Date: 2026-01-13

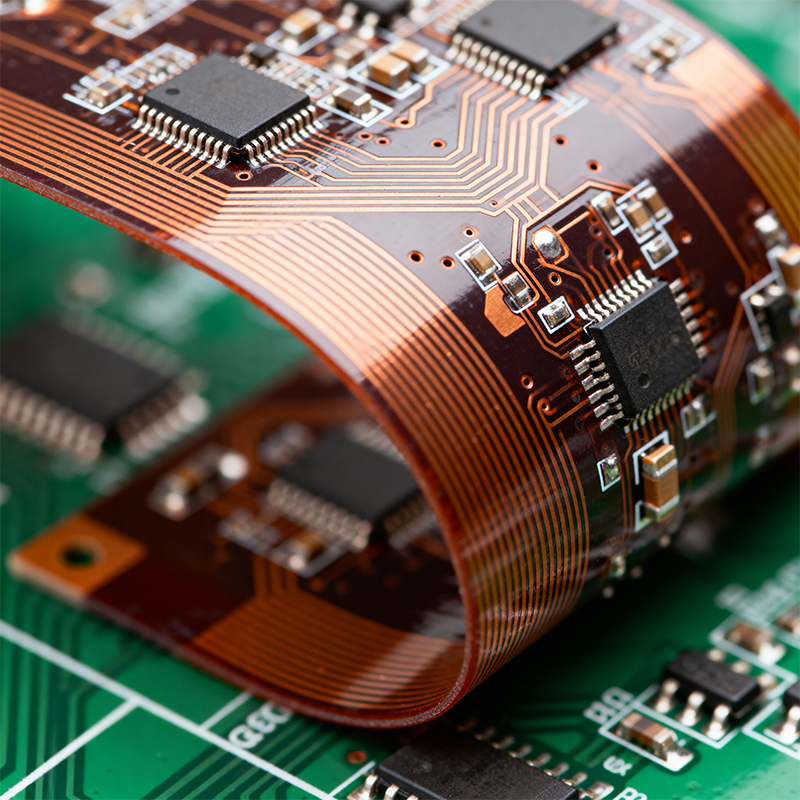

It usually starts with a physical constraint that a traditional rigid board just can't solve. Maybe the housing you’re designing has a curved surface. Perhaps you need the circuitry to bend repeatedly around a hinge, or you’re simply out of space and need to fold the electronics into a tight, three-dimensional package.

That moment of realizing “a flat board won’t work here” is what leads engineers to explore flexible PCB board options. It feels like stepping into a different world of design—one with new possibilities but also new rules. Let’s talk about what that world is really like, beyond the sales brochures.

The obvious benefit of a flexible PCB board is right in the name: it bends. This solves major mechanical headaches. But the real value comes from understanding when to use it, not just that you can.

Where flexible PCBs shine:

Replacing Harnesses: Instead of a bulky bundle of wires and connectors, a single, integrated flex circuit can connect components across moving parts (like in a laptop hinge or a robotic arm joint). It’s more reliable, lighter, and looks cleaner.

Saving Space (in 3D): You can’t just keep shrinking a rigid board. But you can fold or roll a flex circuit into unused spaces in a product’s enclosure, a game-changer for wearables and miniaturized devices.

Surviving Motion: If your product flexes, vibrates, or moves during normal use, a rigid board will eventually fatigue and crack. A flex circuit is designed for this life.

What gives designers pause:

Cost: The raw materials (polyimide) are more expensive than FR-4, and the fabrication process is more specialized. You’re paying for capability, not just square inches.

Design is a Different Animal: The rules you know for rigid boards—trace widths, spacing, component placement—all change. You now have to design for things like bend radius (how tightly it can curve without damage) and dynamic vs. static bending (will it flex once during assembly, or 100,000 times in use?).

Assembly Requires a Gentle Touch: That floppy, thin board can’t just go down a standard SMT line. It needs special carriers and fixtures to hold it flat during printing, placement, and soldering. Not every assembler has this setup or expertise.

Before you dive into a flex design, pause and answer these practical questions. They’ll save you time and money.

What’s the Primary Goal? Is it to bend repeatedly (dynamic), to fold into a shape once (static), or just to save weight and space? The answer determines your material choices, stack-up, and cost.

How Will It Be Assembled and Installed? Think about the entire journey. How will the assembler handle it? How will it be secured inside the final product—with adhesive, clips, or just tucked in? The mounting method directly impacts the stress on the board.

Can My Partner Actually Build This? This is critical. You need a manufacturer who isn’t just quoting on a drawing. They should ask you about bend radii, flex zones, and stiffener requirements. If they’re only talking about price per square inch on a flex material, they might not grasp the engineering support you’ll need.

Turning a flexible PCB design into a reliable product is where many projects stumble. The gap between a good CAD file and a working, durable flex circuit is filled with manufacturing know-how.

Common pitfalls include:

Ignoring the Neutral Bend Axis: Placing a component or a thick trace in an area that needs to bend puts stress on it, leading to cracks.

Forgetting About Stiffeners: Areas where components are mounted often need a rigid piece of FR-4 laminated on (a stiffener) to provide support for soldering and to prevent flexing where it shouldn’t.

Poor Transition Design: Where the flex meets a rigid section (in a rigid-flex design) or a connector is a critical stress point. This area needs careful reinforcement.

A good flex manufacturer will guide you through these details. They’ll look at your design and ask, “Have you considered adding tear relief here?” or “The transition at this connector looks sharp; let’s add a strain relief.”

At our factory in Shenzhen, we see flexible PCB projects not as odd exceptions, but as a regular part of advanced electronics manufacturing. We’ve learned that success comes from respecting the material’s unique nature.

Our approach is straightforward:

We Start with a Reality Check: When you share a flex concept, our engineers review it with an eye for manufacturability and long-term reliability. We’ll suggest improvements to bend areas, stiffener placement, and material thickness based on your actual use case.

We’re Equipped for the Delicate Work: Our SMT lines have dedicated carriers and pallets for flexible and rigid-flex boards. Our reflow profiles are tuned to account for the different thermal mass, preventing warping or damage to the thin material.

We Bridge the Gap to a Finished Product: We can manage the entire build—from fabricating the flexible circuit itself to sourcing components, assembling them with care, and performing rigorous testing. This means one team is accountable for making sure your delicate flex board is handled correctly every step of the way.

Choosing a flexible PCB board is an engineering decision. It’s not about being trendy; it’s about solving a specific mechanical problem that a rigid board can’t.

If your design requires bending, folding, or extraordinary space savings, then flex is likely the right technical path. The key to a smooth journey is partnering with a manufacturer who understands both the design intent and the manufacturing realities, who can be your guide rather than just your supplier. That partnership turns a complex challenge into a reliable, integrated part of your product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..