Date: 2026-01-09

When you’re in the business of building electronic devices, two things are always on your mind: quality and reliability. That often starts with sourcing the right blank PCBs and components. If you’ve been looking into options for blank PCBs and parts, you already know it’s more than just placing an order—it’s about ensuring your foundation is solid.

Let’s talk about what goes into sourcing these essentials and how you can make the process smoother.

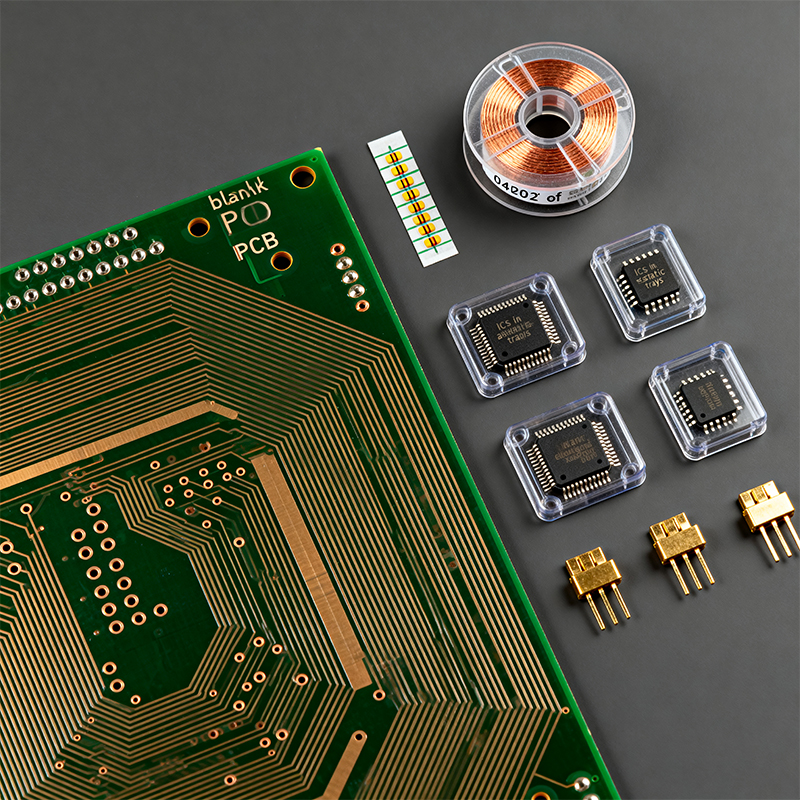

A blank PCB is the bare, unpopulated circuit board—your product’s skeleton. The parts are all the resistors, capacitors, ICs, and connectors that bring it to life. Sourcing them separately gives you flexibility, but it also means managing multiple suppliers, lead times, and quality checks.

Getting this step right affects everything:

Product Performance: Poor PCB materials or counterfeit components can lead to failures.

Production Timelines: Delays in one part can hold up your entire line.

Cost Efficiency: Balancing quality with budget isn’t easy when you’re managing it all yourself.

A lot of manufacturers start out sourcing blank PCBs and components independently, especially for prototypes or small runs. But as volume grows, the complexity often does too.

Finding Reliable Suppliers: Not all PCB fabricators or parts distributors meet international standards.

Supply Chain Surprises: Components go on backorder. Materials become scarce.

Quality Consistency: Verifying every batch takes time and resources.

Hidden Costs: Shipping, tariffs, and minimum order quantities add up.

If any of this sounds familiar, you’re not alone. More manufacturers are exploring streamlined alternatives.

Instead of managing multiple suppliers, many businesses now work with a turnkey PCBA partner. These providers handle everything—from fabricating the blank PCBs to sourcing genuine components, assembling, and testing.

This approach is like having an extension of your team dedicated to production. You provide the design; they handle the rest.

Benefits include:

Single point of contact and accountability

Access to established supplier networks (often with better pricing)

Built-in quality control at every stage

Faster time-to-market

At Kaboer, we run our own PCBA factory in Shenzhen, China. We’ve helped numerous international manufacturers move from sourcing blanks and parts separately to a full turnkey solution.

Our process is straightforward:

You share your design and BOM.

We procure or fabricate the blank PCBs and source all components.

We assemble and rigorously test the boards.

We deliver ready-to-integrate PCBA units.

Whether you need prototypes or volume production, we ensure everything meets international standards and your specific requirements.

If you have a dedicated procurement and assembly team, DIY sourcing might work. But if you’d rather focus on design, sales, and innovation, partnering with a PCBA expert can free up your resources and reduce risk.

Think about:

How much time your team spends on logistics and sourcing.

Whether you’ve faced quality issues with boards or components before.

How quickly you need to scale production.

Sometimes, trying to manage blank PCBs and parts separately ends up costing more in time and stress than expected.

Sourcing blank PCBs and components is a critical step in electronics manufacturing. By understanding the challenges and options available, you can choose the path that best supports your product’s quality and your company’s growth.

If you’re looking for a reliable partner to handle the complexities of PCB and component sourcing and assembly, Kaboer is here to help. Reach out to discuss your next project.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..