Date: 2025-12-29

Printed Circuit Board Assembly (PCBA) is the comprehensive, multi-stage industrial process of populating a bare printed circuit board (PCB) with electronic components and soldering them in place to create a functional electronic circuit. It is the critical transformation phase where a passive substrate becomes the active “brain” or “nervous system” of virtually every modern electronic device.

Understanding PCBA is essential for any electronics manufacturer, as it represents the point where design intent meets manufacturing reality. This guide delves into the what, why, and how of professional PCBA, providing a foundation for making informed decisions about your production.

The distinction is fundamental:

PCB (Printed Circuit Board): The physical, unpopulated board. It is the insulating substrate (like FR-4) with laminated copper traces that form the conductive pathways. A PCB is inert; it has structure but no function.

PCBA (Printed Circuit Board Assembly): The fully populated and functional assembly. It is the finished product after all required components (resistors, ICs, connectors, etc.) have been precisely mounted and soldered onto the PCB.

In simple terms: PCB + Components + Assembly Process = PCBA.

Modern electronics demand precision, reliability, and scalability that can only be achieved through professional assembly:

Enables Miniaturization & Complexity: Automated machines can place microscopic components (down to 01005 size) with high density, enabling advanced features in small form factors.

Ensures Quality & Reliability: Controlled processes like reflow soldering and automated inspection create consistent, robust electrical connections that withstand thermal cycling, vibration, and long-term use.

Provides Scalability & Cost-Effectiveness: Automated SMT lines can assemble thousands of components per hour, dramatically reducing unit labor costs and enabling viable mass production.

Mitigates Supply Chain Risk: Professional manufacturers have the expertise and networks to source, manage, and qualify components globally, preventing production stalls.

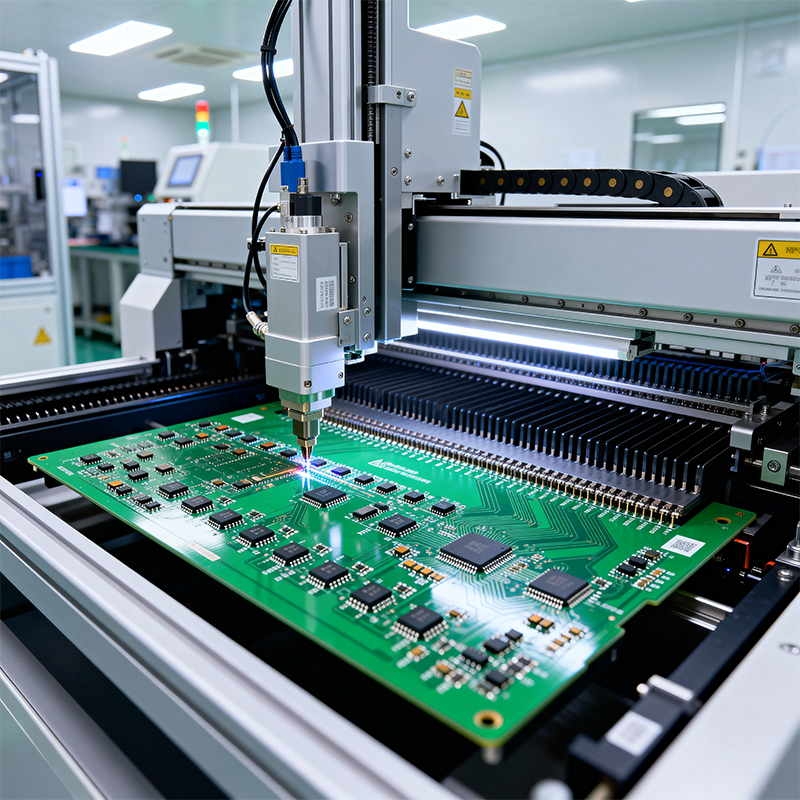

A state-of-the-art PCBA line is a symphony of automated and controlled processes.

Phase 1: Pre-Production & Solder Paste Application

Design for Manufacturability (DFM) Review: The manufacturer analyzes your design files (Gerbers, BOM, layout) to identify potential assembly issues, suggesting optimizations for yield, cost, and reliability.

Solder Paste Printing: A laser-cut stainless steel stencil is aligned over the PCB. Solder paste (a mix of tiny solder spheres and flux) is precisely deposited onto the component pads. 3D Solder Paste Inspection (SPI) is often used here to verify paste volume and alignment.

Phase 2: Automated Component Placement

High-Speed SMT Placement: A pick-and-place machine uses programmed nozzles and vision systems to pick Surface Mount Devices (SMDs) from reels, sticks, or trays and place them onto the solder-paste-coated pads with micron-level accuracy. Modern lines combine ultra-fast “chip shooters” for passives with flexible placers for complex ICs.

Phase 3: Soldering & Secondary Assembly

Reflow Soldering: The populated board travels through a multi-zone reflow oven with a carefully profiled thermal curve. The paste melts, forming permanent metallurgical solder joints, and then solidifies upon cooling.

Through-Hole Assembly: For boards with leaded components, processes like selective soldering or wave soldering are employed after SMT assembly.

Phase 4: Inspection, Testing, and Final Processing

Automated Optical Inspection (AOI): Cameras scan the board from multiple angles to detect defects like missing, misaligned, or tombstoned components, and solder bridges.

X-Ray Inspection: Essential for examining hidden solder joints under Ball Grid Array (BGA) packages or within complex assemblies.

Electrical Testing: This ranges from Flying Probe and In-Circuit Test (ICT) for connectivity verification to full Functional Test (FCT), where the PCBA is powered and tested in a simulated operational environment.

Conformal Coating & Final Assembly: A protective polymer coating may be applied for environmental protection. The PCBA may then be integrated into its enclosure or with other subsystems (Box Build).

Selecting the right manufacturer is a strategic decision. Key evaluation criteria include:

Technical Capability & Technology Stack: Can they handle your component mix (e.g., fine-pitch BGAs, 01005 passives)? Do they have SPI, AOI, X-Ray, and advanced testing facilities?

Quality Certifications & Standards: Look for adherence to ISO 9001 and relevant industry-specific standards (e.g., IATF 16949 for automotive, ISO 13485 for medical). Workmanship should follow IPC-A-610 Class 2/3 guidelines.

Supply Chain Management & Flexibility: Do they have robust systems for component sourcing, obsolescence management, and mitigating supply chain disruptions? Can they support both Turnkey (full procurement) and Consignment models?

Engineering Support & Communication: The best partners offer proactive DFM feedback and act as an extension of your engineering team, with clear and responsive communication channels.

Navigating the complexities of modern PCBA requires a partner that offers more than just assembly capacity—it requires transparency, control, and deep technical collaboration. For global brands seeking to de-risk production and accelerate innovation, the traditional multi-vendor outsourcing model often introduces complexity and communication gaps.

At Kaboer, we offer a fundamentally different approach. We are a PCBA specialist that operates our own, fully integrated manufacturing facility in Shenzhen, China. This ownership model is not merely an operational detail; it is the core of the value we deliver to our clients.

The Kaboer Advantage: Control, Clarity, and Partnership

Vertical Integration for Uncompromised Quality: By controlling the entire production process under one roof—from SMT programming to final test—we eliminate the variability and accountability issues inherent in using subcontractors. Our in-line process controls (SPI, AOI) feed data back in real-time for adjustment, not just for final inspection, resulting in superior first-pass yield and consistent quality.

Engineering-Led Collaboration from Day One: Our team engages at the design review stage with a partnership mindset. We provide detailed, actionable DFM/DFT analysis focused on optimizing your design for manufacturability, test coverage, and long-term reliability. We help you avoid costly revisions and build a more robust product from the start.

The Shenzhen Ecosystem, Optimized for Your Agility: Our location in the global electronics epicenter provides unparalleled access to one of the world’s most dynamic component supply chains. This allows for rapid prototyping, agile response to component shortages, and efficient sourcing, all managed by our expert procurement team to keep your project on schedule and within budget.

Transparent Communication and Scalable Operations: You communicate directly with our engineering and production management. This clarity accelerates decision-making and problem-solving. Whether you need a 25-unit NPI run or are scaling to volume production of 25,000+ units monthly, our dedicated production cells ensure a seamless transition without the need to re-qualify a new factory.

A True Extension of Your Manufacturing Team: We view our role as a strategic partner. Our goal is to provide you with the control and peace of mind that comes with an in-house facility, combined with the expertise, scale, and cost advantages of a specialized partner in Asia.

Partner with Kaboer to transform your PCBA production from a complex supply chain challenge into a streamlined, reliable, and collaborative advantage.

Q1: What is the difference between Turnkey and Consignment assembly?

A: In Turnkey assembly, the PCBA manufacturer procures all components and materials on your behalf, managing the entire supply chain. In Consignment, you (the customer) provide all the components, and the manufacturer charges for the labor and process of assembly. Turnkey offers a single point of responsibility, while Consignment can offer more direct cost control on parts.

Q2: What files do I need to provide to get a PCBA quote?

A: The essential file package includes: Gerber files (for PCB fabrication), a complete Bill of Materials (BOM) with Manufacturer Part Numbers, Pick-and-Place files (centroid data), and Assembly drawings with any special instructions.

Q3: How do you ensure quality for high-reliability applications (e.g., automotive, medical)?

A: Beyond standard IPC checks, we implement application-specific protocols. This includes enhanced traceability (lot/batch coding), stricter process controls with Statistical Process Control (SPC), employment of dedicated high-reliability solder pastes and materials, and execution of tailored reliability testing such as extended thermal cycling or vibration testing.

Q4: What is your typical lead time for prototype vs. production runs?

A: Prototype/NPI lead times typically range from 10-15 working days after design approval, depending on component availability. For established volume production, cycle times can be as short as 2-3 weeks from order confirmation to shipment, as the processes and supply chain are fully optimized.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..