Date: 2026-01-24

Let's talk about where every printed circuit board (PCB) truly begins. Before there are any intricate traces, tiny components, or solder joints, there is a humble, yet absolutely critical, raw material: the Copper Clad Laminate (CCL).

Think of it as the "foundation slab" for building a house. You wouldn't build your walls directly on the dirt; you pour a concrete slab first to create a stable, level, durable base. In electronics, you don't build your circuit directly in mid-air; you start with a Copper Clad Laminate.

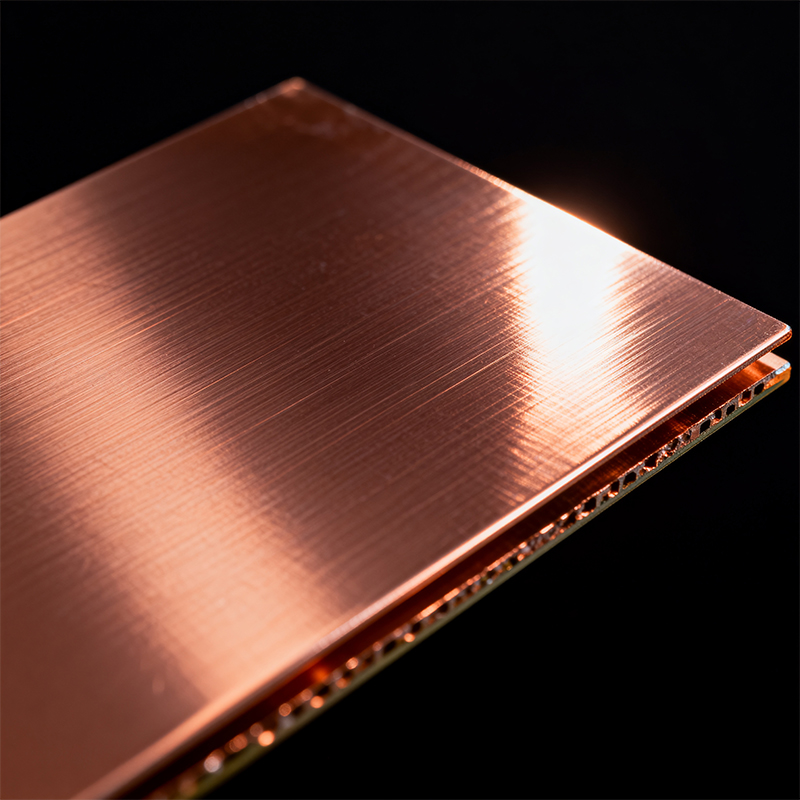

The name itself is a perfect description of what it is: a laminate (a layered sheet) that is clad (covered) with copper. It's the essential sandwich that provides both the physical structure and the electrical canvas for your design.

A standard CCL has three key parts, like a high-tech layered lunch:

The Core (Dielectric Substrate): This is the middle layer, the actual "board" material. It's an electrical insulator. The most common material by far is FR-4, a composite made from woven fiberglass cloth and an epoxy resin binder. It's strong, flame-resistant (that's what "FR" stands for), and has good electrical properties for most applications.

The Copper Foil: This is the conductive layer (or layers) bonded to one or both sides of the core. It's extremely thin—common thicknesses are like 1 ounce per square foot, which translates to about 1.4 thousandths of an inch (35 microns) thick. This is the layer that will be etched away to create your circuit's pathways (traces).

The Bonding Interface: This isn't always a separate item, but it's a critical process. The copper foil is bonded to the substrate under high heat and pressure using a special adhesive or by curing the substrate resin directly onto the foil. This bond must be incredibly strong to survive the heat, chemicals, and mechanical stress of the PCB manufacturing process.

The choice of CCL sets the stage for your entire board's performance, reliability, and cost.

It Defines the Electrical "Playground": The substrate's properties, like its Dielectric Constant (Dk), directly influence how fast electrical signals travel and how much they weaken. A poor-quality laminate can ruin the signal integrity of a high-speed design.

It Must Withstand the "Storm" of Manufacturing: The laminate has to survive being drilled, plated, exposed to harsh chemicals during etching, and baked at high temperatures during soldering. A weak laminate can warp, delaminate (layers separating), or blister.

It's the Backbone of Reliability: In the field, the CCL must endure temperature swings, humidity, and possible electrical stress without degrading. Its Glass Transition Temperature (Tg)—the point at which it starts to soften—is a key indicator of its thermal reliability.

While FR-4 is the universal standard, different applications call for different "recipes" in the laminate sandwich.

High-Frequency Laminates: For Wi-Fi, 5G, or radar circuits, standard FR-4 absorbs too much signal energy. Materials like Rogers (PTFE-based) or specialized hydrocarbon ceramics have much lower and more stable dielectric constants, keeping signals clean and fast.

High-Thermal-Performance Laminates: For power electronics or LEDs that generate lots of heat, materials with higher Tg (like FR-4 Tg170) or filled resins are used to prevent overheating and failure.

Flexible Laminates: Here, the rigid fiberglass core is replaced with a thin, bendable film like polyimide. This is the "foil" in flexible printed circuits (FPCs).

Metal-Clad Laminates (like Aluminum PCBs): In these, the substrate is a metal plate (usually aluminum) with a thin insulating layer and then copper on top. They are fantastic for spreading heat away from high-power components, commonly seen in LED lighting.

Selecting the right CCL isn't about finding the "best," but the most appropriate. Here are the key questions to ask:

What is the operating frequency of my circuit? (This is the biggest driver for moving away from standard FR-4).

How much heat will my board generate or be exposed to? (This determines needed Tg and thermal conductivity).

What is my budget? (Standard FR-4 is most economical; exotic high-frequency or thermal materials cost significantly more).

Are there any mechanical constraints? (Does it need to be thin, flexible, or extra rigid?).

The Copper Clad Laminate is the unsung starting point of every electronic device. Its quality and characteristics ripple through every subsequent manufacturing step and ultimately define the capabilities and limits of the final PCB.

Understanding CCL is not about getting lost in material science datasheets. It's about appreciating that a successful board design starts with choosing the right foundation—one that is strong enough to build on, stable enough to rely on, and tailored enough to let your electronic "house" perform exactly as you imagined.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..