Last year, my team was designing a new car infotainment system—you know, the big central screen that controls navigation, music, and climate. Our goal was to add three new features: a touch-sensitive volume knob, a rear-seat media controller, and a wireless charging status display. But by week four, our prototype looked like a bird’s nest: rigid PCBs for the screen, separate wires for the knob, and a bulky connector for the rear controller. “We can’t fit this in the dashboard,” our mechanical designer, Zoe, said, holding up the tangled mess. “The wires are crossing, and we have no room to add anything else.”

That’s when we turned to Flexible Printed Circuits (FPCs). Within two weeks, we replaced the rigid PCBs and loose wires with a single FPC that snaked behind the screen, connected the volume knob, and linked to the rear controller—all without crossing wires or wasting space. Even better, when we later decided to add a temperature sensor, we just extended the FPC instead of redesigning the entire layout. “FPCs aren’t just a fix—they’re a way to build for the future,” Zoe said.

This experience taught us why FPCs are now the go-to for central control screens (in cars, smart homes, or even industrial dashboards): traditional rigid PCBs and wires force you into a “fixed” layout with no room to expand. FPCs let you simplify chaos and leave space to grow.

Modern central control screens aren’t just “displays”—they’re hubs for 5+ features (touch, audio, sensors, external controllers). Traditional layouts (rigid PCBs + loose wires) can’t keep up, and here’s why:

Adding features means adding wires—one for the touch panel, one for the volume knob, one for the rear controller. These wires tangle behind the screen, block cooling vents, and break easily when the screen is installed or adjusted.

“We had a test where we had to remove and reinsert the infotainment screen three times (simulating dashboard repairs),” Zoe said. “Two of the wires broke—one for the touch panel, one for the charging display. The screen worked, but half the features didn’t.”

Rigid PCBs are flat and inflexible. If you want to add a new feature (like a temperature sensor), you need to design a whole new PCB—you can’t just “extend” the old one. This adds months to development and makes updates impossible.

Our first infotainment design used a rigid PCB that only fit the screen and basic audio. “When we decided to add the rear-seat controller, we had to make the PCB 20% bigger,” said our electrical engineer, Raj. “But the dashboard didn’t have extra space—we were stuck.”

Central control screens need to grow with user needs (e.g., adding wireless CarPlay later, or a passenger media knob). Traditional layouts use up all available space with their bulky PCBs and wires—there’s nowhere to add new components.

“We measured the dashboard space: 15cm × 10cm,” Raj said. “The rigid PCB + wires took up 14cm × 9cm—no room for anything else. We couldn’t even add a small LED for the charging status.”

FPCs turn a “tangled mess” into a single, clean layout. Here’s how they fix the chaos:

An FPC can have multiple copper traces (10+ if needed) printed on a single thin film. This means one FPC replaces separate wires for the touch panel, volume knob, sensors, and external controllers—no tangles, no crossings.

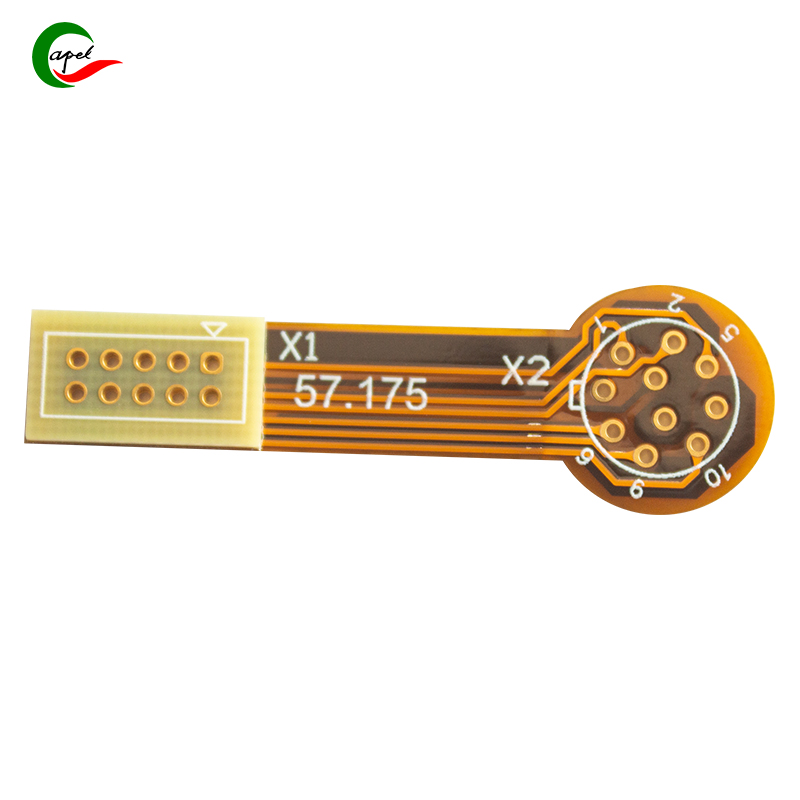

We designed a 0.1mm-thick FPC with 8 traces: 2 for the touch screen, 2 for the volume knob, 2 for the rear controller, and 2 for future features. We routed it along the edge of the dashboard, behind the screen—no wires, no blocks.

“The FPC was so thin, it fit in the 2mm gap between the screen and the dashboard,” Zoe said. “We could even bend it around the climate control vents—something wires never could.”

FPCs bend and curve, so you can route them around obstacles (like vents, screws, or other components) instead of working around them. This frees up space for more features or better cooling.

In our first rigid PCB design, we had to leave a 3cm gap around the climate vents to fit the PCB. With the FPC, we routed it around the vents—freeing up that 3cm gap for a wireless charging status LED. “We went from ‘no room’ to ‘extra room’ just by bending the FPC,” Raj said.

FPCs are one piece, so you install them once—no need to plug in 5+ separate wires. This reduces installation time and eliminates the risk of breaking wires during repairs.

We tested removing and reinserting the screen 10 times with the FPC. None of the features failed—unlike the wire-based prototype, which broke after 3 tries. “Mechanics will love this,” Zoe said. “No more hunting for broken wires behind the dashboard.”

The best part about FPCs? They let you add features later without redesigning everything. Here’s how:

When designing the FPC, you can add 2–3 extra traces (for free, almost) that aren’t used initially. These are “future-proof” for adding new components later.

We added 2 extra traces to our car screen FPC—one for a temperature sensor, one for a passenger media knob. Six months later, when the team decided to add the temperature sensor, we just connected it to the extra trace—no new FPC, no dashboard modifications.

“Adding the sensor took 2 days instead of 2 weeks,” Raj said. “That’s the difference between FPCs and rigid PCBs.”

If you need to add an external feature (like a rear-seat controller or a smart home hub), you can extend the FPC with a small “branch” instead of adding a new wire or PCB.

Instead of using a bulky connector for the rear-seat controller, we added a 10cm “branch” to the main FPC—just a small extension that plugged directly into the controller. It took 5 minutes to design and added no extra bulk.

“The branch fit through the dashboard’s existing wire hole,” Zoe said. “We didn’t have to drill new holes or modify the car’s interior.”

If you upgrade a component (e.g., a better touch panel), you can swap it out without changing the FPC—since the traces are already there. With a rigid PCB, you’d have to redesign the entire board.

We upgraded the car screen’s touch panel from a 5-point to a 10-point sensor. Since the FPC’s touch traces were already compatible, we just plugged in the new panel—no changes to the FPC or dashboard.

“Upgrading took 1 hour,” Raj said. “With a rigid PCB, we’d have to wait 3 weeks for a new board.”

Let’s look at how a smart home company used FPCs to fix their hub screen’s layout and expandability issues. Their initial hub had a rigid PCB that could only connect the screen and a speaker—no room for a motion sensor or a smart light controller.

-

Layout Chaos: 4 wires for the screen, speaker, and power—tangled behind the hub.

-

No Expansion: No room to add a motion sensor or light controller.

-

Installation Issues: Wires broke 30% of the time during setup.

-

FPC for Layout: Replaced wires with a 0.075mm-thick FPC (6 traces: 2 for screen, 2 for speaker, 2 extra for future use).

-

Flexible Routing: Routed the FPC around the hub’s battery, freeing up space for a motion sensor.

-

Future Traces: Used the extra traces to add a smart light controller 3 months later.

-

Layout: No more tangles—installation time cut by 50%.

-

Expandability: Added 2 new features without redesigning the hub.

-

Reliability: Wire breakages dropped from 30% to 0%.

“The FPC turned our ‘basic hub’ into a ‘smart hub that grows with users,’” said the company’s product manager. “Sales increased 40% because customers loved adding new features later.”

Our car infotainment screen journey taught us that central control screens need to be both “clean” (for installation and reliability) and “flexible” (for future features). Traditional rigid PCBs and wires can’t do both—but FPCs can.

Whether it’s a car infotainment system, a smart home hub, or an industrial dashboard, FPCs turn chaos into order and leave the door open to grow. They’re not just a component—they’re a way to build products that work today and get better tomorrow.

Next time you use a central control screen and wonder how it fits so many features in such a small space, chances are there’s an FPC behind it. It’s not visible, but it’s the reason the screen is simple to install, reliable to use, and ready to add new tricks later. And that’s the power of FPCs in central control screens.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.