Last year, my team set out to build a smart ring that tracked heart rate, sleep, and steps. Our goal was simple: a ring no thicker than 3mm (thinner than a dime) that fit most fingers. But by month two, we were stuck. The ring needed a sensor, a microcontroller, a battery, and a wireless chip—and all of them needed to be connected. The rigid PCBs we first tried were impossible to fit, and even the thinnest wires we could find tangled like spaghetti inside the ring’s tiny casing. “We need FPC,” our hardware engineer, Lila, said, slamming a sample flexible circuit on the table. “Nothing else can wire this thing without turning it into a bulky mess.”

She was right. Within a month of switching to Flexible Printed Circuits (FPCs), we had a working prototype. The FPCs snaked around the battery, hugged the sensor, and connected every component without wasting a millimeter of space. That experience taught us why FPCs are the only way to build smart rings: traditional wiring and rigid PCBs can’t handle the “ultra-tiny” constraint—FPCs are designed for it.

In this article, we’ll break down the unique wiring challenges of smart rings, share how FPCs solve them, and outline the key FPC wiring strategies that make tiny smart rings possible.

Smart rings have one non-negotiable rule: they must be small enough to wear comfortably. Most smart rings are 2–3mm thick and 15–20mm in diameter—about the size of a standard wedding band. Traditional wiring (wires, rigid PCBs) can’t fit here—here’s why:

Even the thinnest copper wires (0.1mm diameter) take up space when you need to connect 4–5 components. Worse, they tangle easily inside the ring’s casing, shorting out or breaking when the ring bends (like when you close your hand).

“We tried using 0.1mm wires to connect the sensor and microcontroller,” Lila said. “They tangled so bad, we had to cut open three prototypes just to untangle them. And when we bent the ring, the wires broke—every time.”

Rigid PCBs are flat, inflexible sheets. A smart ring’s casing is curved (to fit your finger), so a rigid PCB either sticks out (making the ring uncomfortable) or can’t connect all components (since they’re spread around the curve).

Our first rigid PCB prototype was a disaster: “We had to mount the battery on one side of the PCB and the sensor on the other,” said our designer, Raj. “The PCB stuck up 1mm above the ring’s surface—you could feel it digging into your finger. We had to scrap it.”

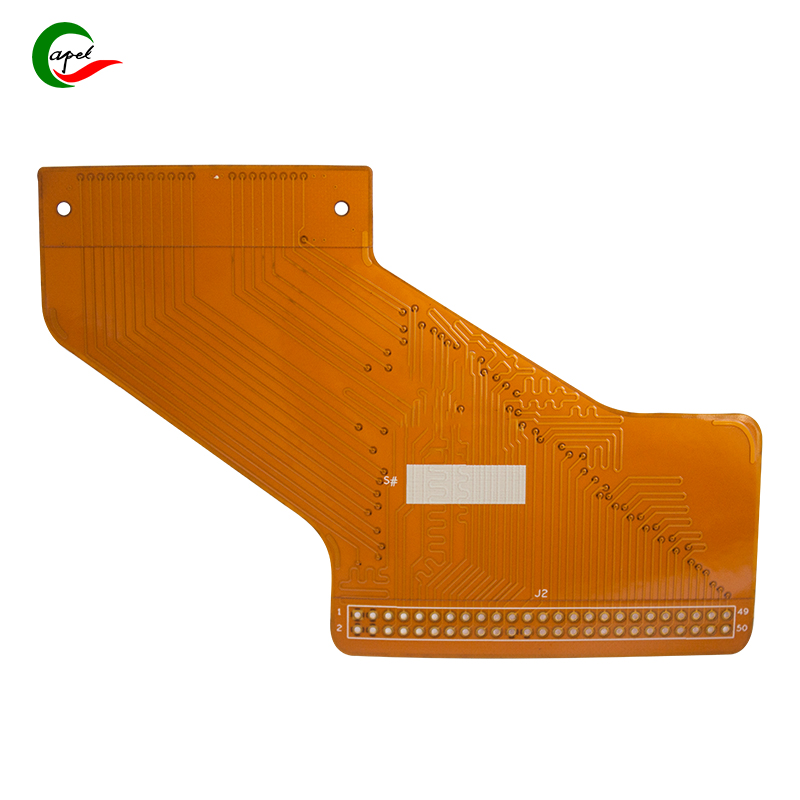

FPCs aren’t just “thin wires on a film”—they’re engineered to fit and function in ultra-tiny, curved spaces. Here’s how they fix the two biggest smart ring wiring problems:

FPCs are made of a thin polyimide (PI) film (0.05–0.1mm thick) with copper traces printed directly on it. This means no loose wires—just a single, flat film that connects all components.

-

No Tangles: The FPC is one piece, so there’s nothing to tangle. You can route it around components without worrying about wires crossing.

-

Minimal Space: A typical FPC for smart rings is 0.075mm thick—thinner than a human hair. It adds almost no bulk to the ring.

-

Flexible Bending: FPCs bend with the ring (when you close your hand) without breaking. The PI film is durable enough to withstand 10,000+ bends—more than enough for daily use.

We replaced the loose wires with a 0.075mm-thick FPC that had 4 copper traces (for power, data, and ground). We routed it around the battery, under the sensor, and to the microcontroller—all in one piece. “No more tangles, no more broken connections,” Lila said. “The FPC bent with the ring like it wasn’t even there.”

FPCs are flexible, so they follow the curve of the smart ring’s casing. This lets you mount components around the ring (e.g., battery on one side, sensor on the other) and connect them with an FPC that hugs the curve.

-

Component Placement Freedom: You can spread components around the ring’s curve (instead of stacking them) to keep the ring thin.

-

No Uncomfortable Bulges: The FPC lies flat against the casing’s inner curve—you can’t feel it when you wear the ring.

-

Efficient Space Use: Curved FPCs use the ring’s “inner circumference” space—area that would be wasted with rigid PCBs.

We mounted the battery on the bottom of the ring (facing your palm) and the sensor on the top (facing up). We routed a curved FPC along the ring’s inner edge to connect them. “The ring stayed 2.8mm thick—under our 3mm target,” Raj said. “You can’t even tell there’s an FPC inside.”

Not all FPC wiring works for smart rings—you need to prioritize space, flexibility, and durability. Below are the three strategies that made our smart ring possible:

Smart rings don’t need complex multi-layer FPCs—single-layer FPCs (one layer of PI with traces on one side) are enough. They’re thinner than multi-layer FPCs and easier to route around tight corners.

-

Thinner: Single-layer FPCs are 0.05–0.075mm thick—multi-layer ones are 0.1mm+ (too thick for smart rings).

-

Simpler Routing: With traces on one side, you don’t have to worry about vias (holes that connect layers) taking up space.

-

Cheaper: Single-layer FPCs cost less than multi-layer ones—critical for small startups.

“We tested both single-layer and two-layer FPCs,” Lila said. “The two-layer one added 0.03mm to the ring’s thickness—enough to make it uncomfortable. Single-layer was perfect.”

The smart ring’s inner edge (the part that touches your finger) is the most underused space—use it for FPC routing. Traces along the inner edge don’t interfere with components (mounted on the outer edge) and stay hidden.

-

Follow the Curve: Keep traces parallel to the ring’s curve—avoid sharp bends (which can break the FPC).

-

Minimize Trace Width: Use 0.05mm-wide traces (the thinnest reliable size) to save space. You only need thicker traces for power (0.1mm), not data.

-

Space Traces Evenly: Leave 0.05mm between traces to avoid short circuits—this is tight, but doable with FPC manufacturing.

Our ring’s FPC had 4 traces: 2 data traces (0.05mm wide), 1 power trace (0.1mm wide), and 1 ground trace (0.1mm wide). We routed them along the inner edge, spaced 0.05mm apart. “It fit perfectly—there was still room for the battery and sensor,” Raj said.

To save more space, mount small components (like resistors, capacitors, or even tiny sensors) directly on the FPC—instead of using separate PCBs for them. This eliminates the need for extra wires to connect components.

-

Passive Components: Small resistors (0402 size, 0.4mm × 0.2mm) and capacitors fit easily on FPCs.

-

Tiny Sensors: Some heart rate sensors (like the Maxim MAX30102) are small enough to mount on FPCs.

-

Connectors: Use ultra-small connectors (0.5mm pitch) on the FPC to connect larger components (like the microcontroller).

“We integrated two 0402 resistors and a capacitor directly on the FPC,” Lila said. “This saved us from using a separate small PCB for them—we freed up 0.5mm of space, which let us use a slightly bigger battery.”

Let’s look at how a small startup used FPCs to launch their smart ring. They were struggling with a 3.5mm-thick prototype that was too uncomfortable to wear. Here’s how FPCs fixed it:

-

Too Thick: Rigid PCB + wires made the ring 3.5mm thick—users complained it felt “bulky.”

-

Broken Connections: Wires broke when the ring bent, leading to 20% failure rate in testing.

-

No Space for Battery: The rigid PCB took up so much space, the battery only lasted 12 hours.

-

Switch to Single-Layer FPC: 0.075mm-thick FPC with 4 traces (routed along the inner edge).

-

Integrate Components: Mounted resistors and a small sensor directly on the FPC.

-

Curve the FPC: Routed the FPC around the ring to connect the battery (bottom) and microcontroller (top).

-

Thickness: Dropped to 2.7mm—users said it “felt like a normal ring.”

-

Durability: Failure rate fell to 2% (no more broken wires).

-

Battery Life: Jumped to 24 hours (more space for a bigger battery).

“The FPC wasn’t just a wiring fix—it made our product wearable,” said the startup’s CEO. “We went from 10 pre-orders to 500 in a month.”

Our smart ring journey taught us that tiny devices need tiny, flexible wiring—and FPCs are the only way to do it. Traditional wires and rigid PCBs force you to choose between size and functionality, but FPCs let you have both: a ring that’s comfortable to wear and packed with features.

As smart rings get even smaller (some startups are targeting 2mm thickness) and more powerful (adding blood oxygen or temperature tracking), FPCs will become even more critical. They’re the “invisible” component that makes it all possible—you can’t see them, but you’d notice if they weren’t there.

Next time you try on a smart ring and wonder how all those features fit in such a tiny space, remember: there’s an FPC inside, wiring everything together. It’s not glamorous, but it’s why you can wear a powerful device on your finger—without even noticing it’s there.