Date: 2025-12-06

You know that feeling when you get a new smartphone and it’s somehow faster, smarter, and has a better camera, yet it’s just as thin — or even thinner — than your old one? Or when you hear about the incredible processing power of AI servers and wonder how all that computing force is packed in? There’s a piece of hidden, unsung hero tech inside making a lot of that magic possible: the HDI circuit board.

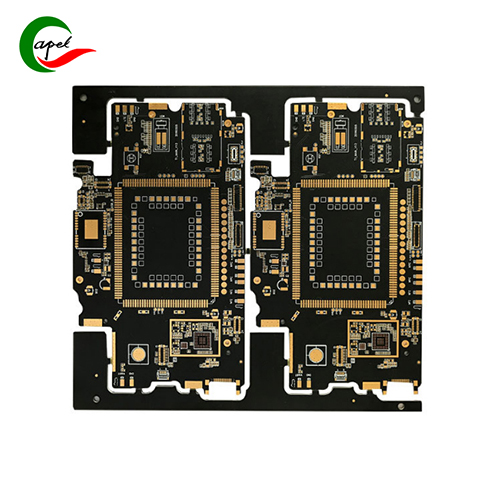

HDI stands for High-Density Interconnect. Let’s break that down without the jargon. Think of a traditional circuit board like the street layout of a small town. The components (chips, capacitors, resistors) are the houses and buildings, and the etched copper lines connecting them are the roads. It works, but there’s only so much you can fit before you run out of space.

An HDI board is like the sophisticated, multi-layered road system of a mega-city. It doesn’t just use surface streets; it employs “micro-vias” — which are essentially incredibly small, laser-drilled tunnels (as tiny as 0.07-0.13mm in diameter) — to create connections between layers vertically, not just horizontally. It also uses advanced techniques to make the “roads” (the circuit lines) much thinner and closer together. This allows engineers to pack more brains and connections into a much smaller space.

This isn't just niche tech for hobbyists. HDI is at the heart of the devices driving our biggest technological leaps. The global HDI market is booming, with its value expected to hit a record $143.4 billion in 2025, growing at a strong 8.7%. Here’s where all that demand is coming from:

The Device in Your Pocket (and on Your Desk): Your smartphone is the classic HDI success story. Over 90% of modern smartphone mainboards use HDI technology to fit powerful processors, advanced modems, and multiple camera sensors into that slim frame. This trend is exploding with AI phones and AI PCs, which need even more processing power in compact forms. In 2025, shipments of AI phones are forecast to jump 73%, directly driving demand for more sophisticated 8-to-12-layer HDI boards.

The Brains of Modern Cars: The shift to electric and autonomous vehicles isn't just about batteries and sensors; it's about more powerful electronics. HDI boards are crucial here for reliability and performance. They are widely used in advanced driver-assistance systems (ADAS), like the cameras and radar that enable automatic emergency braking. As cars become more like computers on wheels, the need for complex 10+ layer HDI in integrated control units is rising fast.

The Engines of the AI Revolution: This is where HDI technology gets truly extreme. AI servers that handle massive datasets require circuit boards that can manage insane speeds and data loads. The modules in these servers often use 18-layer or more HDI boards made with specialized, ultra-low-loss materials to ensure signals don’t degrade. This high-end application represents a major and growing frontier for HDI.

Connecting the World from Above: The race to build global satellite internet constellations, like SpaceX's Starlink, relies on advanced electronics that can survive in space. Low-earth orbit satellites are a major new growth area, requiring high-reliability HDI boards that are both incredibly capable and durable.

Making an HDI circuit board is a world apart from manufacturing a standard PCB. The precision required for those micro-vias and ultra-fine lines is immense. When a design calls for HDI, you’re already working on a high-stakes, high-performance product. You need a manufacturing partner who gets it right the first time, because delays or quality issues can derail your entire product launch.

This is where Kaboer brings its expertise to the table. While we are widely recognized for our leadership in flexible and rigid-flex PCB solutions, our commitment to precision engineering and high-density interconnect technology is core to everything we do.

We understand that HDI is about more than just following a blueprint. It’s about:

Mastering Precision: Utilizing equipment like UV laser drilling machines and LDI (Laser Direct Imaging) systems to achieve the exacting tolerances HDI demands.

Ensuring Absolute Reliability: Implementing a rigorous quality control system. This includes Automated Optical Inspection (AOI) and X-ray inspection to check those hidden micro-vias and ensure every layer is perfectly aligned.

Providing Full Transparency: We operate on a foundation of trust and clarity. Our processes adhere to international standards, and we believe in building confidence through transparency. A key part of this is our open invitation for you to visit our owned and operated factory. See the advanced equipment, meet our engineering team, and understand exactly how your critical components will be built.

In a market projected for strong growth, where the technology is becoming increasingly complex, you need a partner who is invested in the details. You need a manufacturer that combines technical capability with a partnership mindset.

Ready to see how expert HDI manufacturing can power your next-generation product? Let's talk about your requirements. Contact Kaboer today to start a conversation and explore how we can bring your most ambitious electronic designs to life with reliability and precision.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..