Date: 2026-02-07

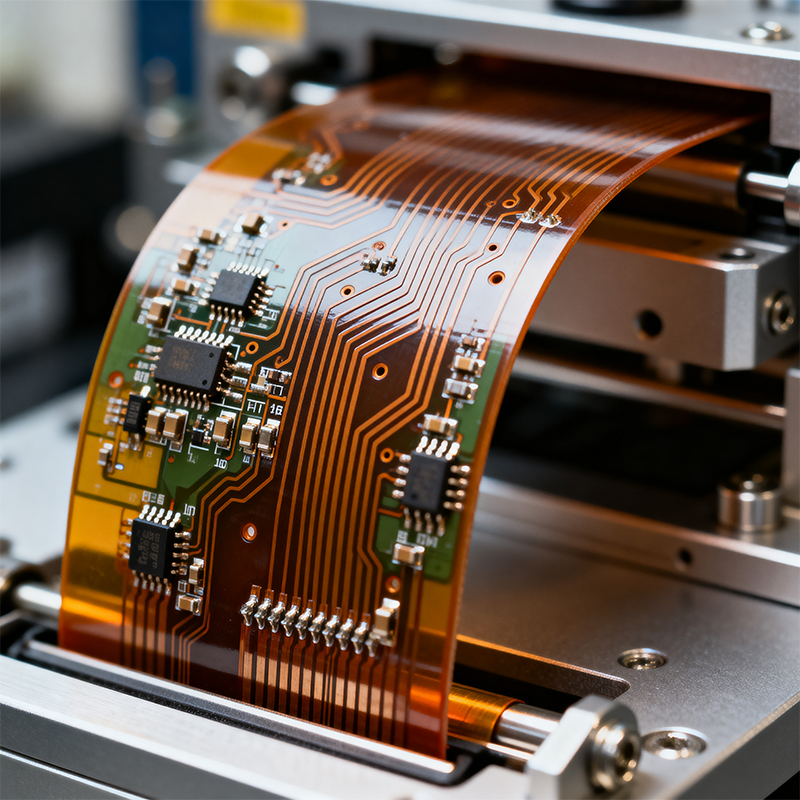

Have you ever wondered how a smartwatch can wrap comfortably around your wrist or how a modern car's dashboard display can curve so elegantly? The secret often lies in a special kind of circuit board that can bend and flex—the Flexible Printed Circuit Board, or Flex PCB.

Think of it like the difference between a rigid wooden plank and a flexible piece of fabric. Traditional rigid PCBs are the planks: strong and stable, but limited in shape. Flex PCBs are the fabric of the electronics world—thin, adaptable, and opening up entirely new possibilities for product design.

The demand for these bendable circuits is skyrocketing, with the entire PCB market projected to grow significantly, fueled in part by the need for the miniaturized, high-performance components that Flex PCBs enable. They are the unseen backbone in everything from everyday gadgets to cutting-edge technology, allowing engineers to create devices that are lighter, smaller, and more reliable.

This guide will demystify how these incredible circuits are made and explain why finding the right partner for Flex PCB fabrication is a critical step for your next-generation electronics project.

Flex PCBs aren't just a niche product anymore; they are a driving force in electronics innovation. Several key trends are pushing them into the spotlight:

The Miniaturization Wave: Consumers want devices that are sleeker and more portable. Flex PCBs can be folded into 3D shapes, saving invaluable space inside smartphones, fitness trackers, and hearables. This makes them essential for achieving the slim, modern designs we love.

Wearable and Medical Tech Boom: For a device to be worn comfortably, it needs to move with the body. Flex PCBs are ideal for smart clothing, health monitors, and even advanced medical imaging equipment because they can bend and flex repeatedly without failing.

Automotive and Aerospace Innovation: Modern cars are packed with electronics for infotainment, advanced driver-assistance systems (ADAS), and lighting. Flex PCBs are perfect for these applications because they can withstand the constant vibration and temperature changes inside a vehicle. Similarly, their light weight and durability make them suitable for aerospace applications.

The Era of AI and High-Speed Data: As artificial intelligence and high-speed computing push the boundaries of performance, the electronics inside servers and networking equipment need to be more densely packed and efficient. Advanced Flex and Rigid-Flex PCBs (which combine rigid and flexible sections) are increasingly used in these high-performance environments to manage complex routing and signals.

So, how do you turn a concept into a flexible, functioning circuit? The Flex PCB fabrication process is a precise symphony of specialized materials and controlled steps. While similar to rigid PCB manufacturing in principle, working with flexible materials like polyimide film requires unique expertise and care.

Material Selection – The Foundation: It all starts with the base material, or substrate. For most Flex PCBs, this is a thin, tough film of polyimide (often known by the brand name Kapton®). This material is chosen for its excellent flexibility, heat resistance, and electrical insulation properties. A thin layer of copper is then bonded to one or both sides of this film, forming the starting "clad" material.

Precision Imaging – Drawing the Circuit: The desired circuit pattern is transferred onto the copper layer. This is typically done using a high-precision method like Laser Direct Imaging (LDI), where a laser directly "draws" the pattern on a light-sensitive coating applied over the copper. This step defines all the fine traces and connection pads that will make up the final circuit.

Etching – Revealing the Design: The board goes through a chemical etching process. The areas of copper protected by the imaged pattern remain, while the rest is washed away, leaving behind the intricate copper pathways of the circuit.

Layer Bonding – Building Complexity: For multilayer Flex PCBs (imagine a flexible sandwich of circuits), the individual layers are precisely aligned and bonded together using layers of specialized adhesive under heat and pressure. This requires extreme precision to prevent misalignment that could cause electrical shorts or breaks.

Drilling and Plating – Making Connections: Tiny holes, called vias, are drilled (often with lasers for micro-vias) to create electrical connections between different layers of the board. These holes are then plated with copper to ensure a solid conductive path throughout the board's three-dimensional structure.

Finishing and Testing – The Final Check: A protective, flexible coating called a coverlay (similar to solder mask on rigid boards) is applied to shield the delicate copper traces. The boards are then rigorously tested for continuity, electrical performance, and durability (like bend cycle testing) to ensure they will perform reliably in your product.

The world of Flex PCB fabrication has evolved far beyond simple single-layer bendable cables. Today's leading manufacturers offer advanced solutions for the most demanding applications:

Rigid-Flex PCBs: This is a game-changer. These boards seamlessly integrate standard rigid PCB sections with flexible circuit connectors all into one unit. They eliminate the need for many connectors and cables, making devices more reliable, lighter, and compact. They are perfect for products like advanced medical scopes or robotics where a stable component needs to connect to a moving part.

High-Density Interconnect (HDI) on Flex: As devices shrink, circuits must get denser. HDI technology involves creating ultra-fine circuit traces and using micro-vias to pack incredible functionality into a tiny flexible area. This is crucial for the compact internals of foldable smartphones and high-end wearables.

High-Frequency Flex Circuits: For 5G, radar, and advanced communication systems, signal integrity is paramount. These Flex PCBs are fabricated using specialized low-loss materials that ensure high-speed signals travel through the flexible circuit with minimal degradation.

Selecting a manufacturer for your Flex PCB fabrication is a strategic decision. The complexity of the process means the lowest cost bidder often carries the highest risk of project delays, reliability issues, and failed prototypes. Here’s what truly matters:

Proven Expertise and Quality Systems: Look for a partner with a documented history of producing reliable Flex and Rigid-Flex boards. They should have stringent quality control at every stage, from inspecting raw materials to final electrical testing, ensuring a consistently high yield.

Early and Collaborative Engineering Support: The best outcomes happen when the fabricator is involved early. A partner that offers strong Design for Manufacturability (DFM) feedback can help you optimize your design to avoid costly pitfalls, improve reliability, and speed up the entire production timeline.

Full-Service Capability: Does your project stop at the bare board? A partner that also offers PCBA (Printed Circuit Board Assembly) can be a huge advantage. Having one vendor manage the entire flow from fabrication to component population streamlines communication, improves quality accountability, and can get your finished product to market faster.

Transparency and Communication: A trustworthy partner operates with transparency. They should welcome the opportunity for you to visit their factory to see their processes, quality controls, and technical capabilities firsthand. This builds confidence and fosters a true partnership.

At Kaboer, we live and breathe flexible electronics. Based in the heart of Shenzhen, the global electronics manufacturing hub, we specialize in turning complex, space-constrained design challenges into reliable, high-performance reality.

Our expertise isn't just in one area; we provide a comprehensive solution:

Advanced Flex PCB Fabrication: From simple single-layer flex to complex multilayer and Rigid-Flex boards, we master the materials and precision processes required.

HDI & High-Frequency Solutions: We build the high-density, high-speed flexible circuits that next-generation AI, communication, and automotive applications demand.

Integrated PCBA Service: Our in-house, modern PCBA factory allows us to offer true one-stop service. We can take your project from initial flex circuit design all the way through to a fully assembled, tested, and ready-to-integrate module, ensuring seamless quality control throughout.

We believe the best partnerships are built on trust and transparency. That's why we genuinely encourage our clients—especially those looking for a long-term manufacturing partner—to visit our factory in Shenzhen. See our equipment, meet our engineering team, and discuss your project face-to-face. Let's work together to build the flexible foundation for your next innovative product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..