Every electronics creator—from startup founders to hobbyists—knows the pain: ordering PCB boards that peel, short out, or can’t handle your device’s needs. You waste time reworking, lose money on faulty batches, and watch launch dates slip. But it doesn’t have to be this way. Our PCB boards are built to fix these headaches—so your devices work, last, and stand out. Let’s break down why we’re the right choice for your next project.

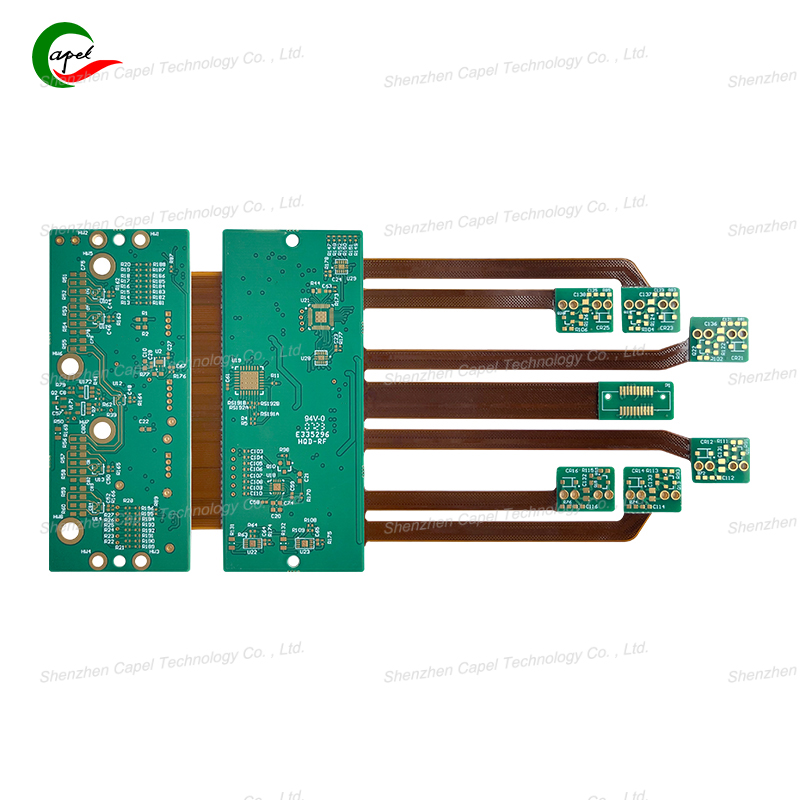

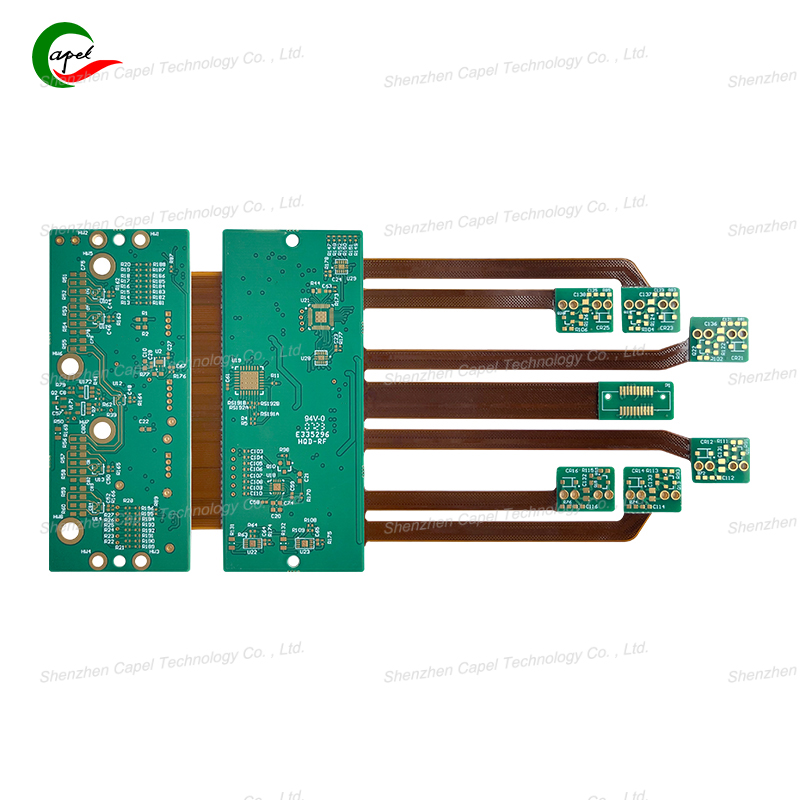

Not every project needs a 20-layer PCB—and not every simple device should settle for a flimsy single-layer board. We tailor our offerings to your needs:

-

Single-layer PCBs: For basic gear like remote controls or simple sensors. Affordable, fast to produce, and tested to avoid trace gaps that cause shorts.

-

Double-layer PCBs: Perfect for mid-range devices (smartwatches, Bluetooth speakers). Our boards use high-quality vias to connect layers—no loose connections that fail after 6 months.

-

Multi-layer PCBs: For high-tech products (medical devices, laptops). We build up to 16-layer boards with dedicated power/ground layers, cutting noise by 50% compared to generic multi-layer PCBs.

A recent client switched to our double-layer PCBs for their smart thermostats—their return rate dropped by 35%, and customers praised the device’s reliability.

Generic PCB suppliers cut corners with paper-based 基材 or thin copper—but we never do. Our boards use:

-

FR-4 fiberglass 基材: Heat-resistant (handles up to 130°C) and warp-proof. Perfect for devices that get warm (LED lights, power banks) or need to last years (industrial sensors).

-

Thick copper options (1oz-4oz): Choose 2oz copper for power-hungry gear (battery chargers) or 4oz for heavy-duty industrial use. No more overheating traces that burn out.

-

Scratch-resistant soldermask: Our green/black/white soldermask is applied evenly (no gaps!) and tested to resist peeling. A garden tech client uses our PCBs for outdoor sensors—they’ve survived rain, dust, and extreme temperatures for 2+ years.

We know your top worries—and we solve them upfront:

-

“What if the PCB doesn’t fit my components?”: Send us your BOM, and our team will pre-check component sizes against the PCB dimensions. We caught a mismatched battery connector for a client last month—saving them from 500 useless boards.

-

“What if the samples fail?”: Order 2-5 prototype boards first. We include a free quality report (AOI test results, copper thickness checks) so you’re 100% sure before scaling up.

-

“What if I need a custom design?”: Our engineers work with you to tweak PCB size, layer count, or coating (like conformal coating for outdoor use). A drone startup needed a compact, lightweight PCB—we redesigned it to save 20% space without sacrificing performance.

We don’t just ship boards—we help you succeed. Our team responds to questions within 8 hours, updates you on production (e.g., “Your PCBs are in soldermask stage”), and even offers post-delivery support (if a board fails due to our error, we replace it for free).

A small electronics brand recently told us: “Switching to your PCBs cut our repair costs by 40% and let us launch 2 weeks early.” That’s the difference between generic PCBs and ones built for your success.

Don’t let bad PCBs ruin your project. Our boards are reliable, tailored to your needs, and backed by a team that cares. Contact us today to get a free quote—and let’s build electronics that work, last, and impress.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.