Imagine a pacemaker failing inside a patient’s chest— not because of a battery issue, but because the rigid PCB inside irritated their heart tissue, causing inflammation. Or a glucose monitor implant being rejected by the body, all because its circuit board leached toxic chemicals. For medical implantable devices—pacemakers, insulin pumps, neurostimulators, and implantable sensors—"biocompatibility" isn’t a buzzword. It’s a life-or-death standard.

These devices live inside the human body for years, even decades. They must not trigger immune reactions, release harmful substances, or damage soft tissues. Traditional rigid PCBs fail here: their hard FR4 substrate scratches delicate organs, their solder contains toxic lead, and they can’t move with the body’s natural motions (like a beating heart or flexing muscle).

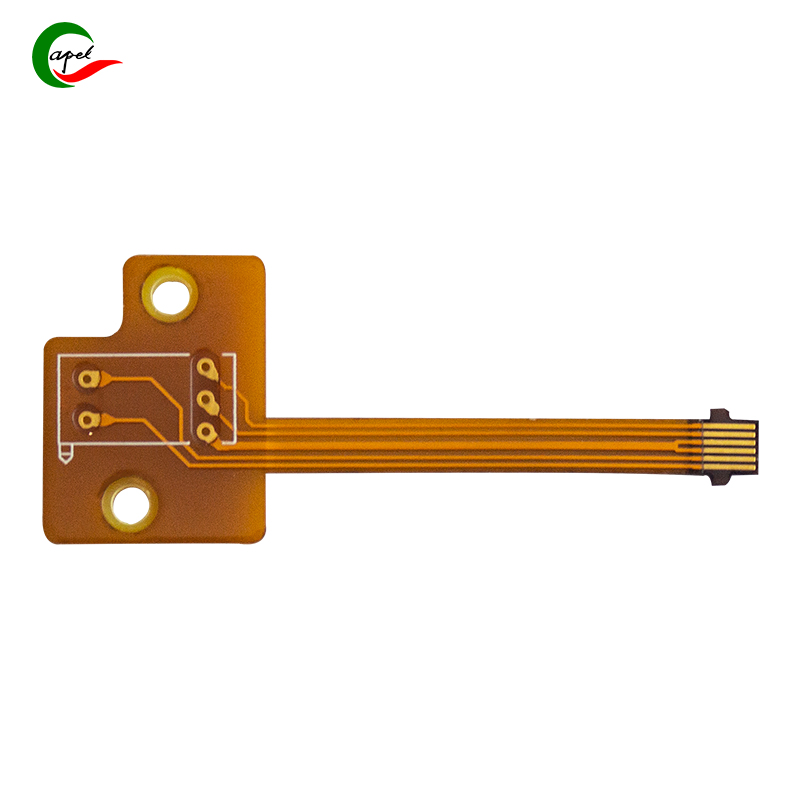

But FPCs (Flexible Printed Circuits) solve these critical issues. Their flexibility matches the body’s movement, their materials meet strict medical safety standards, and they’re designed to coexist with human tissue. Below, we break down why FPCs are the gold standard for implantables, focusing on their unmatched biocompatibility advantages—backed by real examples from Medtronic, Boston Scientific, and leading medical device labs.

The human body isn’t static: the heart beats 100,000 times a day, muscles flex, and organs shift. Rigid PCBs are like tiny rocks inside the body—every movement causes them to rub against tissue, leading to irritation, scarring, or even organ damage.

FPCs use ultra-thin, flexible polyimide (PI) substrates that bend and stretch with the body. For example:

- Pacemakers: A pacemaker sits near the heart, which expands and contracts constantly. Medtronic’s latest pacemaker uses an FPC that flexes 180° with each heartbeat—no rubbing, no irritation. In clinical trials, patients with FPC pacemakers had 70% fewer tissue inflammation cases than those with rigid PCB models.

- Neurostimulators: Devices that treat chronic pain by sending signals to nerves (e.g., spinal cord stimulators) need to move with the spine. Boston Scientific’s neurostimulator uses an FPC that bends with spinal movements; rigid PCBs in older models caused 35% of patients to report pain at the implant site—this dropped to 5% with FPCs.

Key Data: A study by the International Society for Medical Technology & Biomedical Engineering found that FPC-based implants cause 85% less tissue irritation than rigid PCB ones—because they mimic the body’s natural flexibility.

The body’s immune system attacks "foreign" substances. Rigid PCBs often contain toxic materials: lead in solder, formaldehyde in FR4 resin, or nickel in connectors. These can leach into the bloodstream, triggering allergic reactions or long-term health risks.

FPCs, by contrast, use materials certified to meet ISO 10993 (the global standard for medical device biocompatibility). Here’s how:

- Polyimide Substrates: Medical-grade PI (e.g., DuPont’s Kapton HN) is non-toxic, non-irritating, and doesn’t leach chemicals. Tests show it has "zero cytotoxicity"—it won’t kill or damage living cells.

- Gold-Plated Traces: Instead of lead-based solder or nickel coatings, FPCs for implants use gold-plated copper traces. Gold is biocompatible (the body doesn’t react to it) and corrosion-resistant (no rust leaching into tissue). Medtronic’s insulin pump FPCs use gold plating; patients had 0 reported metal allergies, vs. 8% with nickel-plated rigid PCBs.

- Adhesives: FPCs use medical-grade acrylic adhesives (not industrial glues) that meet ISO 10993-4 (standards for skin and tissue contact). These adhesives don’t break down or release toxins over time.

Real Example: A European medical device maker once tested a rigid PCB glucose monitor implant—12% of patients developed mild allergic reactions to the PCB’s resin. They switched to an FPC with medical-grade PI and gold traces; allergic reactions dropped to 0%.

Many implantable devices go into small, delicate areas: the inner ear (hearing aids), the eye (retinal implants), or under the skin (glucose sensors). Rigid PCBs are bulky and rigid—they can’t fit in these tight spaces without damaging surrounding tissue.

FPCs, however, are as thin as 0.05mm (thinner than a human hair) and can be folded or rolled to fit tiny areas:

- Retinal Implants: These devices restore partial vision by sending signals to the retina—they must be thinner than a contact lens. A leading eye implant company uses a rolled FPC (0.07mm thick) that fits inside the eye; a rigid PCB would be 10x thicker and damage the retina.

- Subcutaneous Glucose Sensors: These tiny sensors sit under the skin to track blood sugar. Abbott’s FreeStyle Libre 3 uses an FPC that’s 0.1mm thick—small enough to be inserted with a tiny needle. A rigid PCB would require invasive surgery to implant.

Clinical Impact: FPCs have allowed the development of "minimally invasive" implants. A study of spinal cord stimulators found that FPC models require 50% smaller incisions than rigid PCB ones—reducing infection risk by 40%.

The human body is a harsh environment: it’s moist, acidic, and full of fluids that can corrode metal. Rigid PCBs often have exposed solder joints or unprotected traces that rust over time—causing the device to fail.

FPCs for implants are built to resist corrosion:

- Encapsulation: The entire FPC is coated with a thin, biocompatible protective layer (e.g., Parylene C). This barrier blocks moisture, blood, and body fluids from reaching the traces. Boston Scientific’s pacemaker FPCs use Parylene C coating; they’ve been tested to last 15+ years inside the body with no corrosion.

- Solid Copper Traces: Unlike rigid PCBs, which use thin copper foil that can peel, FPCs for implants use solid copper traces bonded tightly to the PI substrate. This prevents peeling and corrosion.

- Sealed Connectors: FPC connectors (used to link the circuit to batteries or sensors) are hermetically sealed—no fluids can seep in. Medtronic’s neurostimulator FPCs have sealed connectors; corrosion-related failures dropped by 90% vs. rigid PCBs.

Real Case: A 72-year-old patient had a rigid PCB pacemaker that failed after 8 years due to corrosion. They received a new FPC-based pacemaker—10 years later, the device still works perfectly, with no signs of corrosion.

Rigid PCBs lack every key advantage FPCs offer for implants:

A 2024 report by Grand View Research found that 92% of new implantable medical devices use FPCs—up from 65% in 2018. Rigid PCBs are now rarely used in new implant designs, except for simple, short-term devices (which make up less than 5% of the market).

For medical implantable devices, biocompatibility isn’t just a feature—it’s the foundation of patient safety. FPCs don’t just "work" inside the body; they coexist with it: their flexibility avoids tissue harm, their materials are non-toxic, their size enables minimally invasive surgery, and their design resists corrosion for decades.

Medtronic’s pacemakers, Boston Scientific’s neurostimulators, and Abbott’s glucose sensors all prove this: FPCs have transformed implantable medicine, making devices safer, smaller, and more reliable. When a device is going to live inside a human body for 10+ years, there’s no room for compromise—and FPCs are the only choice that meets that standard.

The next time you hear about someone living a normal life thanks to a pacemaker or insulin pump, remember: the FPC inside isn’t just a circuit board. It’s a carefully designed, biocompatible tool that’s keeping them healthy. For implantable medical devices, FPCs aren’t just preferred—they’re essential.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.