Date: 2026-01-24

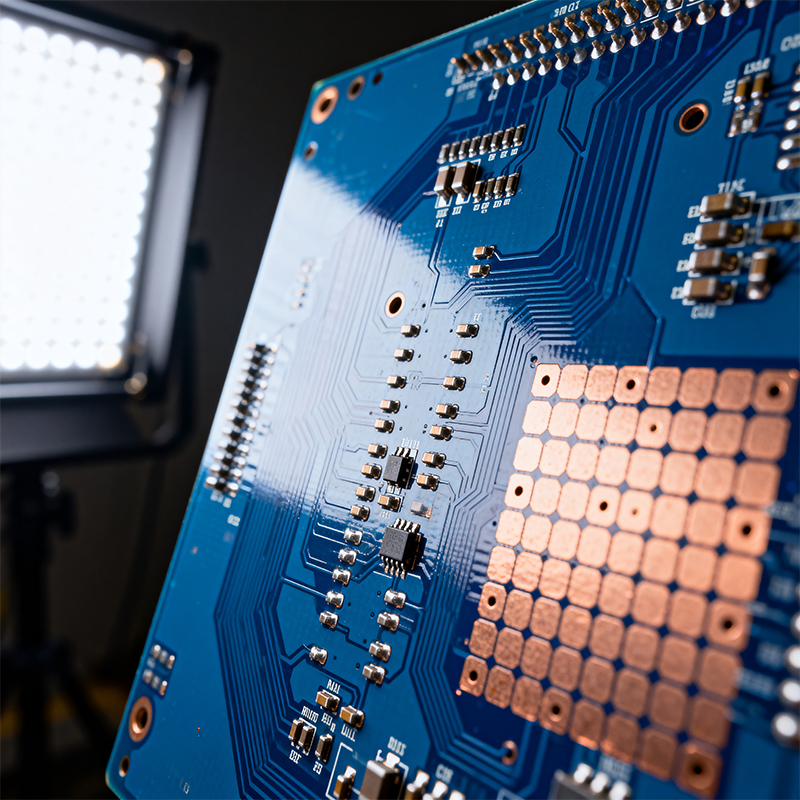

Look closely at a modern printed circuit board (PCB). What you likely see is a sea of green with islands of shiny silver or gold pads and fine white labels. That dominant green color isn't the board material itself; it's a specialized coating called the solder mask.

So, what is a solder mask? Think of it as the PCB's essential "traffic cop" and "protective raincoat" rolled into one. It's a thin, durable layer of polymer (like a high-tech lacquer) applied over the entire board, with one crucial job: to cover and protect all the copper traces, leaving open only the specific spots where electrical connections need to be made—the solder pads and holes.

This coating might seem like just for looks, but it solves some fundamental manufacturing and reliability headaches.

This is its most vital role. On dense PCBs, copper traces can run incredibly close together. During the soldering process—whether by a wave of molten solder or a reflow oven—solder is fluid and wants to flow everywhere. Without the solder mask, this solder could easily bridge between two separate traces, creating a short circuit and a dead board. The mask acts as a precise, physical barrier, corralling the solder only onto the intended pads.

Bare copper is not a fan of the real world. It oxidizes and tarnishes when exposed to air and moisture, which makes it hard to solder later and can lead to corrosion over time. It’s also vulnerable to scratches, dust, and chemical contamination during handling. The solder mask seals the copper in a protective shell, dramatically extending the board's shelf life and long-term reliability.

By providing a high-contrast background (like green under white silkscreen text), the mask makes it much easier for both automated machines and human eyes to see the board. This helps with accurate component placement and is critical for Automated Optical Inspection (AOI), where cameras scan the board for defects.

While not always the case, classic “PCB green” is the default for good reason:

History & Cost: The original resin and hardener formulations happened to produce a green color and became the industry standard, making it the most cost-effective option.

Eye Comfort: Green is easy on the eyes for technicians and inspectors who spend long hours looking at boards under bright lights.

Reliable Performance: The standard green formula is known for its excellent properties during the manufacturing process.

Today's Rainbow: You now commonly see blue, red, black, and even white solder masks. The color comes from dyes added to the base material. While the core function remains the same, the choice is often about aesthetics, branding, or specific needs—like white used behind LED arrays to reflect more light.

Solder masks are applied in different ways, each with its own strengths:

Liquid Photoimageable Solder Mask (LPSM): This is the most common method today. It's applied as a liquid, then exposed to UV light through a precise film (like developing a photograph). The UV light cures the mask, and the unexposed areas are washed away, leaving perfect openings over the pads. It's excellent for complex, high-density boards.

Dry Film Solder Mask: A solid film is laminated onto the board under heat and pressure. It's also exposed and developed similarly. It can provide a very uniform thickness but may be less suited for boards with a lot of surface variation.

In summary, the solder mask is a perfect example of an unsung hero in electronics manufacturing. This thin layer of colored polymer is what makes modern, dense, and reliable circuit boards possible. It's the reason automated assembly can run with high yields and why the electronics in your devices can last for years. The next time you see a PCB, you'll know that its iconic color is actually a sophisticated, essential piece of the manufacturing puzzle.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..