Date: 2025-12-17

When you hear "circuit card assembly," what comes to mind? For many outside the industry, it might sound like technical jargon. But for engineers and procurement specialists in aerospace, defense, medical, and industrial automation, it's a term that signifies the gold standard in reliability and precision manufacturing. It’s the meticulous process that transforms a bare circuit board into the trusted, functional heart of the most demanding electronic systems on the planet.

For global manufacturers who cannot afford failure, understanding what true circuit card assembly entails—and what differentiates it from standard board stuffing—is critical for specifying, sourcing, and ensuring the longevity of their products.

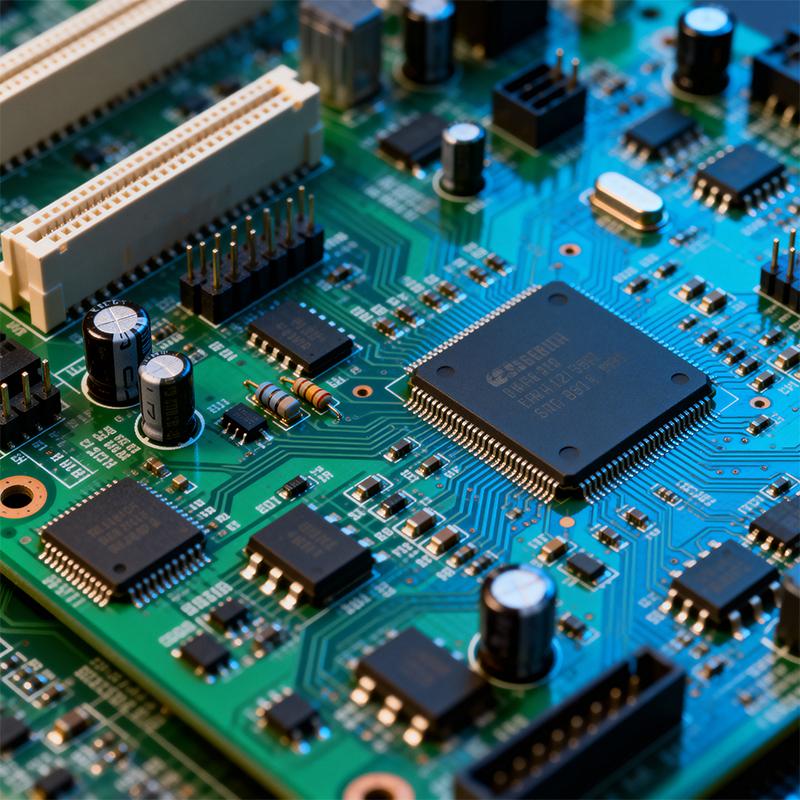

Circuit Card Assembly (CCA) is essentially synonymous with Printed Circuit Board Assembly (PCBA). It describes the comprehensive, end-to-end process of populating a bare printed circuit board (PCB) with all its electronic components and interconnecting them through soldering to create a fully functional circuit card or module.

The term "circuit card" often implies a focus on ruggedness, high reliability, and formal process control, particularly in industries where failure is not an option. While the core steps are similar to commercial PCBA, the mindset, standards, and scrutiny applied are frequently on another level.

Precision Component Placement: Utilizing advanced pick-and-place machines capable of handling a wide range of components, from tiny 01005 passives to large, odd-form connectors and heatsinks, all with micron-level accuracy.

Advanced Soldering Techniques: Employing a mix of reflow soldering, selective soldering, and sometimes hand soldering for delicate or high-reliability connections, all governed by strict process controls and detailed workmanship standards (like IPC-A-610 Class 2 or 3).

Conformal Coating & Potting: Applying specialized protective coatings to shield the assembly from environmental hazards such as moisture, dust, chemicals, and vibration—a common requirement for CCAs in harsh environments.

Rigorous, Multi-Stage Testing & Inspection: This is where CCA often diverges significantly. It involves a gauntlet of verification:

Automated Optical Inspection (AOI) for solder joint quality.

X-Ray Inspection for hidden solder joints (e.g., under BGAs).

In-Circuit Test (ICT) to verify correct component value and placement.

Functional Test (FCT) to ensure the card performs its intended operation under simulated real-world conditions.

Environmental Stress Screening (ESS), such as thermal cycling and burn-in, to weed out early-life failures.

Why is there such an emphasis on this process? Because a well-executed CCA is the single biggest determinant of an electronic system's performance, longevity, and total cost of ownership.

It Embodies Reliability: In fields like aviation or medical implants, a circuit card isn't just a part; it's a life-critical component. The assembly process directly builds in (or can compromise) the decades of failure-free operation required.

It Enables Complex Functionality: Modern systems rely on CCAs to integrate incredible complexity into a single, manageable module. From flight control computers to MRI scanner boards, they consolidate processing, power, and signal I/O.

It Reduces System-Level Risk: By delivering a fully validated and tested subsystem, CCA mitigates risk at the final system integration stage. Troubleshooting is confined to a single, well-documented card rather than a web of interconnected, untested parts.

It Ensures Long-Term Support: For industrial or military systems with lifespans of 20+ years, having a trusted CCA partner ensures the repeatability and traceability needed for future repairs, replacements, and upgrades.

Aerospace & Defense: Avionics, flight controls, communication systems, radar.

Medical Devices: Diagnostic imaging (CT, MRI), patient monitors, surgical robots, life-support systems.

Industrial Automation & Control: Programmable Logic Controllers (PLCs), motor drives, robotics, process control systems.

Telecommunications & Networking: High-availability server and networking hardware, base station cards.

At Kaboer, based in the global manufacturing hub of Shenzhen, we understand that the label "circuit card assembly" carries a weight of expectation. It demands a factory that is more than just automated; it must be disciplined, documented, and deeply quality-conscious.

Our focus extends beyond simple throughput. We are equipped to meet the elevated standards that complex, high-reliability CCAs require. This includes investment in the right inspection technology, adherence to stringent process controls, and a team that understands the importance of traceability and documentation from component sourcing through to final test. For manufacturers who view their circuit cards as the non-negotiable core of their systems, partnering with an assembler who shares that philosophy is the first critical step toward success.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..