Date: 2025-07-11

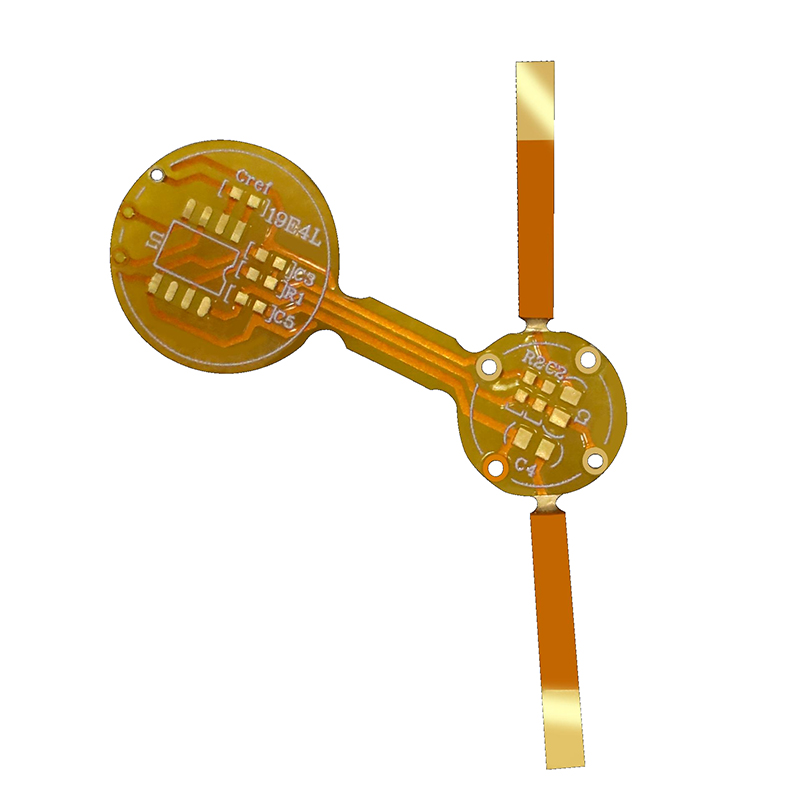

Single-sided flexible PCB (Single-sided flexible PCB) is an electronic circuit board made of flexible substrate materials. It only has wires and circuit components on one side, while the other side is a bare flexible substrate. This design makes the single-sided flexible board very thin, light, flexible, and has high bending performance. They can be zigzag installed on the curved surface of the equipment or in the limited space, so as to realize the connection and function of the circuit. The advantages of using single-sided flexible boards over conventional rigid circuit boards include small size, light weight, good flexibility, and strong vibration and impact resistance.

Single-sided flexible circuit boards are flexible circuit boards that are widely used in the field of sensor technology in the automotive industry.These boards are commonly used to integrate sensors into various components of the vehicle, such as airbags, anti-lock braking systems (ABS),engine control units (ECUs), and temperature sensors. The flexibility and compactness of these boards make them ideal for housing sensors in the tight spaces of automotive applications.Single-sided flexible circuit boards offer advantages such as reduced weight, increased durability, and the ability to adapt to irregular shapes and contours, making them ideal for sensor integration in the automotive sector.

During the whole project cooperation period, Capel Technology Co., Ltd. has demonstrated its super technical level and super high professionalism, and finally won the high recognition of Volkswagen partners.

Demand analysis: At the beginning of the project, Capel had 15 years of professional technical engineering R&D team and the Volkswagen team conducted a detailed demand analysis, and determined the specific requirements for the application of single-sided flexible boards in automotive sensor systems. This includes the type and quantity of sensors, the size and shape requirements of the flexible board, and the circuit connection requirements with other components,etc.

Design and development: Based on the results of demand analysis. Capel’s technical engineering R&D team began to design and develop single-sided flexible boards. Designers use software tools and CAD technology to create the circuit diagram and layout design of the flexible circuit board, taking into account the integration with the Volkswagen sensor system.

Material selection: During the design process, the Capel team selected materials suitable for the automotive environment, such as polyimide These materials have excellent properties such as high temperature tolerance, vibration resistance, chemical resistance and electrical insulation to meet the requirements of automotive sensor systems. Manufacturing and Production: When the FPC design was completed and verified, the Capel team started the manufacturing and production process. Following the strict process flow, combined with ultra-high process capability and advanced imported fully automated equipment, the circuit diagram is transformed into actual flexible circuit board products, including control circuit, welding, and testing and other processes.

Integration and testing: The manufacturing process of single-sided flexible boards requires rigorous testing and verification to ensure the performance and reliability of the sensor. The testing and validation phase typically includes electrical testing, temperature and environmental stability testing, and high-speed data transmission testing, among others Through these tests, the function and reliability of single-sided flexible boards in automotive applications can be guaranteed.

The completed single-sided flexible circuit board is transferred to Capel’s electronic component placement and testing factory for integration and testing with the sensor system. Connect flex boards to sensors and other electronic components and ensure proper operation and accurate data in real-world use.

System optimization and iteration: In the process of integration and testing, some problems or improvement points are found. The Capel engineering technology R&D team and the Volkswagen team have been maintaining technical discussions and close cooperation, step by step system optimization and iteration, and finally ensured that the performance and reliability of the single-sided flexible circuit board reached the best state.

Driving test and verification: Finally, Volkswagen conducted a driving test and verification to ensure that the single-sided flexible circuit board operates normally under actual road conditions, and the performance and data accuracy of the sensor system meet the expected requirements.

Provide thin and flexible solutions: Single-sided flexible circuit board technology provides thin and flexible solutions for sensors, which can adapt to the space constraints of different parts of Volkswagen. Compared with traditional rigid circuit boards, single-sided flexible boards can be more flexibly arranged and installed in every corner of the car. providing more optional locations and installation methods. Improved Durability and Vibration Resistance: Single-sided flex circuit technology enhances sensor durability and vibration resistance. The softness and elasticity of the soft board can reduce the impact of external impact and vibration on the circuit board, thereby improving the stability and reliability of the sensor. This is very important for different road conditions and vibration environments during driving.

Improve response speed: The flexible nature of single-sided flexible boards enables them to adapt to the complex shapes of automotive parts and structures, providing better mechanical adaptability. This means that the single-sided flexible board can arrange sensors in the narrow space of the vehicle, improving the reliability and response speed of the system.

Improve reliability and performance: Single-sided flexible boards usually use polyimide (PI) as the base material because of its excellent heat resistance, chemical stability and mechanical strength. PI materials remain stable at high temperatures and harsh environments, making them ideal for automotive applications. Integrated circuit (IC) embedding: The single-sided flexible board can directly embed IC chips in it, making the sensor system more compact and integrated. By integrating ICs on a single-sided flexible board, the connection lines between circuits can be reduced, thereby improving system reliability and performance.

Improved data accuracy: Sensors using single-sided flex sheets in vehicle safety systems can detect and measure important parameters such as crashes, braking, and stability to ensure vehicles remain safe in various situations. And because the single-sided flexible board has the characteristics of flexibility, lightness and plasticity, it can better adapt to complex vehicle structures, maintain stability under harsh conditions, provide good signal transmission, and provide accurate sensing data.

Detection accuracy: A single-sided flexible board sensor is used to monitor the surrounding environment of the vehicle to provide better driving assistance functions. The flexible characteristics of the single-sided flexible board enable the sensor to better adapt to the vehicle surface and provide more accurate and reliable environmental perception data.

Reduce the risk of connecting electronic components: Single-sided flexible board technology reduces the risk of connecting electronic components by reducing connection points and connecting lines. The fewer connection points and wires between the electronic components inside the sensor, the lower the complexity, vulnerability and failure rate of the system. The application of single-sided flexible board technology can reduce the number of connection points, thereby improving the reliability of the sensor.

Provide better dustproof and waterproof performance: single-sided flexible board technology provides better dustproof and waterproof performance, protecting the sensor from the external environment such as dust, moisture, and water. This is very important for reliable operation in the harsh external environment of the car, such as rain, mud, or harsh weather.

Reduce energy consumption: Single-sided flexible circuit board technology adopts efficient circuit layout and optimized circuit design, which can reduce the energy consumption of sensors, better integrate with automotive structures and parts, and reduce the material and space requirements of circuit boards. This not only reduces the weight of the car and improves fuel efficiency, but also helps reduce waste in the production process, contributing to energy saving and environmental protection in the automotive industry.

Compared with traditional rigid circuit boards, the design of single-sided flexible boards is more compact, and the distance between circuits and the length of wires are shorter, thereby reducing the loss of energy transmission and improving energy utilization efficiency.

Improve system integration capabilities: The flexible design and high-density connection of single-sided flexible boards enable them to be effectively integrated into sensor systems, and its technology can realize the integration of a variety of different sensors. By integrating multiple sensors into a flexible circuit board, the connection points in the system can be reduced, the size of the hardware can be reduced, the efficiency of information exchange can be improved, the failure rate of the overall system can be reduced, and collaborative work and data exchange can be realized.

Enhanced product safety: Single-sided flexible board technology can provide higher product safety by adopting higher fire resistance and insulation materials, improving the fire resistance and insulation performance of sensors. This is especially important for safety systems and key control modules in cars, reducing the risk of fire and safety accidents caused by short circuits and other failures.

Improve cost and space efficiency: Compared with traditional rigid circuit boards, single-sided flexible boards have lower manufacturing costs. They can reduce production costs and reduce material waste through mass production and automated manufacturing processes; the flexible nature of single-sided flexible boards means that they can be custom-made according to space constraints and automotive structural requirements. Sensor systems can fit compactly in tight spaces inside vehicles, providing more accurate and timely data.

Capel’s single-sided flexible board technology not only brings advantages in safety, high integration, reliability, energy consumption and overall system performance, but also provides better design flexibility, lower costs and ease of maintenance and Advantages in maintenance and other aspects, which make Capel’s flexible circuit board technology widely used in the automotive industry and other fields, and promote the development of sensor technology.

Technical innovation ability: Capel has 15 years of professional technology accumulation and experience in the field of automotive flexible boards, and has strong innovation capabilities in product design, development and manufacturing. Volkswagen chose to cooperate with Capel because Capel can technically meet Volkswagen’s needs for continuous innovation and product quality improvement.

Quality management ability: Capel has a strict quality management system and process, which can ensure the high quality and reliability of products. In the automotive industry, quality is a very critical factor. Volkswagen is very satisfied with Capel’s product quality management, which shows that Capel’s ability in quality has been highly recognized.

Responsive speed and customer service: Capel can respond to Volkswagen’s needs in a timely manner and provide excellent customer service. Capel is able to meet Volkswagen’s needs within a tight time frame, and can provide comprehensive technical support and solutions, which increases Volkswagen’s recognition and trust in Capel.

Cooperation attitude and values in cooperation: In the long-term cooperation, Capel has shown a good cooperation attitude and strong cooperation willingness, and is consistent with Volkswagen’s cooperation values. During the cooperation, the two parties can establish a good communication and cooperation relationship and pursue common goals. Volkswagen attaches great importance to Capel’s technology, experience and strength.

Choose Capel as a partner: Volkswagen has chosen Capel as a supplier of flexible circuit boards among many suppliers, which shows their recognition of Capel’s technical strength, production capacity and quality management. This selection is often the result of a rigorous evaluation and selection process.

Long-term cooperative relationship: Capel has established a long-term cooperative relationship with Volkswagen, and the two parties have also achieved excellent results in past cooperation and trust each other. Volkswagen’s willingness to cooperate with Capel for a long time shows that they highly recognize Capel’s ability and contribution.

Scope and scale of cooperation projects: The cooperation projects between Capel and Volkswagen have a relatively large scale and importance, such as the key components specified by Volkswagen, which means that Volkswagen has a higher degree of recognition of Capel. For such projects, Volkswagen usually conducts rigorous audits and tests on suppliers to ensure that they meet high quality and reliability requirements.

Highly satisfactory performance evaluation: Volkswagen evaluates Capel’s performance and gives a highly satisfactory evaluation. This includes evaluations of product quality, on-time delivery, technical support, and more. Capel got a high score in the performance evaluation, and Volkswagen recognized Capel’s ability and value even more.

Volkswagen partners’ high recognition of Capel can be reflected in partner selection, long-term cooperative relationship, scale and importance of cooperation projects, and performance evaluation. These recognitions prove Capel’s dominant position and good reputation in the automotive industry, and bring more opportunities and success to the cooperation between the two parties.

Volkswagen highly recognizes Capel’s professional technology, experience and strength in single-sided flex pcb, which is in line with Capel’s technical innovation capabilities, quality management capabilities, response speed, customer service, and cooperative attitude in the circuit board industry. are closely related to values. These recognition reflect the long-term excellent performance and outstanding achievements of Shenzhen Capel Technology Co., Ltd.’s flexible boards in the automotive industry.

Capel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..