Date: 2025-12-31

What Is Electronics Assembly?

At its core, electronics assembly is the process of putting together all the individual components that make an electronic device work. If you imagine a device like a smartphone as a complex puzzle, electronics assembly is the act of placing every single piece—from the tiniest chip to the largest battery—into its correct spot and securing it so the whole picture functions perfectly.

It transforms a design on a computer into a physical, working product you can hold in your hand. This process is foundational to creating everything from simple remote controls to advanced medical equipment and satellites.

The Main Types of Electronics Assembly

There are two primary methods used to attach components to a circuit board, each suited for different needs:

Surface Mount Technology (SMT): This is the modern, dominant method. It involves placing very small components (known as Surface Mount Devices or SMDs) directly onto the surface of a printed circuit board (PCB). Think of components like tiny chips, resistors, and capacitors that look like little black rectangles or cylinders. They are placed by ultra-precise robotic machines and then soldered in place by passing the board through a special oven. SMT allows for extremely small, dense, and high-performance devices.

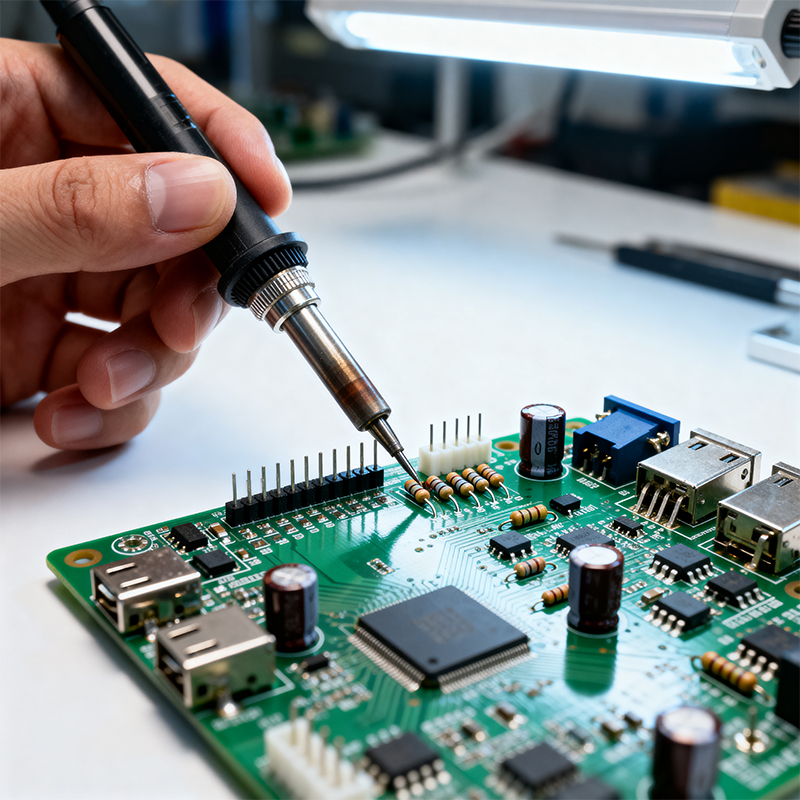

Through-Hole Technology (THT): This is the older, more traditional method. Components have long wire leads that are inserted into drilled holes on the PCB and soldered on the opposite side. These components, like larger capacitors or connectors, are generally bigger and more robust. THT creates very strong mechanical bonds, so it's often used for parts that will endure physical stress, like a power plug that gets frequently connected and disconnected.

Most modern electronics use a combination of both, called a mixed-technology assembly. The small, complex chips are placed with SMT for density, while the sturdy connectors and large transformers are added with THT for strength.

The Key Stages in the Assembly Process

Electronics assembly isn't just one step; it's a carefully orchestrated sequence:

Solder Paste Application: For SMT, a sticky paste of solder and flux (a cleaning agent) is first printed onto the PCB where components will sit. It acts like a temporary, conductive glue.

Component Placement: Robotic "pick-and-place" machines, guided by the digital design files, pick up components from reels and place them onto the solder paste with incredible speed and accuracy.

Soldering: The board travels through a reflow oven. The heat melts the solder paste, which then cools and solidifies, forming a permanent electrical and mechanical connection.

Inspection and Testing: This is a critical quality check. Machines like Automated Optical Inspection (AOI) systems use cameras to scan boards for missing or misaligned parts. Further electrical tests check if the assembled board powers on and functions correctly.

Final Assembly (Box Build): This is where the assembled PCB—the "brains" of the device—is integrated into the final product. It involves installing it into the plastic or metal case, connecting wires, adding screens, batteries, and buttons until the product is fully complete.

Final Functional Test: The finished product undergoes a last round of testing to ensure everything works as intended before it's packaged for shipment.

Industry Trends and Considerations

The field is constantly evolving. Key trends include:

Miniaturization: Devices keep getting smaller, pushing assembly precision to its limits.

Automation: Factories are becoming more automated with robotics and AI-driven inspection to ensure consistency and reduce errors.

Supply Chain Complexity: Modern electronics can contain components from dozens of countries, making the logistics of getting the right part to the factory at the right time a major challenge.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..