Date: 2025-12-31

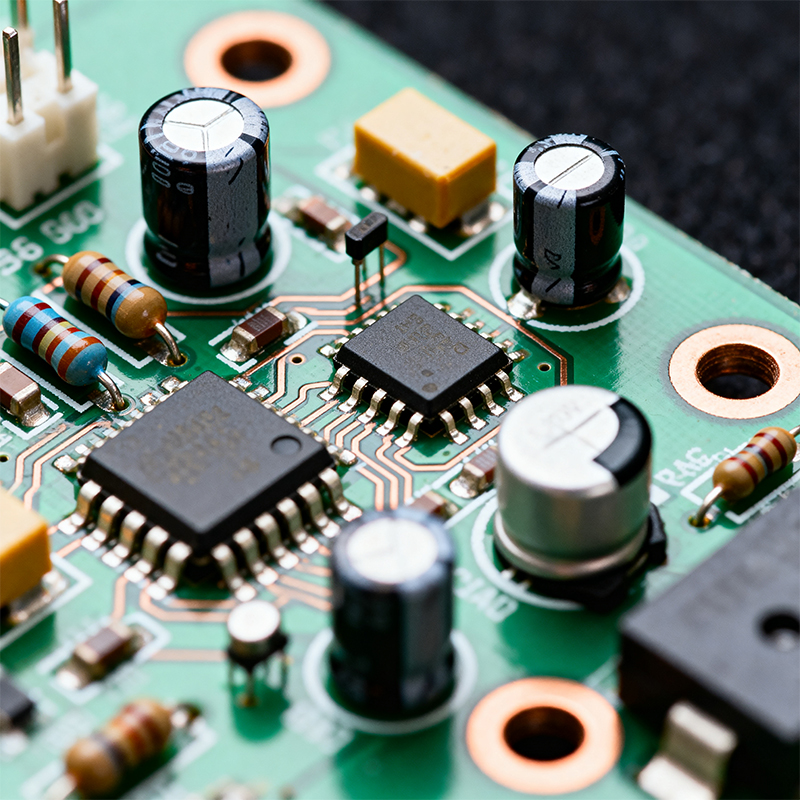

Every time you pick up your smartphone or start your laptop, you're interacting with a miniature electronic world. At the heart of this world are the tiny parts soldered onto that green board – what we call circuit board electronic components.

Think of a finished circuit board as a symphony orchestra. The PCB is the stage and the music stands, but the electronic components on it are the musicians. Resistors, capacitors, chips... each "musician" has a unique role. They must work in concert to play the symphony—that is, to make the device function.

Resistors: Act like valves in a water pipe, controlling the amount of current flow. Without them, a surge could fry delicate chips.

Capacitors: Like tiny power banks, they charge and discharge rapidly to filter noise and stabilize voltage, ensuring smooth power delivery. They help your phone run without a hiccup.

Integrated Circuits (ICs/Chips): This is the conductor and the virtuoso of the orchestra. A single chip packs millions or billions of transistors, forming the intelligent core of your device.

Inductors: Think of them as "flywheels" for current, resisting sudden changes. They're crucial in power circuits.

Diodes: They act as "check valves" for electricity, allowing current to flow in one direction only. An LED is simply a diode that emits light.

Feel overwhelmed by the terms? You're not alone. Most engineers keep a cheat sheet handy. The key isn't memorization; it's understanding how they work together and—more critically—how to make the right choices for your product.

For many hardware startups and overseas brands, finalizing a perfect schematic is just the opening act. The real drama often unfolds later:

The "Paper Design" Trap: That perfect component in your design software might be discontinued, have a skyrocketing price, or a 6-month lead time in the real world. This can derail your entire project timeline.

The "Counterfeit" Risk: The component market has fake and substandard parts. A cheap, dubious chip can cause an entire product batch to fail in the field. The cost of recalls and brand damage can be catastrophic.

The Design-Manufacturing Gap: A layout that looks perfect on screen might have components placed too close for automated soldering. This forces reliance on expensive, inconsistent manual labor, killing your yield rate.

Let's be frank: half the secret to hardware success lies in supply chain and design-for-manufacturability. This is why more companies are choosing to partner deeply with a reliable manufacturer, not just emailing drawings to a factory.

A truly professional PCBA partner should engage with your design early to help you avoid those pitfalls. Here at Kaboer, running our own factory in Shenzhen has taught us what makes projects succeed. Our approach is built on that experience:

We Start with a BOM Review, Not Just a Quote: When we get your Bill of Materials, our engineers first perform a "health check." We flag parts with supply risks, suggest better alternatives for cost or performance, and identify packages that are hard for volume production. The goal is to eliminate potential failures before production even begins.

We Turn Supply Chain Access Into Your Advantage: Being in Shenzhen means we're on the same street as component manufacturers and top-tier distributors. This isn't just about buying parts; it's about market intelligence and risk mitigation. We get early warnings on shortages and can leverage our channels to secure critical parts, making your project timeline more predictable.

DFM Analysis Isn't Optional; It's Essential: We analyze your PCB design files with specialized software to generate a detailed report. It might say, "These two components are too close, risking solder bridging," or "This chip's thermal pad design needs optimization to prevent cold solder." This early feedback is often more valuable than the production itself, saving you significant time and revision costs.

Quality Control Under the "Microscope": Beyond standard AOI, for components like BGAs where solder joints are hidden, we use X-ray inspection. It's like getting a "chest X-ray" for your board, ensuring every single solder joint under the chip is perfect. Quality isn't just inspected in; it's built in through processes like this.

In the end, the world of circuit board electronic components is the bridge between your idea and a tangible product. Its complexity lies less in the technology and more in balancing a global supply chain, precise manufacturing, and tight market windows.

Every successful hardware product is supported by a team that understands not just assembly, but also design and the supply chain. If you're facing challenges with component selection, supply stability, or production yield, let's talk. Kaboer's team and factory in Shenzhen are here to be the most reliable building block in your hardware journey.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..