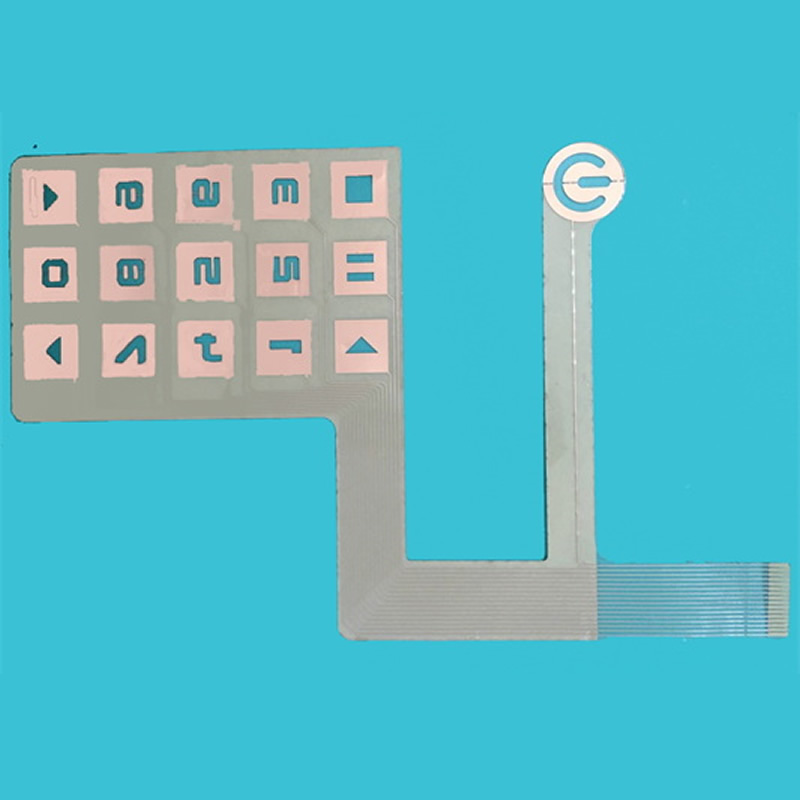

Product Type:1 layer Flexible PCB Boards

Applications: Industrial control panel

Material: PET, Copper,adhesive

Line width and line spacing:0.15mm/0.15mm

Board thickness:0.13mm +/-0.03mm

Layers Stackup:1

Minimum hole:N

Copper Hole Thickness:/

Surface Treatment:ENIG 2-3uin

Impedance:/

Warpage:/

Tolerance tolerance:±0.1MM

Capel’s Service:

Support Custom 1-30 Layer FPC Flexible PCB,2-32 Layer Rigid-Flex Circuit Boards,1-60 Layer Rigid PCB,HDI PCB,Reliable Quick Turn PCB Prototyping,Fast Turn SMT PCB Assembly

Industry We Service:

Medical Device, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

juicer pcb | juicer press flex pcb | industrial control circuit board

juicer pcb | juicer press flex pcb | industrial control circuit board Car Wiper Flexible PCB | Car FPC | Automotive wiper circuit board | Automotive Wiper FPC

Car Wiper Flexible PCB | Car FPC | Automotive wiper circuit board | Automotive Wiper FPC Automotive lighting PCB | Single-sided automotive FPC |automotive circuit board | Central lighting FPC

Automotive lighting PCB | Single-sided automotive FPC |automotive circuit board | Central lighting FPC High-quality Single-Side Flexible Boards PI FR4 PCB Fab for Heart Rate Monitors

High-quality Single-Side Flexible Boards PI FR4 PCB Fab for Heart Rate Monitors Rapid Flex Pcb Manufacturing Maker Online Single Layer Pcb Price

Rapid Flex Pcb Manufacturing Maker Online Single Layer Pcb Price Instant Pcb Quote Single Sided Flex Board Prototype Service

Instant Pcb Quote Single Sided Flex Board Prototype ServiceCapel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..