Date: 2026-01-06

If you're designing LED lighting, power modules, or automotive electronics and find that regular FR-4 boards are getting "too hot to handle"—with components overheating, performance dropping, or lifespan shortening—then searching for "aluminum PCB" is the right move.

Simply put, an aluminum PCB is a special circuit board that quickly "carries away" heat. It doesn't rely on fans or heatsinks; it uses its own metal substrate.

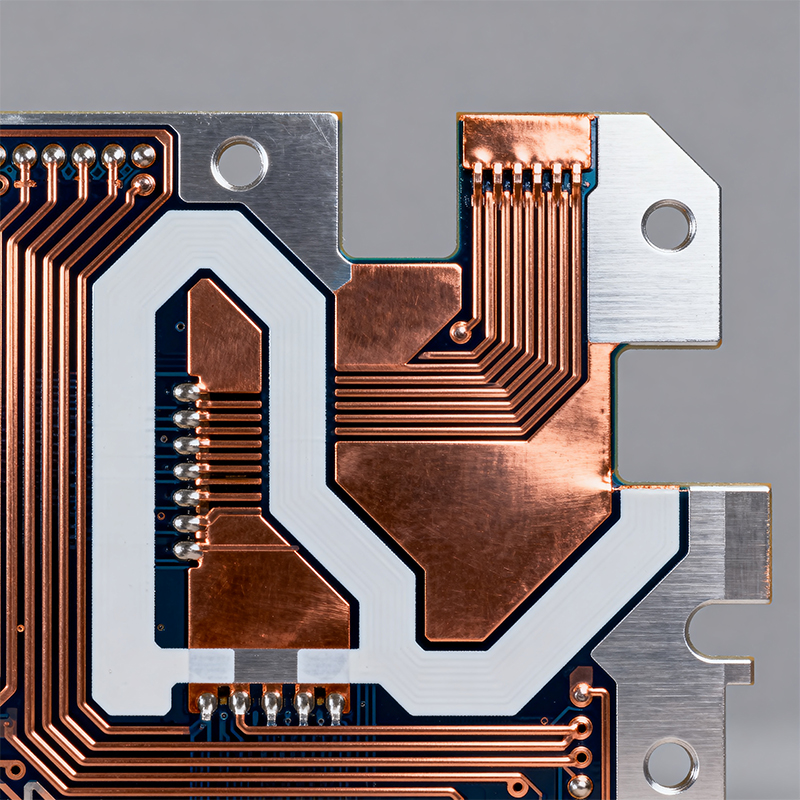

Think of it like a sandwich:

Top Layer: The circuit layer (copper foil), same as a regular PCB, where components are soldered.

Middle Layer: The key—a thin layer of thermally conductive insulation material (usually 0.1-0.2mm thick).

Bottom Layer: An aluminum plate (typically 1-3mm thick), the real workhorse for heat dissipation.

This structure allows heat to transfer quickly from hot components to the aluminum base, then dissipate into the air. The cooling efficiency is often 5-10 times better than standard FR-4 boards.

On Kaboer's production lines in Shenzhen, we commonly see these applications:

LED Lighting: Almost all LED chips over 1 watt use aluminum PCBs. Consider that nearly half the energy in an LED turns into heat. If heat isn't dissipated, brightness drops and lifespan can shrink from 50,000 hours to 10,000.

Power Modules: Especially DC-DC converters and motor drivers. Small MOSFETs and rectifier diodes can easily exceed 100°C during operation—aluminum PCBs are essential.

Automotive Electronics: Particularly for control modules near the engine bay or headlights, where ambient temperatures are high. Aluminum PCBs provide critical extra protection.

High-End Audio: High-power amplifier modules need stable temperatures for stable sound quality.

Cost Considerations

Aluminum PCBs cost about 30–100% more than standard FR-4, depending on size and structure. But they can save you money on heatsinks, fans, and improve reliability and lifespan. Sometimes the total cost favors aluminum.

Design Adjustments

Aluminum is conductive, so insulation during mounting is important. Leave enough space around screw holes to prevent short circuits. Component placement also matters—group heat-generating parts together for the shortest thermal path.

Different Manufacturing Processes

At Kaboer's factory, we handle aluminum PCBs with extra care:

Special drill bits are needed (aluminum can stick to ordinary bits)

V-scoring doesn't work (aluminum won't snap cleanly), so routing is required

Solder temperature control must be precise—aluminum conducts heat so well that uneven heating can cause issues

Not Always Necessary

If your board only gets slightly warm (like a typical control board), FR-4 with a few thermal vias may be enough. Aluminum PCBs are worth the extra cost only when heat is a real problem.

If you're unsure whether you need aluminum PCBs, ask yourself:

Will any components consistently run above 85°C?

Will the product often operate in environments above 40°C?

Is a long product lifespan (e.g., 5+ years) important?

If two answers are "yes," aluminum PCBs deserve serious consideration.

At Kaboer in Shenzhen, we help clients evaluate dozens of designs each month, many switching from standard to aluminum PCBs. We've found that designs which address thermal issues early often proceed more smoothly through testing and production.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..