Date: 2025-12-30

Introduction: Why Board Type Matters

When you design an electronic product, choosing the right type of circuit board (PCB) is one of your first and most critical decisions. It affects your product's cost, performance, size, and reliability. Think of it like choosing the foundation for a house—the right one ensures everything built on top is stable and functional.

Let's break down the most common types of circuit boards in simple terms.

1. The Basic Choice: Layer Count

The number of conductive copper layers is the primary way to classify PCBs.

Single-Sided PCBs: These are the simplest and most cost-effective boards. They have conductive wiring on only one side of the insulating board. Think of simple, low-power devices like calculators, basic toys, or LED lights. They are great for very basic circuits.

Double-Sided PCBs: The most common type for hobbyist and professional projects. These boards have wiring on both sides, with small holes called “vias” connecting the circuits between layers. This doubles the available space without increasing the board's physical size. You'll find these in most consumer electronics prototypes, automotive dashboards, and industrial controls.

Multi-Layer PCBs: This is where complexity and capability jump. These boards sandwich three or more double-sided layers of circuitry together with insulating material in between. They are essential for compact, high-speed, and high-power devices because they provide dedicated layers for power, ground, and complex signal routing. All smartphones, computers, and advanced medical equipment rely on multi-layer PCBs (often 4 to 12 layers or more).

2. The Flexibility Factor: Rigid vs. Flexible

Next, consider the physical nature of the board material itself.

Rigid PCBs: These are the classic, solid boards we all picture. They are made from a solid material like fiberglass (FR-4) and do not bend. They provide excellent structural support and are used in the vast majority of applications, from your desktop computer's motherboard to a television's control board.

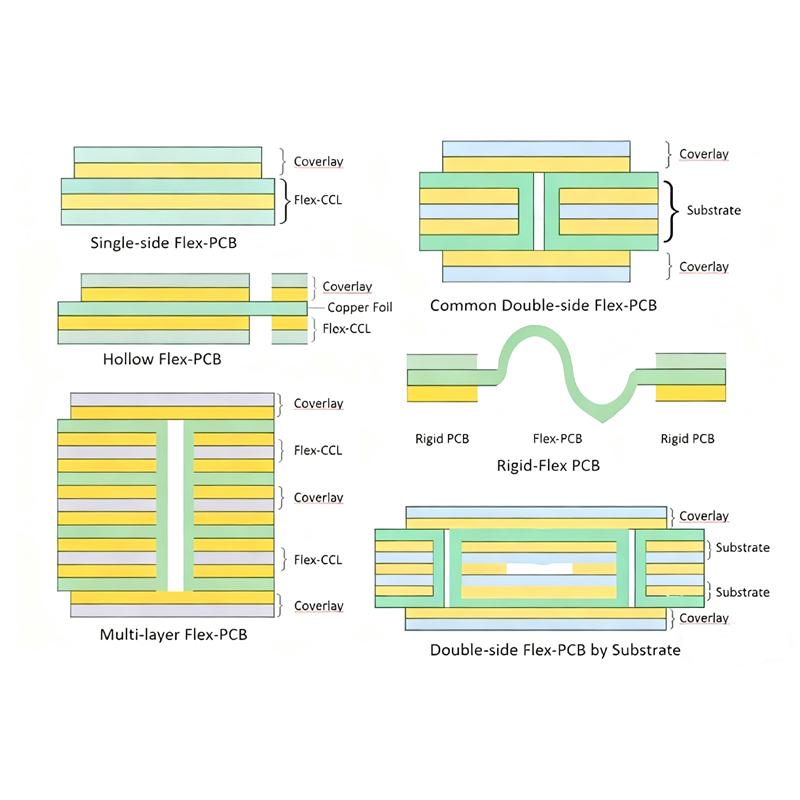

Flexible PCBs (Flex PCBs): These are made from a thin, bendable plastic like polyimide. They can bend, twist, and fold to fit into tight or uniquely shaped spaces. This makes them perfect for wearable devices (smartwatches, fitness bands), modern cameras, and foldable phones, where they save significant space and weight.

Rigid-Flex PCBs: A hybrid that offers the best of both worlds. They combine rigid sections (for mounting heavy components) with flexible sections (for connecting between those rigid parts). This eliminates connectors and wires, creating a more reliable and compact 3D design. They are common in aerospace, military, and advanced medical imaging equipment.

3. The Material Science: Specialized Boards

For extreme applications, the base material changes.

High-Frequency PCBs: Made from special materials (like PTFE/Teflon®) that minimize signal loss. Crucial for 5G/6G communications, radar systems, and satellite technology.

Aluminum-Backed PCBs (Metal Core PCBs - MCPCBs): These have a metal base (usually aluminum) that acts as a super-efficient heat sink. They are the go-to choice for high-power LED lights, automotive systems, and power supplies to keep components cool and extend their lifespan.

How to Choose? Let Kaboer Be Your Guide

Navigating these choices can be complex. The best type for your project depends on a balance of your electrical needs, physical space constraints, thermal management requirements, and budget.

This is where partnering with an experienced PCBA manufacturer from the design phase adds tremendous value.

Why Kaboer is Your Ideal PCBA Partner in Shenzhen

At Kaboer, based in the electronics hub of Shenzhen, China, we don't just build boards—we help you select the right one. Here’s how we simplify the process for global manufacturers:

Expert Guidance from Day One: Our engineering team provides Design for Manufacturability (DFM) reviews. We’ll analyze your schematic and recommend the most cost-effective and reliable board type (e.g., “Will a 4-layer board work better than a complex double-sided design here?”).

Full-Spectrum Manufacturing: Whether you need simple double-sided prototypes, complex 12-layer multi-layer boards, or flexible circuits for a wearable, our factory in Shenzhen is equipped to handle it all.

Supply Chain & Cost Efficiency: Our location gives us direct access to the world's best PCB fabricators and component suppliers. We leverage this network to secure quality materials at competitive prices, ensuring you get the best value.

Quality You Can Trust: From prototyping to mass production, we maintain strict quality control. We ensure that the board type you choose is manufactured to the highest standards, whether it’s a rigid FR-4 board or a sophisticated rigid-flex design.

Conclusion

Choosing the correct type of circuit board is a strategic decision that impacts your entire product. By understanding the core options—layers, flexibility, and material—you can make an informed choice.

Don't navigate this complexity alone. Let Kaboer's expertise guide you from concept to high-quality production.

Ready to build? Contact Kaboer today to discuss your project and find the perfect PCB solution for your next innovation.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..