Date: 2025-07-10

Discover the world of flexible PCBs technology with Kaboer Manufacturing, a leading manufacturer with 16 years of expertise. From the advantages of flexible PCBs to Kaboer’s advanced processes and successful case studies, find out how their innovative solutions meet different needs industry needs.

Flexible PCBs, also known as flex circuits, are a key component of modern electronic devices due to their ability to bend and bend during use. They offer significant advantages over traditional rigid PCBs, making them ideal for applications where space and weight are critical.

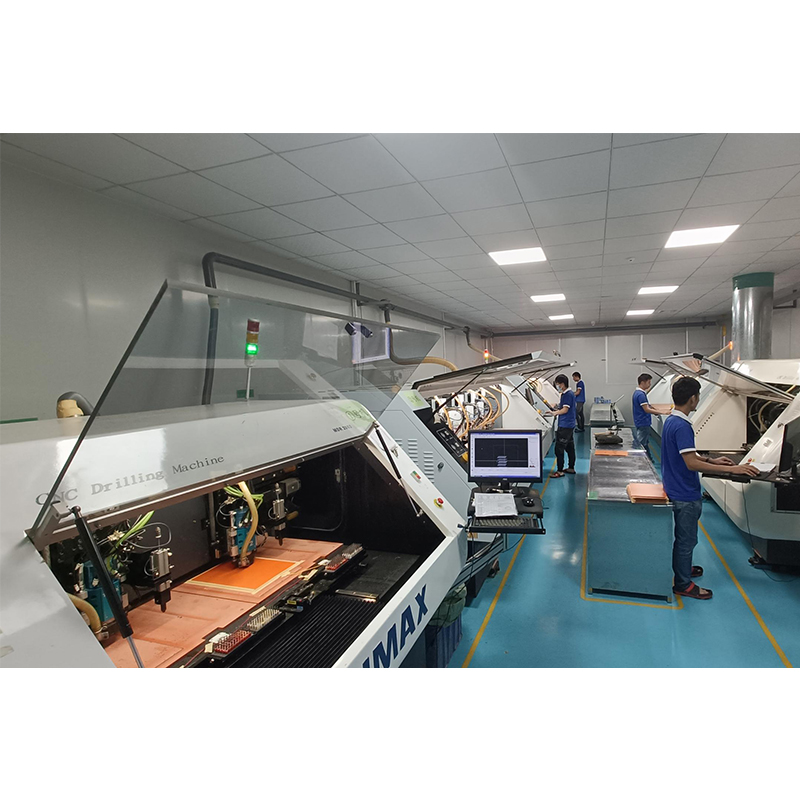

Kaboer Manufacturing is a leading flexible PCB manufacturer with 16 years of industry experience. The company has built a strong reputation for its advanced technology, proven processes and successful case studies of solving industry-specific challenges for clients. Kaboer’s flexible PCB processes and technologies reflect the advantages of technological innovation, strength, professionalism, advanced process capabilities, strong R&D capabilities and advanced technology in flexible PCB manufacturing.

Flexible PCBs are made of flexible substrates such as polyimide or PEEK, which can be bent without breaking. They are widely used in applications where space and weight are critical, such as aerospace, medical devices and consumer electronics.

Flexible PCBs offer several advantages over rigid PCBs, including reduced space requirements, reduced weight, improved reliability, and enhanced design flexibility.

The number of layers in a flexible PCB is critical in determining its functionality and performance. Different ply options are available to meet specific application needs, and Kaboer Manufacturing’s expertise in producing a variety of ply options reflects its versatility and functionality.

Flexible PCB configurations range from single layer to multi-layer, with each configuration providing unique advantages for specific applications. Kaboer Manufacturing’s advanced capabilities are demonstrated by its ability to produce 1-30 layer flexible PCB prototyping and manufacturing.

Kaboer Manufacturing has rich experience and advanced technology to produce flexible PCBs with a variety of layer options to meet the needs of different industries.

Different layer options in flexible PCBs address specific application requirements, such as high-density interconnect (HDI) for complex electronic designs, and Kaboer Manufacturing’s expertise in this area reflects its commitment to meeting diverse customer needs.

Kaboer Manufacturing offers a full range of flexible PCB products, including single-sided, double-sided, single-layer, double-layer and multi-layer flexible PCBs, to meet a wide range of industry applications.

Each type of flexible PCB offered by Kaboer Manufacturing is tailored to specific application requirements, with unique features and capabilities that reflect the company’s commitment to technological innovation and advanced craftsmanship.

Kaboer Manufacturing’s flexible PCBs offer high-density interconnect capabilities, specialized processes and advanced features to meet the ever-changing needs of the electronics industry.

Kaboer Manufacturing’s flexible PCBs adhere to strict technical specifications, including precise line widths and spacing of 0.035 mm, reflecting the company’s commitment to precision and quality.

The precision and quality of Kaboer Manufacturing’s flexible PCB manufacturing process is reflected in its adherence to strict technical specifications, ensuring the reliability and performance of its products.

Kaboer Manufacturing offers customization options to meet specific customer requirements, demonstrating its flexibility and commitment to providing customized solutions for diverse applications.

Flexible PCBs offer unparalleled versatility and functionality, making them indispensable in modern electronic devices and applications.

Kaboer Manufacturing’s expertise in producing high-quality flexible PCBs with multiple layer options reflects its commitment to technological innovation and advanced craftsmanship.

Readers are encouraged to explore the many possibilities of flexible PCBs and leverage Kaboer Manufacturing’s expertise to meet their specific application needs, and benefit from the company’s advanced technology and successful case studies in solving industry-specific challenges.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..