Date: 2025-12-06

Alright, let's be real. Why do electronics get hot? It's simple physics: electricity flows, resistance kicks in, and heat is born — just like you sweating after running. But those delicate chips and LEDs can't grab a cold drink or crank up the AC. If the heat sticks around, they start to "overheat": performance drops, colors shift, or they just call it quits.

Enter our star of the day: the Aluminum Substrate. Think of it as the "cooling pad" or even the "built-in AC system" for the circuit board world.

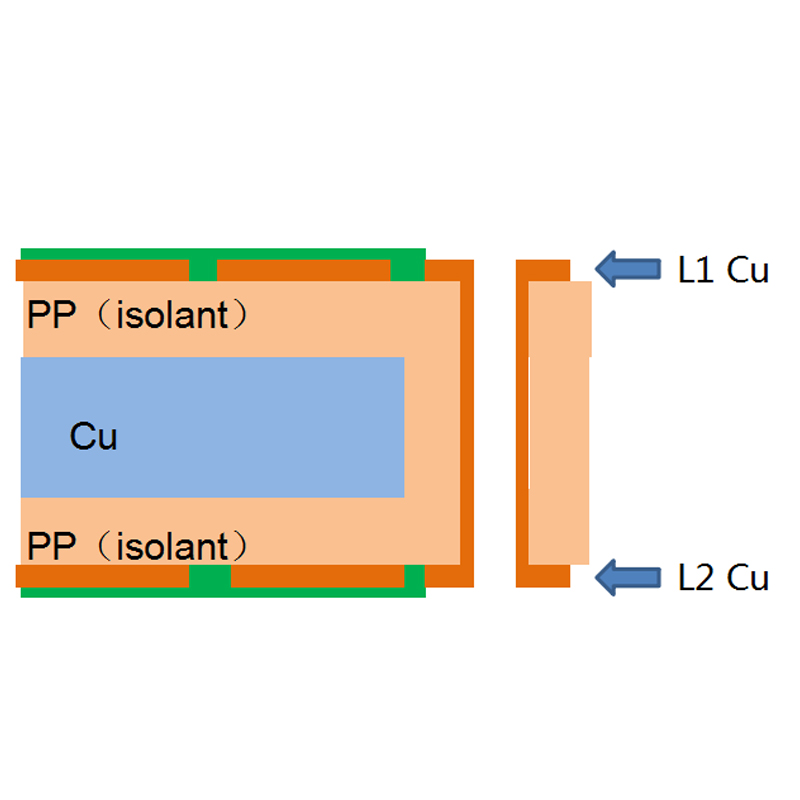

A standard PCB (like FR-4) is made of fiberglass, which is good at insulating — and that's the problem. It traps heat like a blanket. An aluminum substrate is a clever, purpose-built structure, like a sandwich made for maximum heat escape:

The Top Layer (Circuit Layer): The usual setup. Copper traces, components soldered on.

The Middle Layer (The Magic Core): This is the key tech! A thin layer of "thermal glue" (usually a special polymer). It's a double agent: an excellent electrical insulator that prevents shorts, AND a fantastic thermal conductor. Heat passes through this layer faster than you head out on a Friday evening.

The Base Layer (The Heat Sink): A solid, thick slab of aluminum. This is the main event. It acts like a permanent heat spreader, quickly absorbing and dissipating the heat away.

Core principle in one line: Heat = Immediately Conducted + Rapidly Spread. A traditional board is like "having a fever under a duvet," while an aluminum substrate is like "lying on a cool stone slab." The difference is night and day.

Wherever circuits cry "I'm hot!", you'll likely find an aluminum substrate.

LED Lighting: Its "Lifesaver"

High-brightness LED chips get seriously hot. Without an aluminum substrate behind them, sucking away the heat, LEDs would lose brightness ("lumen depreciation") in no time. So, from your home bulbs to streetlights and car headlights, aluminum substrates are the secret to long, bright, and stable LED life.

Power & Automotive Electronics: The "Stabilizer" in Tough Neighborhoods

Power Anything: Fast chargers, PC power supplies, solar inverters. The power-switching chips inside are heat generators that need aluminum substrates to keep cool.

Under the Hood: Battery Management Systems (BMS) and motor controllers in EVs, or LED tail lights in any modern car. The environment is already hot, so managing additional heat is critical. Aluminum substrates work behind the scenes to ensure reliability.

Other "Heat-Sensitive" Elite Applications

Hi-Fi Audio: Power amplifier chips use aluminum substrates to deliver clean, undistorted sound even at high volume.

Telecom Base Stations: Some RF power devices rely on them to stay cool and stable.

Okay, everyone knows aluminum substrates dissipate heat. But like air conditioners, some just blow air, while others are efficient, quiet, and durable. At Kaboer, we aim for the latter.

We Know How to Cool Smarter: It's not just about slapping on some glue and an aluminum plate. The formulation, thickness, and processing of that middle insulating layer are everything. We treat it like a secret recipe, optimizing it for maximum heat transfer and guaranteed electrical insulation.

We Make Boards "Strong and Tough": The aluminum base isn't just for cooling. It gives the board structural muscle — better resistance to vibration and bending than standard boards or brittle ceramics. Perfect for the rough-and-tumble world of automotive and industrial apps.

We Deliver a "Complete Cooling Solution": From understanding your thermal challenge, to design advice, precision manufacturing (you're welcome to visit our own factory to see it live), and rigorous testing (we take thermal resistance metrics seriously), we handle it all. You don't just get a piece of metal; you get a guaranteed thermal management partner.

So, when your next project is getting "hot and bothered," don't just think about adding fans or heatsinks. Think different — start cooling from the ground up.

Let's talk at Kaboer! We'll provide the efficient "cooling pad" your circuit design needs, helping you build a cooler, more reliable, and longer-lasting product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..