Date: 2026-01-04

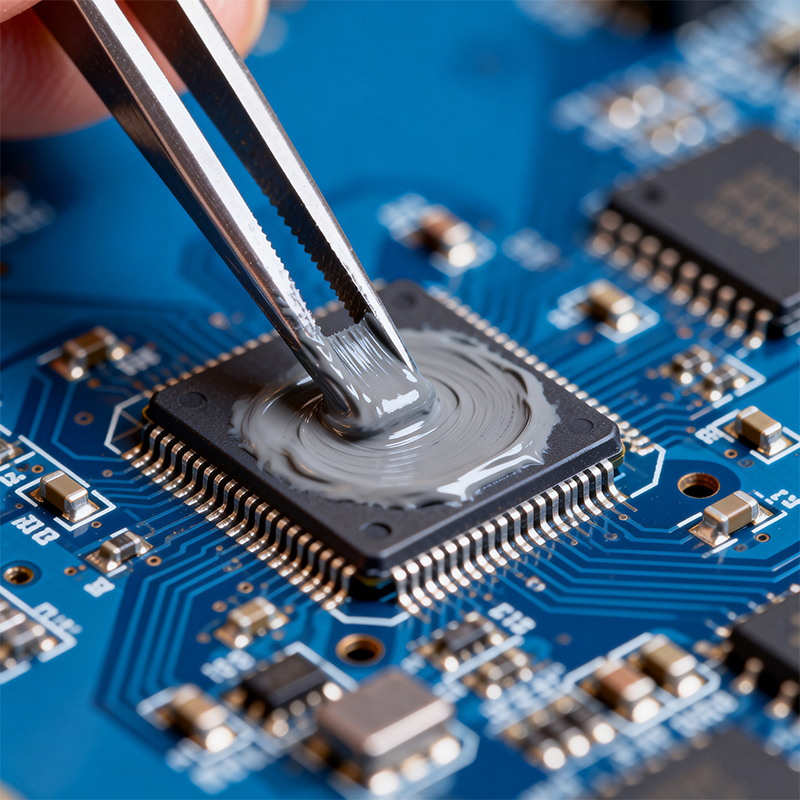

If you’re searching “what is soldering paste used for,” you might be standing next to an SMT line, watching that grey, toothpaste-like material being precisely printed onto circuit boards. Or perhaps you’re a hardware engineer, and someone in a design review mentioned “this pad design needs to consider solder paste printability.” You’re probably thinking: Isn’t this stuff just for holding components in place? Why is everyone making such a big deal about it?

Your instinct is correct, but only part of the story. Solder paste is indeed the lifeblood of modern electronics assembly, but its role is far more complex than just being a “glue.” Understanding it is crucial for building reliable products.

In simple terms, solder paste is a fine mixture of metal solder powder, flux, and small additives. On the SMT line, its “job journey” and critical functions can be broken down into three acts:

Act 1: Precise Positioning – The “Temporary Glue” for Components

Before the high-speed pick-and-place machine puts components onto the PCB, solder paste has already been stencil-printed onto every pad that needs soldering. At this stage, it’s slightly tacky. This tackiness “gently holds” tiny components—resistors and capacitors so small they’re hard to see—in place, preventing them from shifting due to conveyor vibration before they enter the high-temperature oven. This is its most visible job: stabilizing components before the soldering even begins.

Act 2: Precision Soldering – The “Metallurgist” Forming the Connection

The real magic happens when the board enters the reflow oven. First, the flux in the paste activates, cleaning oxides from the pad and component lead surfaces. Then, as the temperature rises past the melting point of the solder alloy, the metal powder melts. Driven by surface tension, it automatically forms a smooth, strong, “concave fillet” solder joint between the component lead and the PCB pad. This is its core mission: creating a permanent, electrically conductive, and mechanical bond.

Act 3: Quality Indicator – The “Canary in the Coal Mine”

An experienced process engineer can predict many issues just by looking at the solder paste after printing, even before soldering. Is the paste deposit full and round? Are the edges sharp and defined? Is there any smearing or bridging? This directly reflects the quality of the stencil design, printer settings, and even the PCB pads themselves. Therefore, solder paste print quality is the “first critical checkpoint” for the entire SMT process. If this checkpoint fails, problems will multiply down the line.

If you think “all solder paste is pretty much the same,” you might be in for unexpected headaches during production. The choice of paste is dictated by your product’s needs:

Boards with Mixed Component Sizes: If your board has large connectors right next to tiny 0201 resistors, you need a paste with excellent “anti-slump” properties to prevent it from spreading during heat and causing shorts.

Boards with Bottom-Side Components: For double-sided assemblies, the paste used for the second side needs a special formulation to prevent already-soldered components on the bottom from re-melting and falling off.

High-Reliability Products (e.g., automotive): You might need a silver-bearing paste for stronger joints or a no-clean paste with very low residue.

Special Processes: For techniques like Pin-in-Paste (PIP) reflow, the paste formulation and printing method are entirely different.

At Kaboer’s factory in Shenzhen, a key part of our process engineers’ daily work is selecting and validating the right solder paste based on the specific characteristics of a client’s board (component layout, PCB surface finish, end-use). We know that using the right material is the first step in making a good product. The wrong paste can lead to poor soldering, weak joints, or long-term reliability failures—costs that far exceed any small difference in material price.

So, the next time you see or think about solder paste, we hope you see it not just as a consumable in production, but as a silent yet crucial guardian of your product’s quality and reliability chain. Choosing and applying it well is worth your attention.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..