Date: 2025-12-30

Introduction: From Bare Board to Intelligent Device

Have you ever wondered how a blank, green circuit board (PCB) transforms into the “brain” of your smartphone, laptop, or medical device? The magic happens through a crucial process called PCBA.

If you’re an electronics brand, startup founder, or hardware engineer, understanding “what is PCBA” is essential for bringing your product ideas to life. This guide will explain it in simple terms and show you why getting it right matters.

What Does PCBA Stand For?

PCBA stands for Printed Circuit Board Assembly. It is the finished, functional board you get after all the electronic components are soldered onto a bare PCB.

Think of it this way:

A PCB (Printed Circuit Board) is like an empty city map with roads (copper traces) drawn on it, but no buildings or inhabitants.

PCBA (Printed Circuit Board Assembly) is the thriving, fully built city. The “buildings” (components like chips, resistors, and capacitors) have been placed and connected to the “roads,” making the city (the board) alive and functional.

The PCBA Process Explained Simply

Turning a bare PCB into a PCBA typically involves these key automated steps:

Solder Paste Printing: A thin stencil is placed over the PCB, and solder paste (a sticky mixture of tiny solder balls and flux) is applied precisely where components will sit. Think of it like using a screen-printing stencil to apply glue.

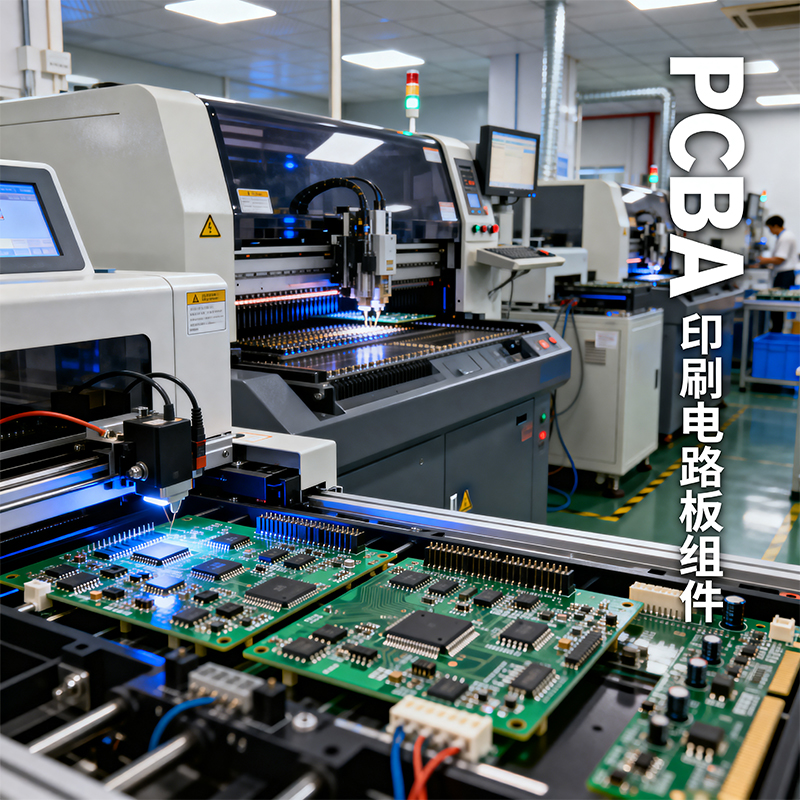

Component Placement: A high-speed, robotic pick-and-place machine picks up tiny components from reels and places them with incredible accuracy onto the solder paste pads. This is the core of Surface Mount Technology (SMT).

Reflow Soldering: The board travels through an oven called a reflow oven. The heat melts the solder paste, permanently bonding the component leads to the PCB pads. The board then cools, forming solid electrical and mechanical connections.

Inspection & Testing: The assembled board undergoes rigorous checks. Automated Optical Inspection (AOI) uses cameras to find missing or misaligned components. Further testing ensures the board powers on and functions as designed.

Why is High-Quality PCBA Critical for Your Product?

Your product’s performance, reliability, and reputation depend entirely on the quality of its PCBA.

Performance: Poor soldering can lead to weak signals, overheating, or circuit failure.

Reliability: A board with hidden defects will fail in the field, leading to costly returns and brand damage.

Time-to-Market: Delays in assembly or multiple prototype revisions can derail your launch schedule.

This is why choosing the right PCBA partner is not just a manufacturing decision—it’s a strategic business decision.

Your Trusted PCBA Partner in Shenzhen: Kaboer

Navigating the complexities of component sourcing, SMT assembly, and quality control can be daunting, especially from overseas. This is where Kaboer provides a clear advantage as your on-the-ground expert in the world’s electronics capital.

Why Global Manufacturers Choose Kaboer for PCBA:

End-to-End Control & Quality: As a company with our own advanced PCBA factory in Shenzhen, we maintain full control over the entire production process. From solder paste inspection to final testing, our quality standards are managed directly, ensuring consistency and reliability for every order.

Supply Chain Mastery: Located in Shenzhen, we are at the heart of the global electronics supply chain. We have established relationships with component distributors, helping us source parts efficiently and mitigate availability risks, which translates to stable costs and reliable timelines for you.

True One-Stop Service: We are more than just an assembly house. Kaboer offers a complete solution:

PCB Fabrication: Sourcing or manufacturing the bare boards.

Component Procurement & Management: Taking the hassle out of parts sourcing.

Advanced SMT & Thru-Hole Assembly: High-mix or high-volume capability.

Rigorous Testing & Box-Build Assembly: Delivering a fully tested module or finished product.

Expertise You Can Rely On: Our engineers provide Design for Manufacturability (DFM) feedback early on, helping optimize your design to reduce costs and prevent assembly issues before production begins.

Conclusion: Bringing Your Ideas to Life Starts with the Right PCBA

Now that you understand what PCBA is, you see it’s the vital bridge between a design file and a tangible, working electronic product. Success depends on precision, expertise, and a reliable manufacturing partner.

Ready to turn your PCB design into a high-quality, assembled reality? Contact Kaboer today for a quote or DFM review. Let’s build your next-generation product together.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..