Date: 2026-01-09

Over the past few decades, the face of manufacturing has undergone profound changes. A notable trend is the increasing focus of brand companies on product definition, R&D innovation, and marketing, while delegating the production process to specialized partners. This professional division of labor has given rise to and strengthened the electronic manufacturing service industry.

The scope of this industry has long surpassed the traditional concept of “contract manufacturing.” It provides a complete solution—from design collaboration and supply chain management to production delivery—with its core value lying in helping clients navigate the growing complexity of modern manufacturing.

A mature player in the electronic manufacturing service industry can typically handle most stages after a product design is finalized:

Design-to-Production Transition Support

Providing Design for Manufacturability (DFM) analysis during the early design phase to help optimize designs and avoid potential issues that could increase costs or cause delays. This requires engineering teams to understand both design intent and manufacturing processes.

Professional Supply Chain Management

Managing global procurement networks to tackle component shortages, price fluctuations, and quality control challenges. For product companies, this is often a resource-intensive area requiring high expertise.

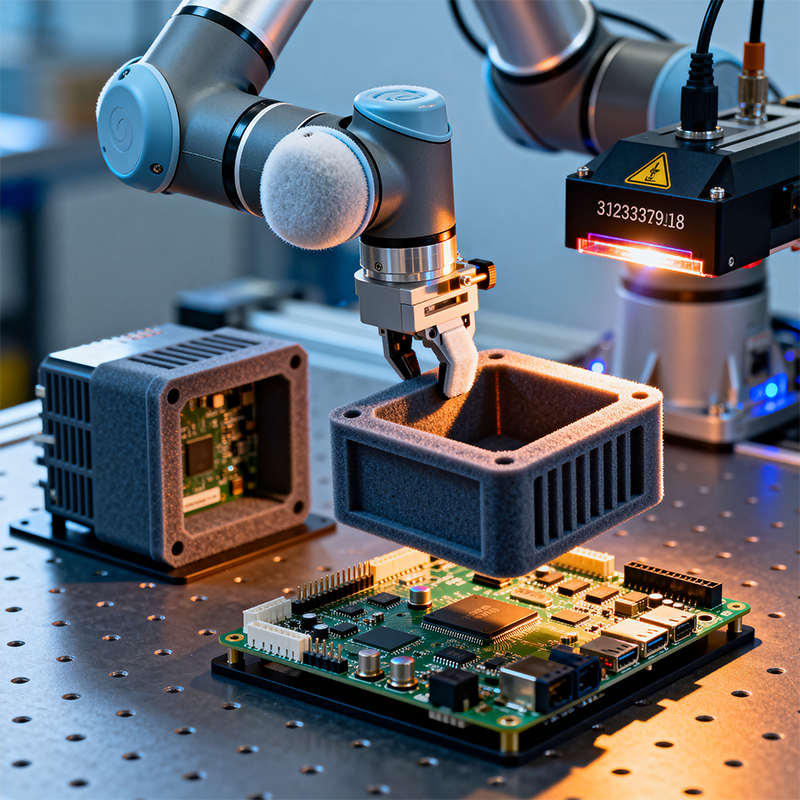

Precision Manufacturing & Process Control

Utilizing automated equipment and strictly controlled process parameters to ensure product consistency from prototype to mass production. This is especially critical in today's environment of component miniaturization and product complexity.

Testing, Validation & Quality Assurance

Building a test regimen from basic to rigorous, not only verifying function but also ensuring product reliability throughout its lifecycle through methods like environmental stress testing.

Final Product Integration & Delivery

Handling downstream work after board-level assembly, such as system integration, software loading, packaging, and logistics, offering a true “turnkey” service.

For companies considering a partnership within the electronic manufacturing service industry, this model typically offers value on several fronts:

Focus on Core Competencies

Channeling internal resources into core areas like product development, technological innovation, and brand building, rather than dispersing energy on factory management.

Access to Scale and Flexibility

Avoiding the risks associated with heavy capital investment and fixed capacity. Companies can leverage the production elasticity of EMS providers to respond flexibly to market demand fluctuations.

Tapping into a Pool of Professional Experience

Benefiting from the manufacturing experience and best practices accumulated by EMS partners across different markets and product segments, thereby enhancing the manufacturability and reliability of their own products.

Accelerating Market Response

Utilizing the mature supply chains and production systems of an EMS partner to significantly shorten the cycle from design to volume production, getting products to market faster.

On the map of the global electronic manufacturing service industry, Shenzhen holds a pivotal position due to its unparalleled electronics industry cluster, efficient supply chain network, and innovative ecosystem. EMS providers here are not only known for achieving an excellent balance of cost and efficiency but are also distinguished by their rapid prototyping capabilities and agile engineering response, which are crucial for today's fast-paced product iteration cycles.

In Shenzhen, EMS companies like Kaboer, which own their factories, have the advantage of deeply integrating local supply chain efficiency with the quality standards, project transparency, and compliance management required by global clients. We are rooted in this dynamic manufacturing ecosystem while possessing the systematic thinking and communication skills needed to serve international customers.

When looking for the right partner within the electronic manufacturing service industry, successful collaboration is often built on the following:

Define Clear Partnership Goals

Articulate the specific objectives you hope to achieve through the collaboration, whether it's cost optimization, quality improvement, capacity assurance, or access to specific process capabilities.

Establish Deep Technical Dialogue

Ensure engineering teams from both sides can communicate effectively early in the design phase, reaching consensus on technical paths and process choices.

Ensure Process Transparency

Establish clear project management and communication mechanisms so that production progress, quality data, and potential issues can be shared promptly and transparently.

Develop a Shared Quality Language

Build a common understanding and expectation regarding quality standards, testing methods, and acceptance processes. This is the foundation of trust for long-term cooperation.

The vigorous development of the electronic manufacturing service industry is an inevitable outcome of the deepening specialization in modern manufacturing. It offers hardware innovation companies an efficient and flexible option for externalized manufacturing. Gaining a deep understanding of this industry's operational models and value proposition is of significant reference value for any company operating in the hardware sector when formulating its manufacturing strategy.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..