Date: 2025-10-08

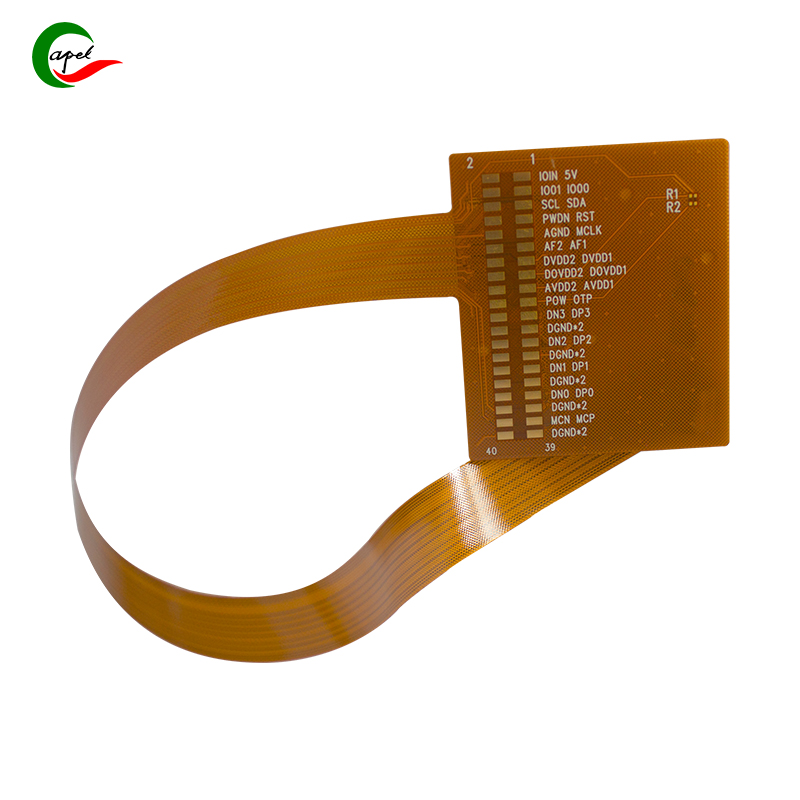

Pop open a smartwatch or a pair of wireless earbuds, and you'll see them: those little gold-plated strips along the edge of a thin, flexible circuit board. In the trade, we call these "gold fingers." And let me be clear—from an engineering standpoint, that thin strip of gold is often the most critical component for long-term reliability.

I've been in the PCB design world for over a decade. I've seen products succeed and I've seen them fail, and more often than not, the root cause of failure boils down to a connection. These gold fingers are the vital interface that links the flexible, bending part of your device to the rest of its brain. So why gold, a notoriously expensive material? Let's cut through the marketing and look at the engineering realities.

Forget the fancy name. Think of gold fingers as the robust, industrial-grade version of the contacts on a credit card strip. They're the exposed, gold-plated terminals on the edge of a flexible PCB (or "flex") designed for one job: to be plugged and unplugged reliably.

In practice, this looks like:

A series of pads, typically 1mm to 3mm wide, running along the PCB's edge.

A construction that's not solid gold, but a copper base (for structure and conductivity) with a microscopically thin layer of "hard gold" electroplated on top. We're talking about 0.5 to 1 micron thin—thinner than a red blood cell.

Their entire purpose is to create a durable, low-resistance electrical path that can survive the real world.

I have this conversation with procurement managers all the time. "Why not use tin or silver? It's cheaper!" My answer is always the same: because cheap connectors create expensive warranty returns. Here’s the breakdown I give them.

The Corrosion Battle is Already Won. This is the number one reason. Flex PCBs live hard lives—nestled against your sweating skin in a fitness band, or inside a factory sensor exposed to humidity and chemical vapors. Gold is noble; it doesn't oxidize or corrode. I've pulled apart failed units where cheaper tin contacts had grown a layer of non-conductive oxide, killing the device. The gold-plated counterparts from the same batch? They were still shining and functional.

It's Built for a Mechanical Lifecycle. A flex cable might be connected during assembly, disconnected for rework, and reconnected multiple times. The "hard gold" alloy we use (typically a gold-cobalt mix) is specifically engineered for this. It can withstand 100+ mating cycles with minimal wear. Tin, on the other hand, is softer and more prone to scraping off. After a dozen insertions, you risk a loose connection—the kind that causes an earbud to cut out when you move your head just right.

Performance You Can Actually Count On. Yes, pure silver has slightly better conductivity on paper. But in the real world, silver tarnishes almost immediately, and that tarnished layer is a terrible conductor. Gold provides a stable, consistent contact surface from day one until the device is retired. For critical data streams, like sending audio signals or precise sensor readings, that consistency is everything. There's no room for "lag" caused by a fluctuating connection.

You won't find gold fingers on every flex PCB—only where the connection is critical and potentially removable.

The Hinge of a Foldable Phone: The flex cable that snakes through the hinge, connecting the two halves of the display, almost always uses gold fingers. It's the only way to ensure a reliable signal after hundreds of thousands of folds.

Mission-Critical Internal Connections: In wireless earbuds, the tiny flex cable connecting the battery or speaker to the main board uses them. In medical devices, like a portable monitor, they're used because the equipment must work reliably even after being wiped down with disinfectants that would destroy other metals.

Plating gold fingers isn't as simple as dipping the board in gold. It's a precise, multi-step electrochemical process that we tightly control.

Nickel is the Unsung Hero. After the copper pads are etched onto the flex, we plate them with a thin layer of nickel. This nickel layer is crucial—it acts as a barrier, preventing copper atoms from migrating up into the gold over time, which would weaken the surface and lead to failure. Skipping this step is a rookie mistake.

The Gold Plating Itself. Only then do we electroplate the actual gold. We use a low-voltage current to deposit that ultra-thin, durable layer of hard gold only onto the contact fingers, a process called selective plating. This keeps costs down while putting the material exactly where it's needed.

Is it perfect? Nothing is.

Cost: Yes, it adds cost. But that cost is often overblown. For a typical flex cable in a consumer device, the gold plating might add only $0.10 to $0.50 to the BoM cost. When you weigh that against a potential 5% failure rate from inferior connectors, the business case becomes a no-brainer.

Design Complexity: It adds two extra manufacturing steps (nickel and gold plating) that require precision and process control. For a one-off hobbyist project, it might be overkill. For mass production of a reliable product, it's standard practice.

In my professional opinion, specifying gold fingers for a flexible PCB connection is one of the easiest reliability upgrades you can make. It's a minor cost that buys a massive amount of insurance against corrosion, wear, and intermittent failure. While other metals might look good on a spreadsheet, gold's proven performance in the harsh reality of daily use makes it the silent, reliable workhorse inside your most sophisticated electronics. Don't let anyone talk you out of it.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..