Date: 2025-10-08

If you’ve used a foldable phone like the Samsung Galaxy Z Fold or Google Pixel Fold, you’ve probably wondered—how does the circuitry inside not break when you flip it open and shut hundreds of times?

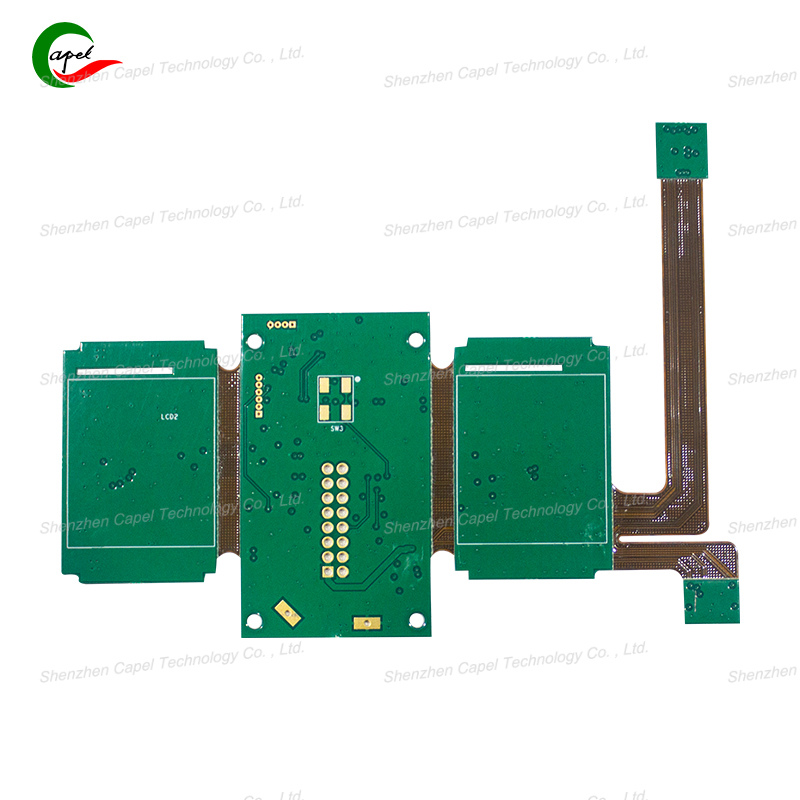

The secret isn’t magic. It’s a type of circuit board called a rigid-flex PCB—part rigid, part flexible. It’s pretty much the only thing that makes foldable screens possible today.

Let me walk you through why that is—and why your phone wouldn’t last a week without it.

Foldable screens have two contradictory needs:

A bendable hinge that survives repeated folding

Stiff areas that can securely hold heavy components like the CPU and battery

Rigid-flex PCBs deliver on both fronts.

1. The Flexible Part Handles the Hinge—Without Fatigue

The hinge is the most stressed part of a foldable. Every time you open or close the device, the PCB inside has to bend along a precise radius—anywhere from 90 to 180 degrees.

Rigid-flex boards use a thin polyimide-based flexible section right under the hinge area. This stuff is incredibly durable. We’re talking 0.05–0.1 mm thin, yet rated for 200,000+ bends—the industry benchmark for a 5-year foldable lifespan.

Real example: The Galaxy Z Fold5 uses a 0.07 mm flexible segment in its hinge. A standard rigid PCB would crack after maybe 20 folds. This one? It’s designed to outlive the phone itself.

2. The Rigid Sections Hold Everything in Place

You can’t mount a processor or battery on a floppy surface. Rigid sections made of FR-4 act like stable islands where all the key components are soldered down.

In the Z Fold5, for instance, the CPU is anchored to a rigid section on the left, while the battery sits in another on the right. No wobble, no drift—just a solid foundation.

Try that on a pure flex board: A 5-gram CPU would make the whole thing sag, eventually breaking solder joints and killing the screen connection.

3. It Saves Space—a Lot

Using separate rigid and flexible boards means you’d need connectors, cables, and brackets to link them—adding thickness and complexity.

A rigid-flex PCB is a single, integrated unit. That eliminates 4–6 extra connectors and their plastic housings, saving up to 1 mm in thickness. That’s huge when you’re trying to make a device that closes completely flat.

The Pixel Fold’s internal layout is 20% thinner thanks to this—helping it achieve that 13.4 mm closed profile.

You might ask: Why not just use a fully flexible or fully rigid board? Let’s break down why those are non-starters.

Pure Flexible PCBs:

Can’t support heavy components—everything shifts

Need extra brackets and fixtures, adding bulk

Their thin copper traces fatigue quickly—most tap out around 50,000–100,000 bends, half what a foldable needs

Pure Rigid PCBs:

Snap on the first fold

Would require two separate boards linked by cables—creating a gap at the hinge and ruining the seamless screen illusion

We don’t just pull these boards off the shelf. They’re heavily customized for the job.

Reinforced Flex Zones:

We add polyimide tape on both sides of the hinge area and use wider copper traces (0.1 mm vs. 0.05 mm) to resist cracking.

Heat-Resistant Coatings:

The rigid sections near hot components like the CPU get special epoxy coatings to prevent warping under temps up to 90°C.

Pre-Scored Bend Lines:

Tiny grooves are laser-etched into the flex zones so the board only bends where it’s supposed to—no stress in the wrong places.

Rigid-flex isn’t perfect—but its downsides are manageable:

Cost: They’re 30–50% pricier than pure flex boards. But when you’re selling a $1,000+ device, it’s a justified premium.

Repairability: If the flex segment fails, the whole board usually needs replacement. But let’s be real—most foldable repairs are already complex and expensive.

Rigid-flex PCBs aren’t just a good fit for foldable screens—they’re pretty much the only viable option right now.

Without them, we’d either have floppy circuits that can’t hold a CPU, or rigid ones that snap in two. It’s this hybrid design that lets you fold, unfold, and use your device like a normal phone—day after day.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..