Date: 2026-01-04

If you come across the term Circuit Card Assemblies in supplier materials or industry discussions, it might sound a bit formal. In essence, it refers to the same thing as the more common PCBA: a Printed Circuit Board Assembly.

It often comes down to terminology preference. In certain sectors—particularly aerospace, military, or some high-reliability industrial fields—people tend to use “Circuit Card Assemblies” or “CCA.” It can sound more formal and emphasize its role as a complete functional unit. “PCBA” is more prevalent in consumer electronics and broader commercial manufacturing.

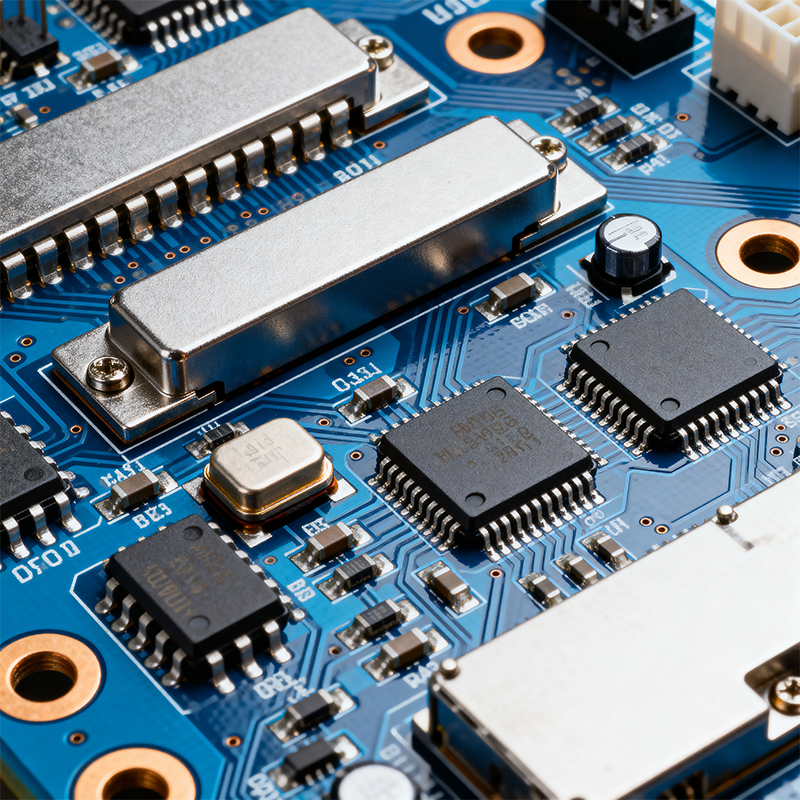

So, when you search for “Circuit Card Assemblies,” you are fundamentally looking for a module where all electronic components (ICs, resistors, capacitors, connectors, etc.) are precisely mounted and soldered onto a printed circuit board, creating a fully functional electronic unit. If you'd like a primer on this assembly process, you can check out our basic guide on what a PCBA is: what is pcba?.

For a reliable Circuit Card Assembly, having all components soldered in the right place is just the starting point. Especially for demanding applications, its reliability, consistency, and long-term performance are what truly matter. This hinges on meticulous processes and controls:

Designing with Manufacturing in Mind

A well-designed CCA has manufacturability built into it. This means the circuit layout considers ease of production, test access, and repairability from the outset. A good manufacturer provides Design for Manufacturability analysis, optimizing the design before it hits the production floor to avoid costly revisions later.

Process Control Dictates Long-Term Reliability

Solder joint quality is the foundation of a CCA's lifespan. This encompasses everything from solder paste printing accuracy and precise reflow oven temperature profiles to potential X-ray inspection for hidden joints under components like BGAs. Rigorous process control aims to eliminate cold joints, voids, or stress points, ensuring stability under vibration, thermal cycling, and other environmental stresses.

Testing is the Ultimate Validation

From in-circuit tests checking electrical connections to functional tests verifying overall performance, and possibly environmental stress screening, the comprehensiveness and rigor of the test strategy directly reflect the final quality. A customized test plan ensures the assembly meets its specific application demands.

Choosing the right manufacturing partner becomes critical for complex or high-stakes projects. A partner with its own factory, like Kaboer in Shenzhen, offers decisive advantages:

Deep Control for Assured Quality

We manage the complete process in-house, from component procurement and SMT assembly to testing and packaging. This depth of control allows us to enforce the quality standards tailored for your project rigorously, ensuring consistency from the first prototype to the ten-thousandth production unit.

Seamless Communication for Faster Resolution

When engineering questions or mid-stream adjustments arise, our engineers can collaborate directly with the production team without the communication barriers of outsourcing. This efficiency helps shorten project timelines and adapt to unforeseen changes.

Focus on Demanding and Complex Projects

We understand that clients seeking “Circuit Card Assemblies” often have expectations that go beyond standard consumer electronics—higher performance, greater reliability. Leveraging the flexibility and deep process control of an owned factory, we focus on supporting these more challenging projects, ensuring your design intent is translated into hardware accurately and reliably.

Choosing a CCA manufacturer isn't just selecting a vendor; it's choosing a long-term partner who understands your technical goals and can translate them into dependable hardware.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..