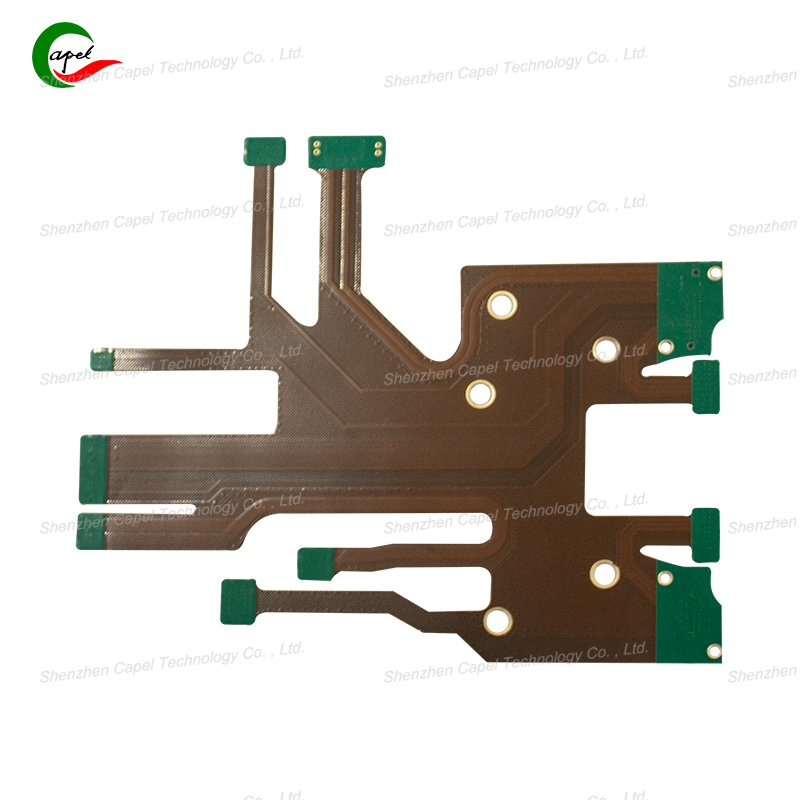

The root of the problem often lies in the PCB itself. Traditional rigid boards struggle with the thermal and mechanical demands of automotive assembly and operation. At our facility, we've found that the solution isn't just about changing the solder paste; it's about adopting a Rigid-Flex PCB structure with a purpose-engineered lead-free pad process. This combination directly tackles the physical and material causes of cold joints.

Let's break down why the traditional approach fails under the hood:

The Thermal Stress Tug-of-War: A rigid FR-4 board, copper pad, and a ceramic component all expand and contract at different rates when blasted to 260°C and then cooled. This CTE mismatch creates immense stress that can crack a solder joint as it solidifies, forming a weak, high-resistance connection from the start.

The Wettability Battle: Lead-free solder (SAC305) is notoriously less "wetting" than its leaded predecessors. If the pad surface isn't perfectly prepared—whether due to a low-quality finish, slight oxidation, or contamination—the solder will ball up instead of flowing smoothly, resulting in a non-bonded "dry joint."

The Structural Problem: A rigid board is, well, rigid. It cannot absorb or dissipate the stresses of the reflow process. All that energy gets transferred directly into the fragile solder joints, making them the primary failure point.

We combat cold joints on three fronts: material science, structural design, and process control.

1. Superior Pad Finishes for Maximum Solder Flow

We've moved beyond basic solder mask over bare copper. For high-reliability automotive applications, we specify:

Electroless Nickel Immersion Gold (ENIG): This is our go-to for critical systems like ADAS. The nickel provides a robust, flat surface, while the thin gold layer ensures the pad remains perfectly pristine and oxidation-free until the moment it hits the solder paste. The result is exceptional wetting every time.

Immersion Silver or High-Quality HASL: For other applications, these finishes provide a strong balance of performance and cost, but they require stricter control over storage and handling to prevent tarnishing.

2. The Rigid-Flex Advantage: Stress Relief Built-In

This is the game-changer. The flexible sections of a Rigid-Flex PCB act as natural stress relievers. During the violent thermal cycling of reflow, these flexible areas absorb the expansion and contraction, preventing that energy from concentrating on the solder joints. It's the difference between a brick and a spring—the spring handles the movement without breaking. We design the board so that sensitive components are anchored on the rigid sections, while the flex zones do the job of managing stress.

3. Process Control Tailored for Lead-Free

A perfect board can be ruined by a poor reflow profile. We work with our clients to dial in their process, focusing on:

A Controlled Thermal Ramp: Avoiding thermal shock to the components and board.

Sufficient Time Above Liquidus (TAL): Ensuring the solder has enough time in its liquid state to fully wet the pads and form a strong intermetallic bond with the nickel or copper underneath.

A Managed Cool-Down Rate: A controlled descent from peak temperature is crucial to prevent the thermal shrinkage that can tear a joint apart.

Based on our experience, here’s what we recommend to ensure solder joint integrity:

For Pad Finish: Specify ENIG for mission-critical modules. It’s worth the marginal cost increase for the reliability payoff.

For Layout: Work with your PCB designer to keep solder joints away from the rigid-to-flex transition zones. Give them a low-stress environment.

For Storage: Treat bare PCBs as sensitive components. Use moisture-barrier bags and controlled storage to prevent pad oxidation before assembly.

For Validation: Don't skip X-ray inspection. It's the only way to see inside the joint to check for voids and poor wetting before the module is sealed and shipped.

The data from our clients confirms the impact. One Tier-1 supplier of engine control units saw their rework rate due to solder issues drop from 8% to under 1% after switching to our Rigid-Flex design with ENIG finish. For them, that translated to hundreds of thousands of dollars in saved labor, materials, and warranty claims.

In the automotive world, a solder joint is more than just a connection; it's a commitment to safety and longevity. By moving to a Rigid-Flex solution with a robust pad process, you're not just fixing a manufacturing headache—you're building a more dependable product.

Struggling with field failures linked to solder joints? Let's talk. Our engineering team can review your design and provide specific recommendations to harden your PCBs against the demands of the automotive environment.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..