Date: 2026-01-04

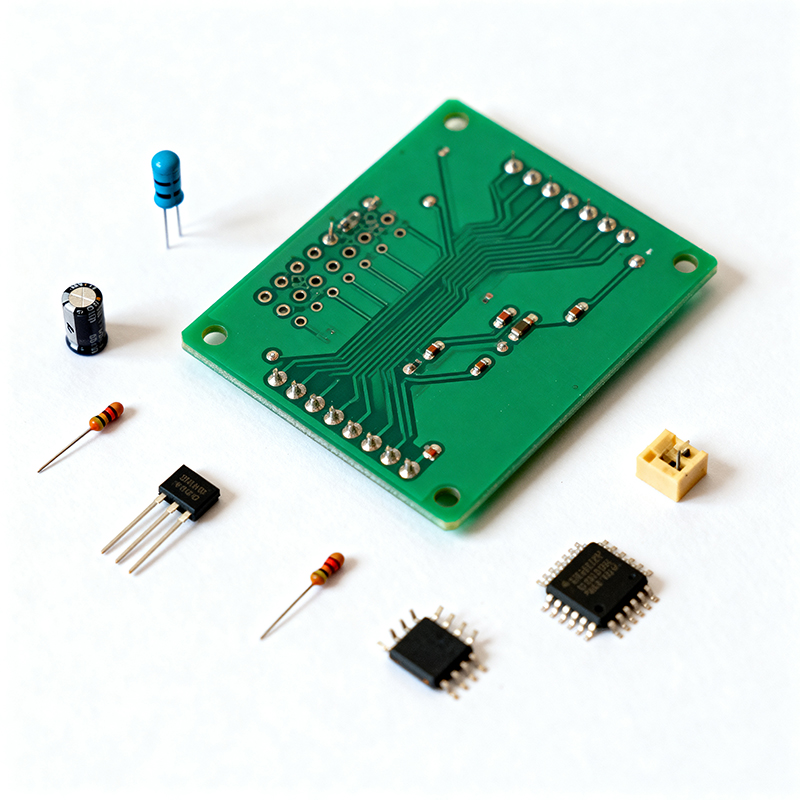

ou typically end up with two important sets of deliverables: one for the bare PCB and another for the component list. These correspond to the two physical foundations of the final product—the blank circuit board and the electronic components waiting to be installed.

The blank PCB is like a city plot with all the roads and foundations laid out, but no buildings yet. The copper traces are the carefully planned “circuit roads,” the pads are the reserved “building foundations,” and the vias are the “elevator shafts” connecting different floors. The board’s material, layer count, copper weight, and surface finish determine the physical capability of the final circuit.

The electronic components are the various functional buildings to be constructed on this land. The microprocessor acts as the command center, memory chips are the archives, resistors and capacitors are like infrastructure, and various interface chips serve as stations and ports connecting to the outside world. Each component has its unique electrical characteristics, physical size, and mounting requirements.

With a well-designed PCB and carefully selected components, the next step is to combine them into a functional whole. This assembly process—board assembly—may seem straightforward but involves many steps requiring specialized knowledge and technical equipment.

Sourcing and Matching

Even with common components like resistors and capacitors, subtle differences exist between brands and batches. More complex chips may involve lead time, price fluctuations, or even obsolescence risks. Ensuring all parts arrive on time with consistent quality requires established supply chain management and quality inspection processes.

Precision Assembly Processes

Modern electronic components are shrinking, some so small that their orientation is hard to distinguish with the naked eye. Placing them accurately requires professional SMT (Surface Mount Technology) equipment. These machines handle thousands of tiny components with remarkable speed and precision—a level of efficiency and consistency nearly impossible to achieve manually.

Quality Assurance Steps

After soldering, how do you confirm every connection is solid and reliable? This is especially true for solder joints hidden beneath chips, invisible to direct view. Modern electronics manufacturing relies on multiple inspection methods: optical checks, X-ray inspection, electrical testing, and more, ensuring every completed board meets design specifications.

In electronics manufacturing, companies typically choose the production path that best fits their situation. Some manufacturers with specialized equipment and teams establish their own production lines, handling everything from procurement to assembly in-house. This approach requires significant upfront investment and ongoing technical maintenance.

Another common practice is partnering with a professional PCBA manufacturing service provider. These providers usually have complete production lines and established component sourcing channels, enabling them to quickly transform a customer’s design into a manufacturable finished board. Kaboer, based in Shenzhen, is such a provider. We operate our own production facility, offering clients end-to-end services from PCB fabrication and component procurement to assembly and testing.

For companies that prefer to focus on product design and market development, working with a professional PCBA manufacturer can free their team from complex production management. A professional manufacturer brings not just equipment and technology, but also accumulated experience in component supply chains, production processes, and quality control. This experience helps mitigate project risks and accelerate time to market.

Regardless of the chosen path, understanding the complete transition from design files to physical circuit boards helps in making decisions that better align with project needs.

This content is provided by Kaboer PCBA Factory in Shenzhen. We specialize in transforming electronic designs into reliable hardware products, offering manufacturing solutions from prototype to volume production for our clients.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..