Date: 2026-02-05

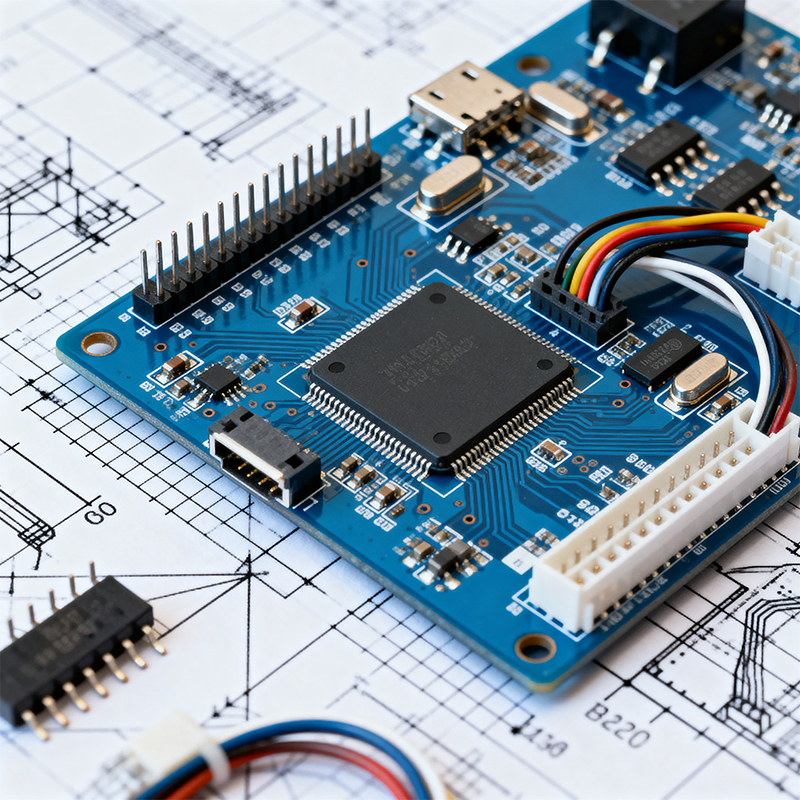

Imagine building a complex LEGO castle - you have a pile of bricks in various shapes, colors, and functions that need to be combined in a specific order and position to create the final structure you want. Electronic component assembly is essentially this process, except the bricks become resistors, capacitors, chips, and other electronic components, and the castle becomes a working circuit board or electronic device.

Simply put, component assembly is the process of precisely mounting and connecting individual electronic components onto a circuit board to form a functional electronic module or complete product. From the motherboard in your smartphone to the control units in your car, nearly every modern electronic product requires this crucial manufacturing step.

Through-hole technology is like threading a needle: components have long leads that pass through holes in the circuit board, then are soldered in place on the opposite side. This method is more traditional but remains important, especially for connections that need to withstand significant mechanical stress or heat.

The characteristic of through-hole assembly is exceptionally strong connections, since the leads pass completely through the board. You'll find these types of connections in power adapters, industrial control boards, or any device that needs to withstand pulling, compression, or vibration.

Its main steps include:

Inserting component leads into corresponding holes in the circuit board

Flipping the board so leads face upward

Securing leads through wave soldering or manual soldering

Surface mount technology is the mainstream of modern electronic assembly. It's more like "laying tiles": components don't have long leads but instead have flat metal tabs (called "pins" or "pads") that sit directly on corresponding pads on the board's surface, then are secured through reflow soldering.

Advantages of SMT include:

Components can be extremely small, fitting modern electronics miniaturization trends

Higher assembly density - more functionality per unit area

High automation suitable for mass production

Generally lower cost with higher production efficiency

Today over 90% of electronic assembly uses SMT technology. Your smartphones, laptops, and smartwatches rely almost exclusively on this method.

A typical SMT component assembly process can be divided into several key stages:

1. Solder Paste Printing

This is the first and one of the most critical steps in the assembly process. Solder paste is a viscous mixture of microscopic solder balls and flux. Through a thin stencil (with holes corresponding to the circuit board pads), solder paste is precisely "printed" onto locations where soldering is needed on the board. It's somewhat like using a stencil to sprinkle powdered sugar on cookies.

2. Component Placement

The pick-and-place machine acts like a high-speed, precise robotic hand, picking various components from feeders and accurately placing them onto the solder paste-covered pads. Modern placement machines are incredibly fast - some high-end models can place hundreds of thousands of components per second with micron-level precision.

3. Reflow Soldering

The board then enters a reflow oven, undergoing a precisely controlled temperature profile. The solder paste melts at high temperature, then solidifies upon cooling, forming secure electrical and mechanical connections. You can think of this process as "electronic baking."

4. Inspection and Testing

After assembly, the board must undergo rigorous inspection. Automated optical inspection systems check solder quality and whether components are correctly positioned. Functional testing verifies whether the assembled board works as intended.

5. Cleaning and Coating (if needed)

For certain applications, residual flux from the soldering process needs to be cleaned off. For boards that might be exposed to harsh environments, a protective coating may be applied to enhance reliability and durability.

Even highly automated assembly processes face various challenges:

Component Miniaturization

As electronic devices shrink, so do component sizes. 0201-sized components (0.6mm x 0.3mm) have become standard, and even smaller 01005 components are gaining popularity. Handling these "micron-sized" components requires extremely high precision and stable environmental control.

Odd-Form Component Integration

Modern electronic devices often need to integrate various non-standard shaped components like connectors, switches, sensors, or large electrolytic capacitors. These odd-form components require special handling processes and tools, sometimes even manual assembly.

Thermal Management Challenges

High-power components generate significant heat, requiring special consideration for heat dissipation. The assembly process may need to integrate heat sinks, heat pipes, or other cooling solutions, adding to process complexity.

Supply Chain Fluctuations

Changes in the global electronic component supply chain can affect assembly process stability. Component shortages, extended lead times, or sudden design changes can disrupt production schedules, requiring manufacturers to respond flexibly.

Increased Automation and Artificial Intelligence

Future assembly facilities will increasingly use AI technologies to optimize production processes. Machine learning algorithms can analyze production data in real-time, predict potential defects, and automatically adjust process parameters to improve yield. Intelligent vision systems will detect minute defects invisible to the human eye.

Flexible Hybrid Electronics

This technology combines traditional rigid components with flexible substrates, stretchable circuits, and even printed electronics. Such hybrid systems can create electronic devices that can bend, stretch, or even fold, opening new possibilities for wearable technology, medical devices, and IoT sensors.

Modular Assembly Approaches

To address shortening product lifecycles and increasing demand for personalization, modular design is gaining traction. This approach breaks complex products down into standardized functional modules that can be manufactured and tested independently, then quickly assembled into final products, significantly reducing time-to-market.

Sustainable Assembly Practices

Environmental requirements are changing the component assembly industry. This includes using lead-free solders, water-based cleaning agents, recyclable packaging materials, and reducing energy consumption and waste generation. Some companies are even exploring designs that allow for component disassembly to facilitate product recycling at end-of-life.

Additive Manufacturing Integration

3D printing technology is gradually being integrated into electronic manufacturing processes. Beyond printing housings and structural parts, it's now possible to use conductive inks to print circuits directly, or even embed components within 3D-printed structures. This approach is particularly suitable for low-volume, highly customized products.

Though often viewed as just one "step" in the manufacturing process, component assembly is actually the crucial link that determines an electronic product's final quality, reliability, and performance. A well-designed circuit may fail frequently if poorly assembled, while an ordinary circuit can often demonstrate reliability beyond expectations through precise assembly processes.

As technology advances, component assembly is becoming increasingly precise and intelligent, but it always revolves around one core objective: accurately and reliably combining various electronic components into a perfectly functioning whole. Regardless of how technology changes, the pursuit of precision, reliability, and efficiency will always remain central to this field.

For electronic device manufacturers, understanding the basic principles and latest trends in component assembly not only facilitates more effective communication with suppliers but also allows for consideration of manufacturing feasibility during early design stages. This optimizes product performance, reduces production issues, and ultimately delivers better products to users more quickly.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..