Date: 2025-12-16

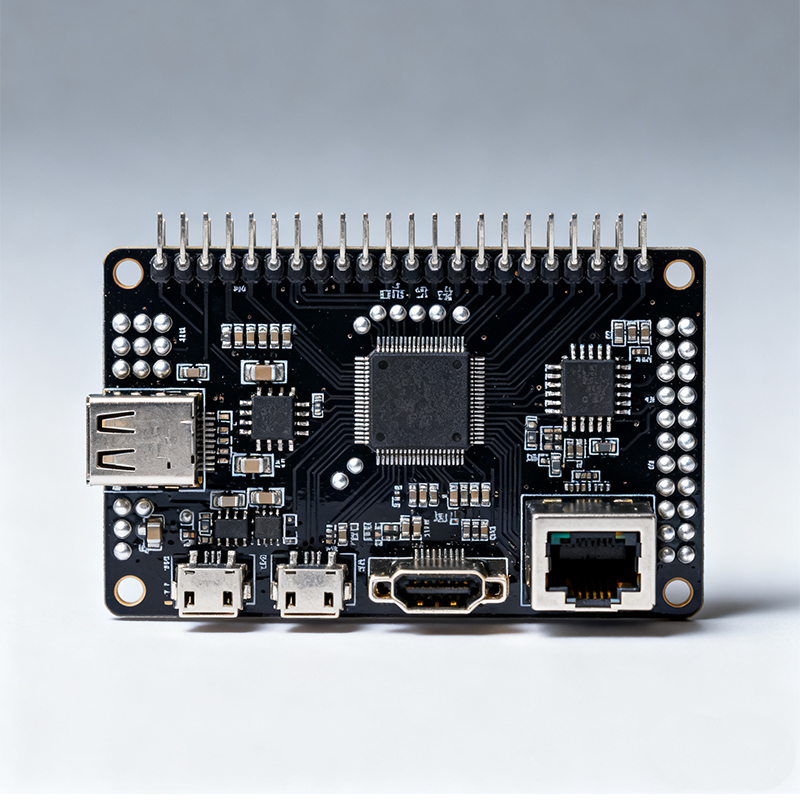

In the world of electronics, aesthetics often follow function. While the iconic green solder mask dominates, you've likely noticed a sophisticated alternative gaining ground: the black circuit board. This isn't merely a stylistic choice for a "stealth" look; it's a deliberate design and manufacturing decision with tangible technical and commercial benefits. Let's demystify what a black circuit board is, why it matters, and what it takes to manufacture it well.

At its core, a black circuit board is a standard printed circuit board (PCB) that uses black solder mask ink instead of the traditional green. The solder mask is the polymer layer applied over the copper traces to prevent accidental short circuits, protect against oxidation, and provide insulation. The color comes from the pigments within this ink.

It's crucial to distinguish this from the base material (substrate). The substrate, typically FR-4 fiberglass, remains its natural color (often a tan or yellow-brown) beneath the layers. The "black" refers specifically to the topmost, visible coating.

Choosing black isn't just about looks; it serves several key purposes:

1. Enhanced Aesthetics and Premium Branding

This is the most immediate benefit. Black PCBs convey a sense of quality, luxury, and high technology. They are a hallmark of premium consumer electronics—think high-end graphics cards, flagship smartphones, premium audio equipment, and gaming peripherals. The uniform, dark background makes gold or silver finishes (like ENIG or immersion silver) on components and connectors "pop," creating a visually striking and coherent product interior.

2. Improved Contrast for Assembly and Inspection

During the assembly process, white silkscreen (the component labels and logos printed on the board) provides exceptional contrast against a black background. This can significantly improve readability for technicians during manual assembly, rework, and debugging phases, potentially reducing human error.

3. Reduced Light Reflectance and Interference

For devices containing sensitive optical sensors (e.g., cameras, ambient light sensors, certain medical devices) or those operating in high-light environments, a matte black solder mask helps minimize internal light reflection and scattering. This reduces optical noise ("crosstalk") and can improve the accuracy and performance of the sensors.

4. Masking Minor Substrate Imperfections

The dark, opaque nature of black solder mask is excellent at hiding the internal fiberglass weave pattern and minor substrate variations that might be visible under a translucent green mask. This results in a more consistently uniform and flawless appearance across the entire board surface.

Achieving a high-quality black PCB requires precise manufacturing control. Not all factories produce them equally well.

Silkscreen Legibility: As mentioned, white ink is standard. The print quality must be sharp and opaque to ensure legibility. Some manufacturers offer very fine gray or even translucent silkscreen for a more subtle look, but this can compromise readability.

Thermal Management: Black absorbs more infrared radiation during the reflow soldering process. While modern inks are formulated to handle this, the thermal profile in the oven may need slight adjustment compared to lighter colors to prevent potential issues like delamination.

Inspection Difficulty: Automated Optical Inspection (AOI) systems can find it more challenging to identify and inspect copper traces and solder joints on a high-contrast, non-reflective black surface. Factories need properly calibrated, high-resolution AOI cameras with optimized lighting to ensure defect detection rates remain as high as with green boards.

Potential for "Halos": If the solder mask alignment (registration) is not perfect during application, a tiny sliver of the underlying copper or substrate may be exposed around pads. On a black board, these can appear as subtle "halos" or outlines. Tight process control is needed to minimize this.

At Kaboer, based in Shenzhen, China, we understand that details matter. Manufacturing a premium black circuit board is a test of a factory's process consistency and quality control.

Our own manufacturing facilities are equipped to handle the specific requirements of black solder mask and other advanced finishes. We pay close attention to the entire process—from solder mask viscosity and application thickness to silkscreen precision and thermal profiling during assembly—to ensure that your black PCBs are not only visually impressive but also electrically reliable and performant.

Whether your project calls for the classic green or a sophisticated black finish, we have the expertise to deliver boards that meet your highest standards for both form and function.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..